Sweet potato seedling throwing, soil covering and pressing device and sweet potato planter

A technology for sweet potatoes and potato seedlings, which is applied in planting methods, transplanting machinery, digging/covering ditches, etc., and can solve problems that affect farmers' planting enthusiasm, lack of sweet potato planting equipment, and low planting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

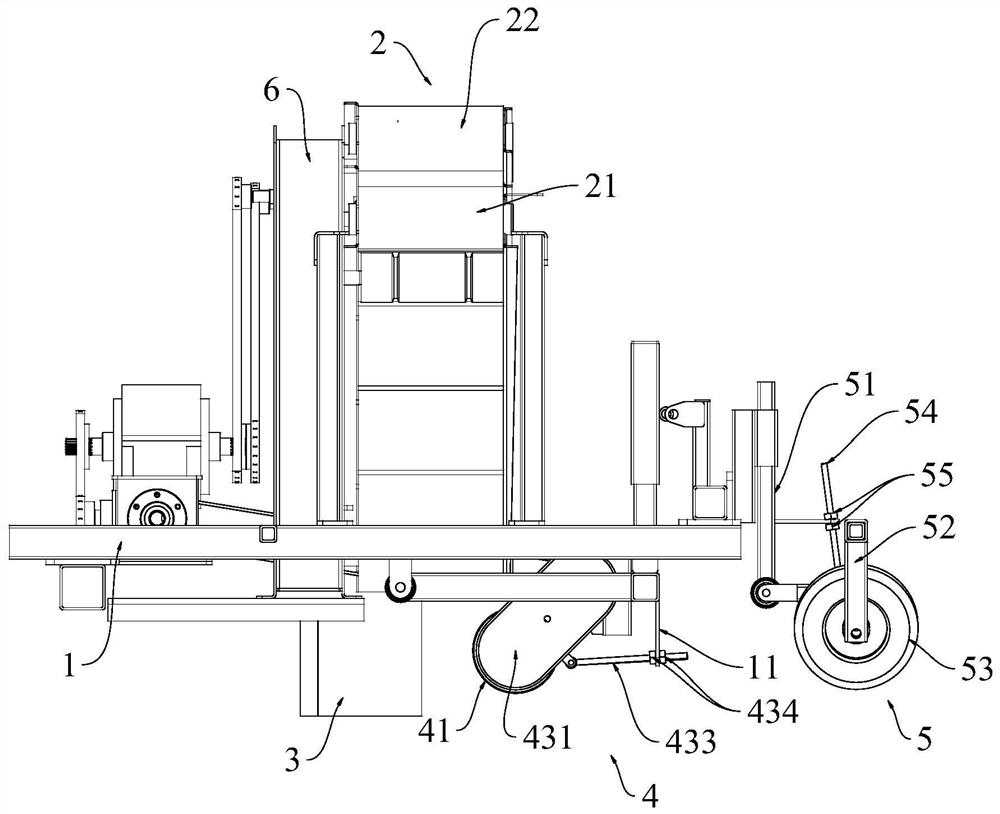

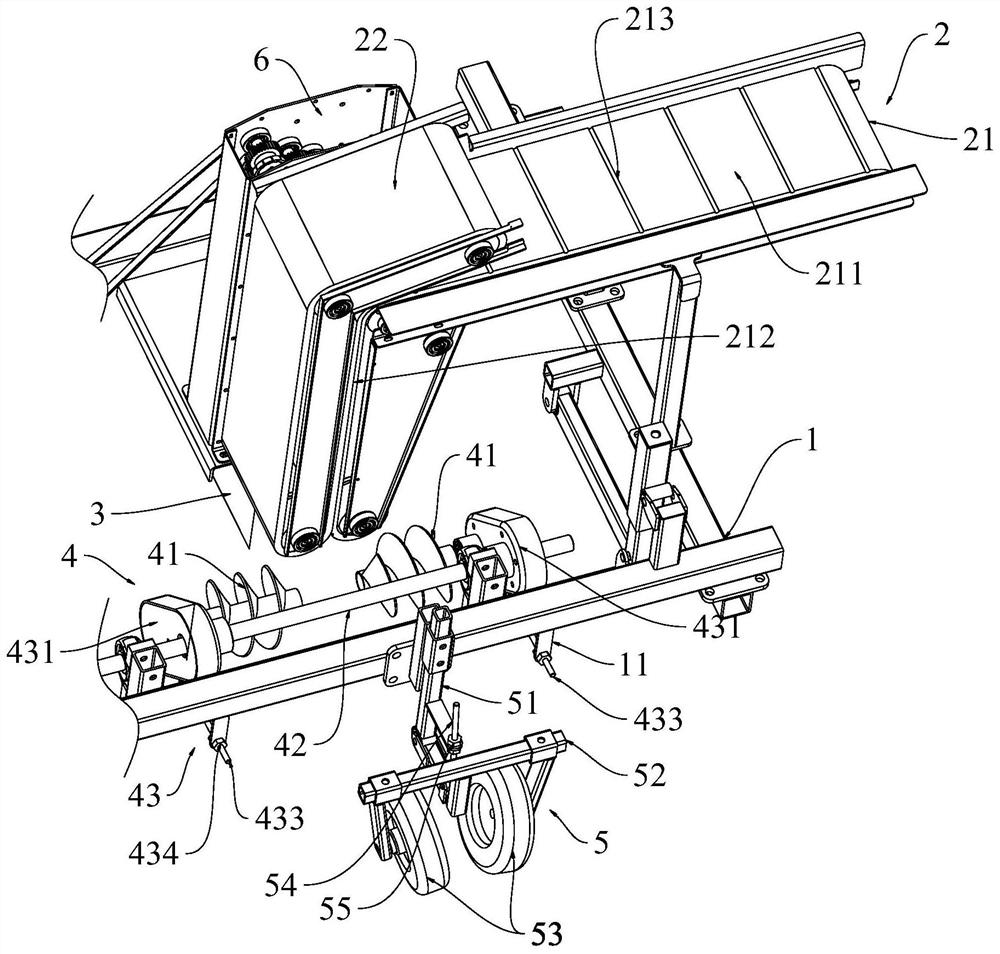

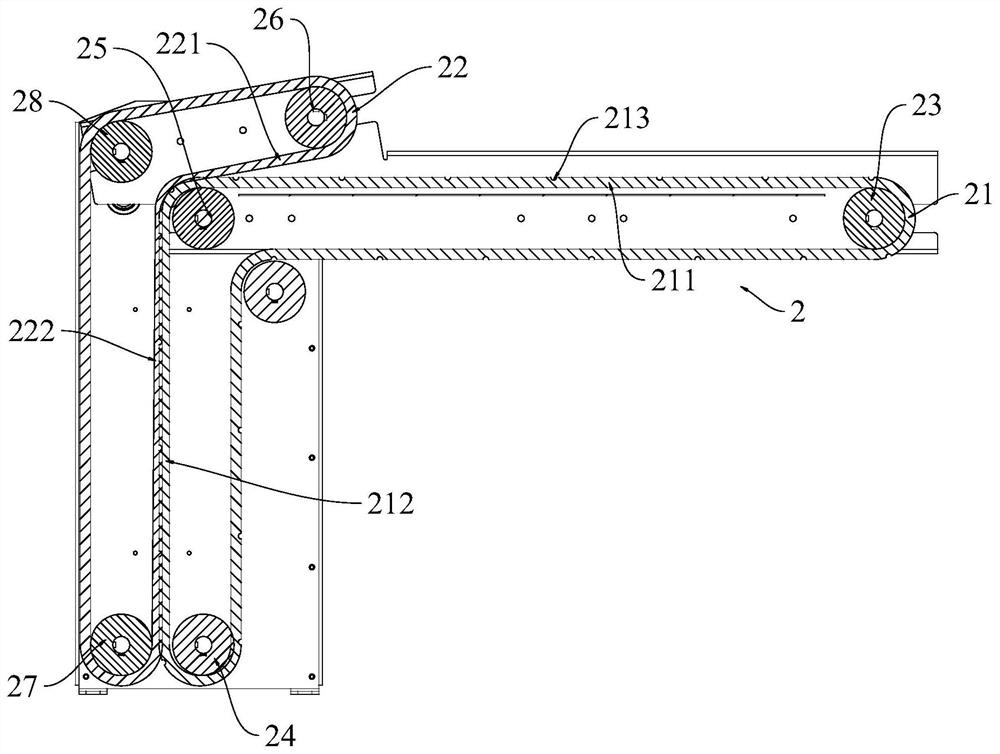

[0037] as attached figure 1 with attached figure 2 The shown sweet potato seedling throwing seedling soil-covering suppression device includes a frame 1, and the frame 1 is sequentially provided with a ditching seedling throwing assembly, a soil covering assembly 4 and a suppression assembly 5; the ditching throwing assembly includes upper and lower Sweet potato seedling throwing mechanism 2 and ditch opener 3 are provided; the middle part of ditch opener 3 has a seedling drop groove, and the feeding end of potato seedling throwing mechanism 2 is facing the drop seedling groove; 1 height adjustable.

[0038] Said device, by setting the ditch opener 3 that can open trench on the land, and above the ditch opener 3, the sweet potato seedling throwing mechanism 2 is set, and at the rear of the ditch opener 3, the soil covering assembly 4 and the pressing Component 5, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com