Automatic reciprocating double-layer folding device for dough and laminating continuous production line

An automatic reciprocating and folding device technology, applied in the fields of dough processing, baking, food science, etc., can solve the problems of affecting the quality of noodles or steamed bread, insufficient gluten network formation, and many manual processing links.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way. Any transformation or replacement based on the teaching of the present invention belongs to the protection scope of the present invention.

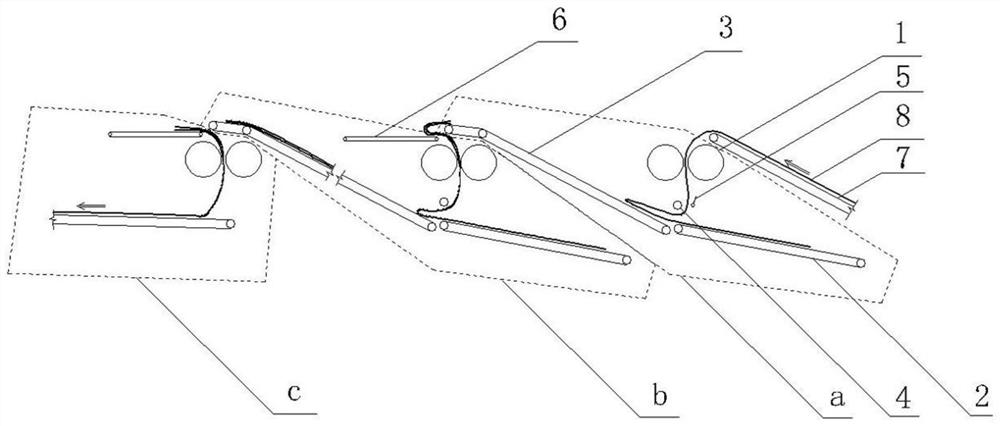

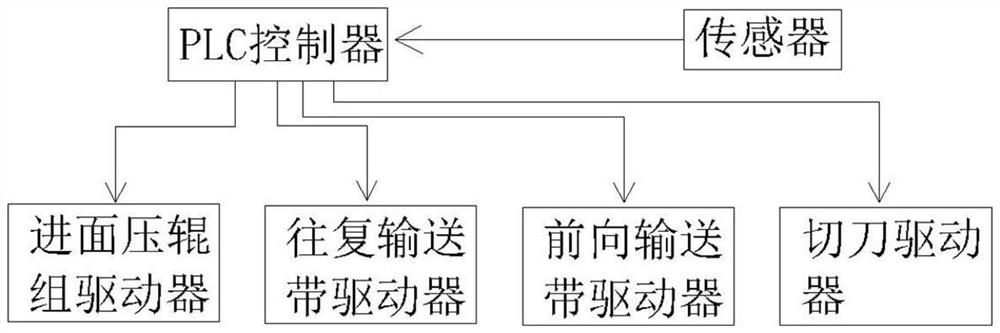

[0017] as attached figure 1 -2 shown in the present invention is an automatic reciprocating double-layer folding device for noodle blanks, including noodle-feeding roller group 1, reciprocating conveyor 2, forward conveyor 3, folding-assisting roller 4, and cutter 5 arranged on the frame , the joint end of the reciprocating conveyor 2 is located below the outlet of the face-feeding pressure roller group 1, the joint end of the forward conveyor 3 is connected to the joint end of the reciprocating conveyor 2, and the folding-assisting roller 4 is arranged on the face-in face Between the surface outlet of the pressing roller group 1 and the joint end of the reciprocating conveyor 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com