Novel wastewater treatment grid for wool textile washing and processing

A wastewater treatment and textile technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve problems such as difficult to clean wool and impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

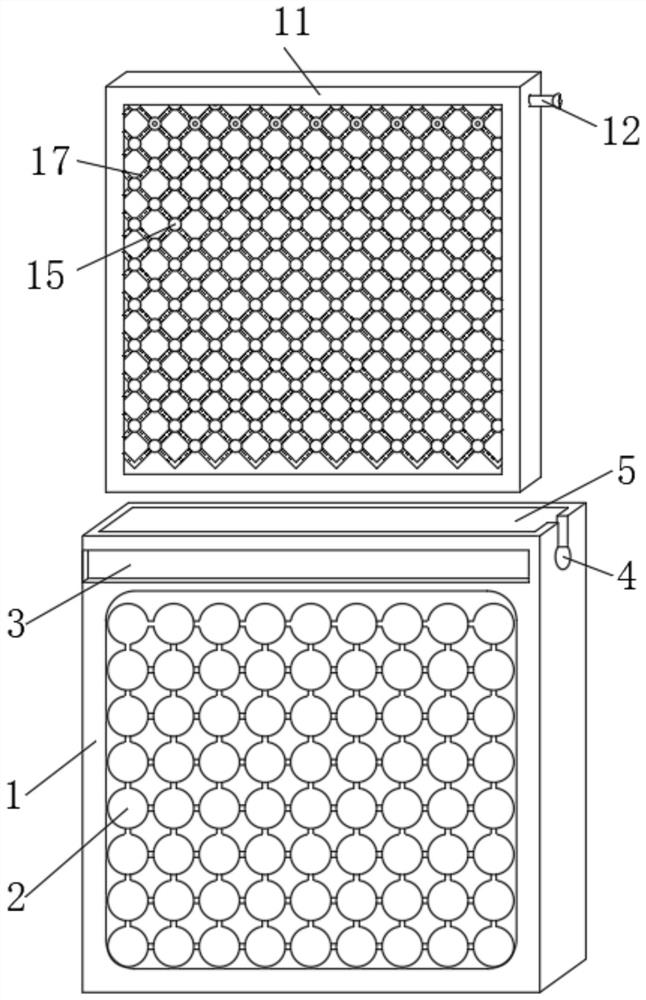

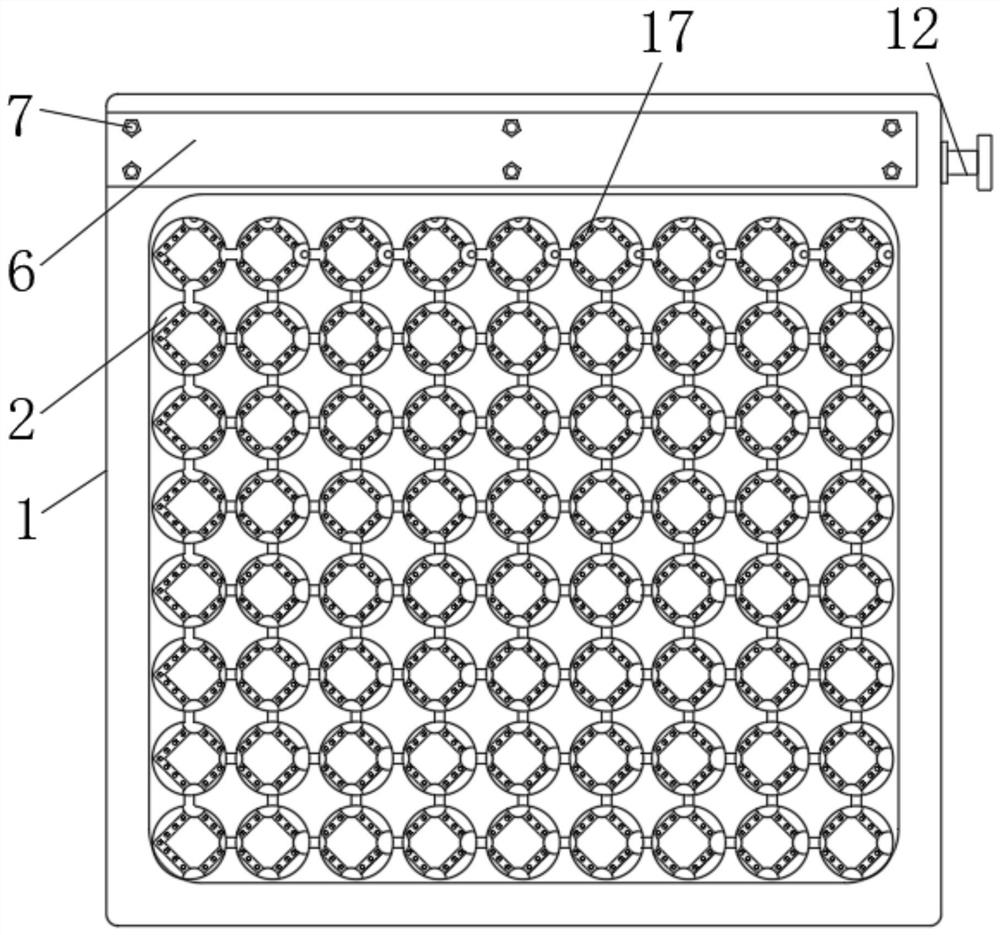

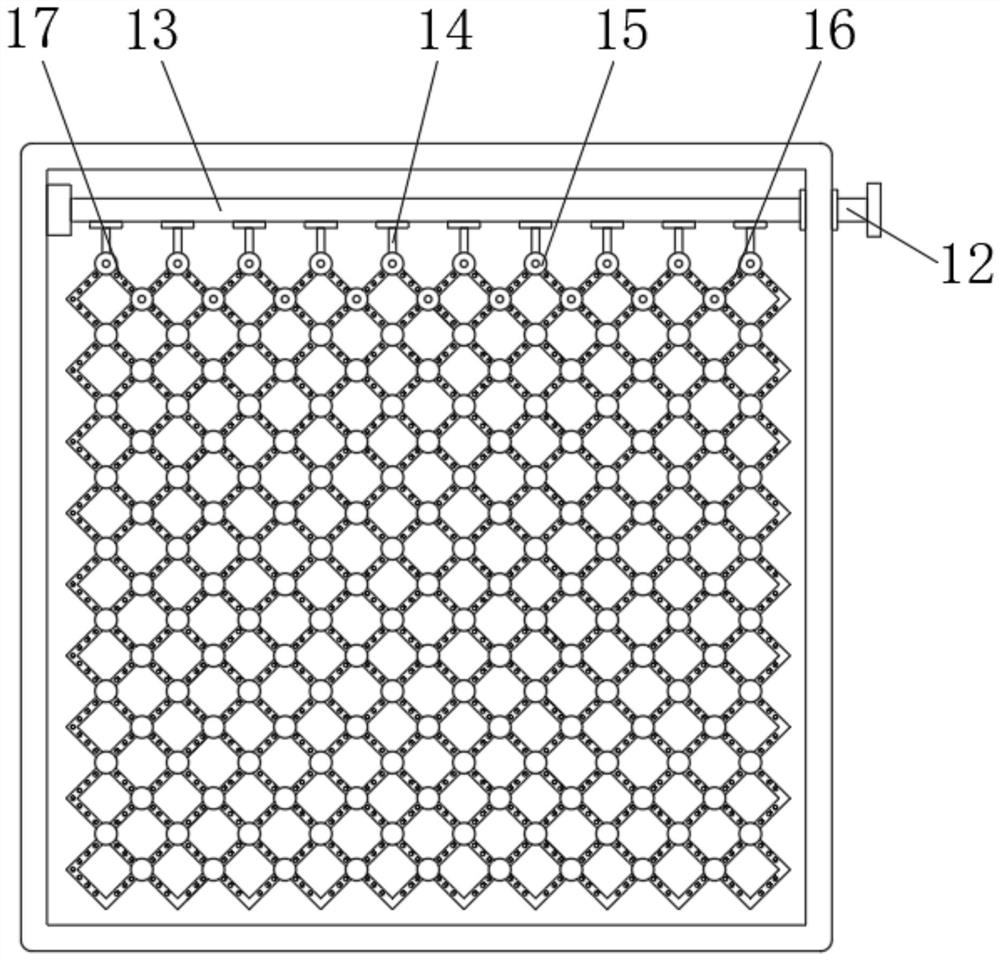

[0048] see Figure 1-9 , a new type of waste water treatment grid for wool textile washing processing, comprising a grid frame 1, the front and rear surfaces of the grid frame 1 are provided with water permeable holes 2, the upper left side of the grid frame 1 is dug with a pipeline positioning groove 4, and the water permeable holes 2 There is a placement groove 3 on the upper side, and a penetration groove 5 is opened inside the top of the grid frame 1, and a positioning panel 6 is mounted on the interior of the placement groove 3, and a locking block 7 is threaded on the front side of the positioning panel 6, The rear side of the positioning panel 6 is fixedly equipped with a wool collection shaft 8, the rear end of the wool collection shaft 8 is fixedly installed with an elastic ball 9, the rear end of the elastic ball 9 is fixedly installed with a pick 10, and the inside of the penetration groove 5 is provided with a disassembly frame 11. Disassemble the frame 11, the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com