Integrated environment-friendly frame structure of stirring plant

A frame structure and integrated technology, which is applied in the direction of cement mixing device, liquid ingredient supply device, sales raw material supply device, etc., can solve the problems of low space utilization rate and complex frame structure of the mixing building, so as to reduce the basic cost and improve production The working environment is conducive to the effect of design and construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

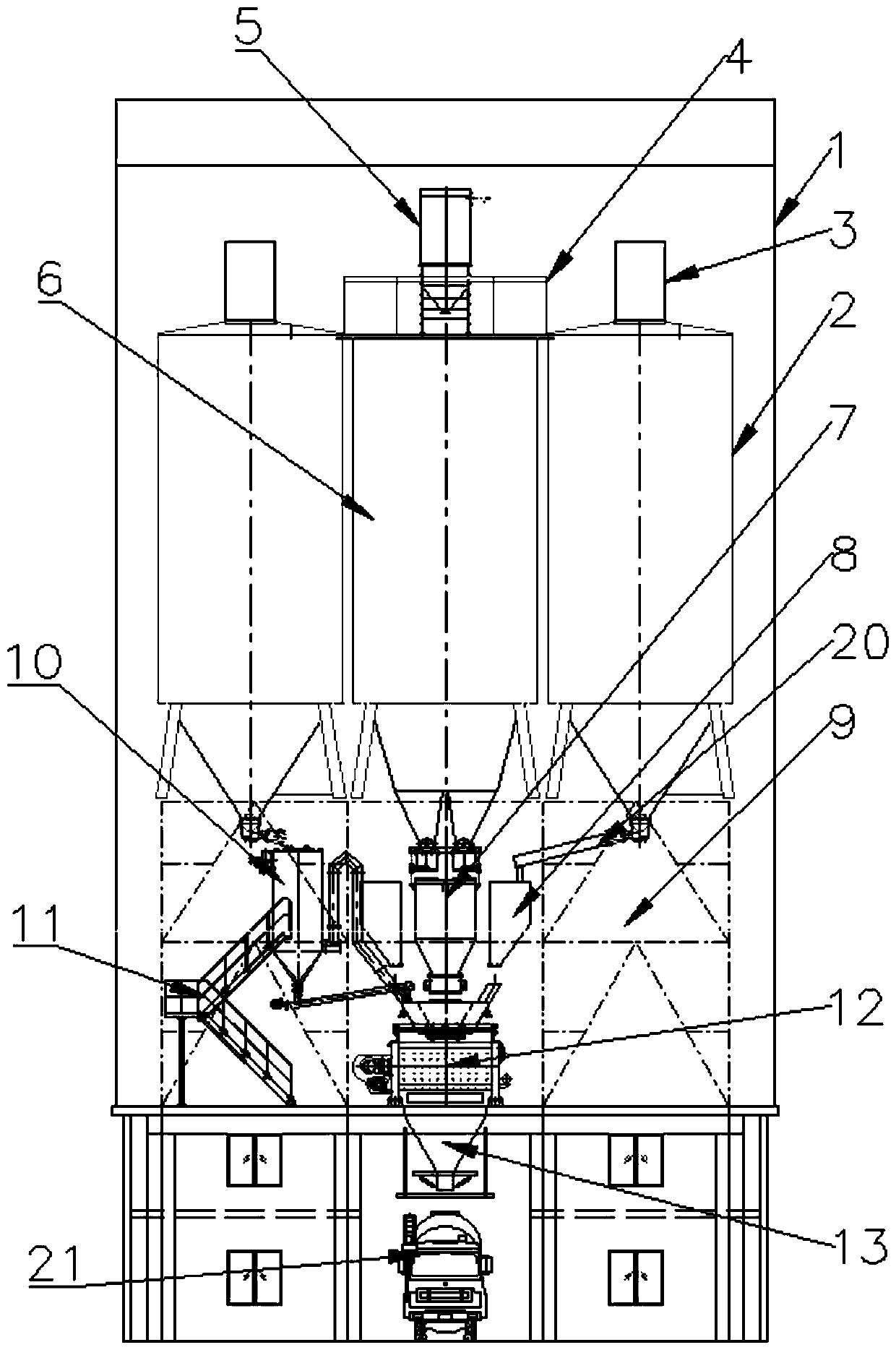

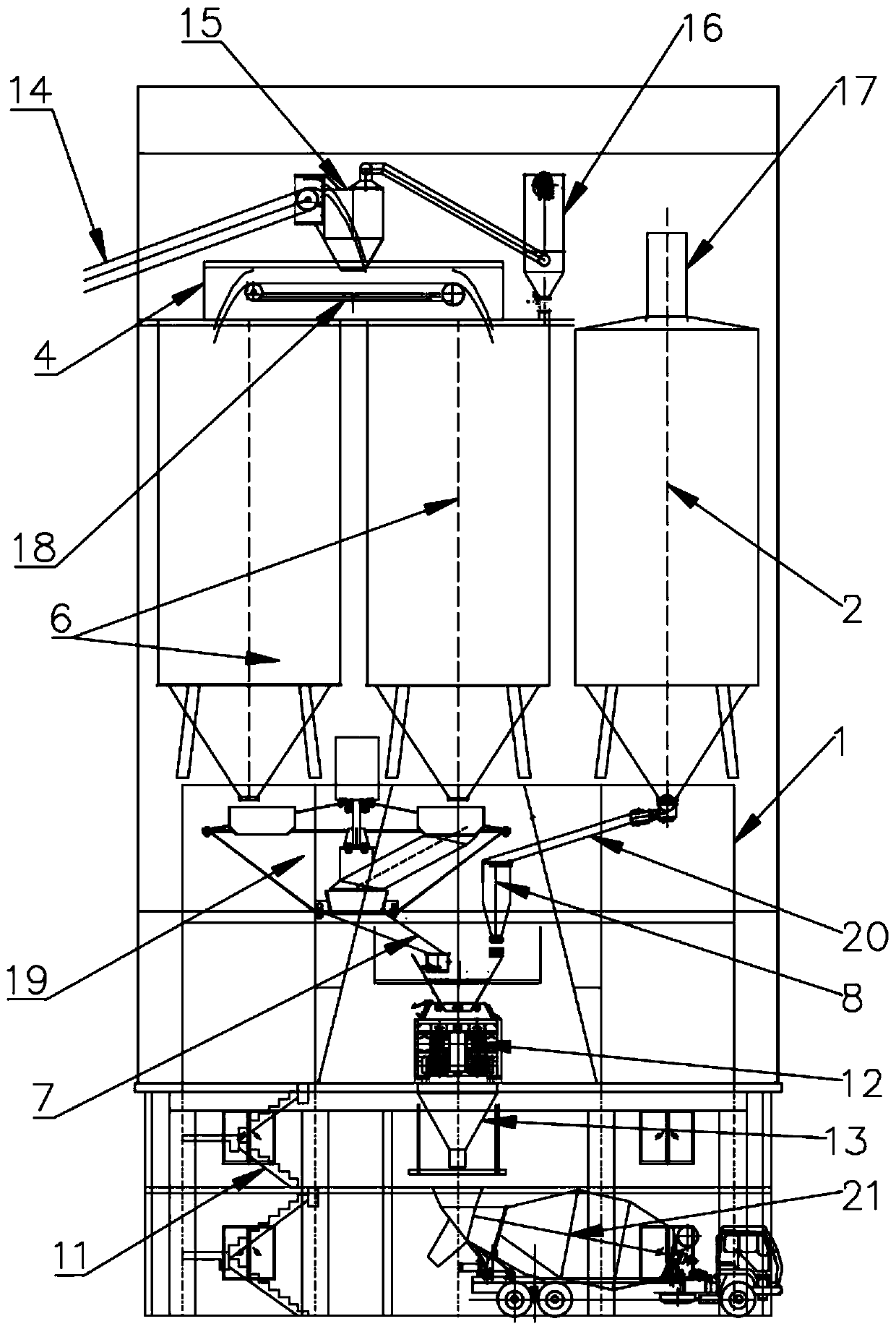

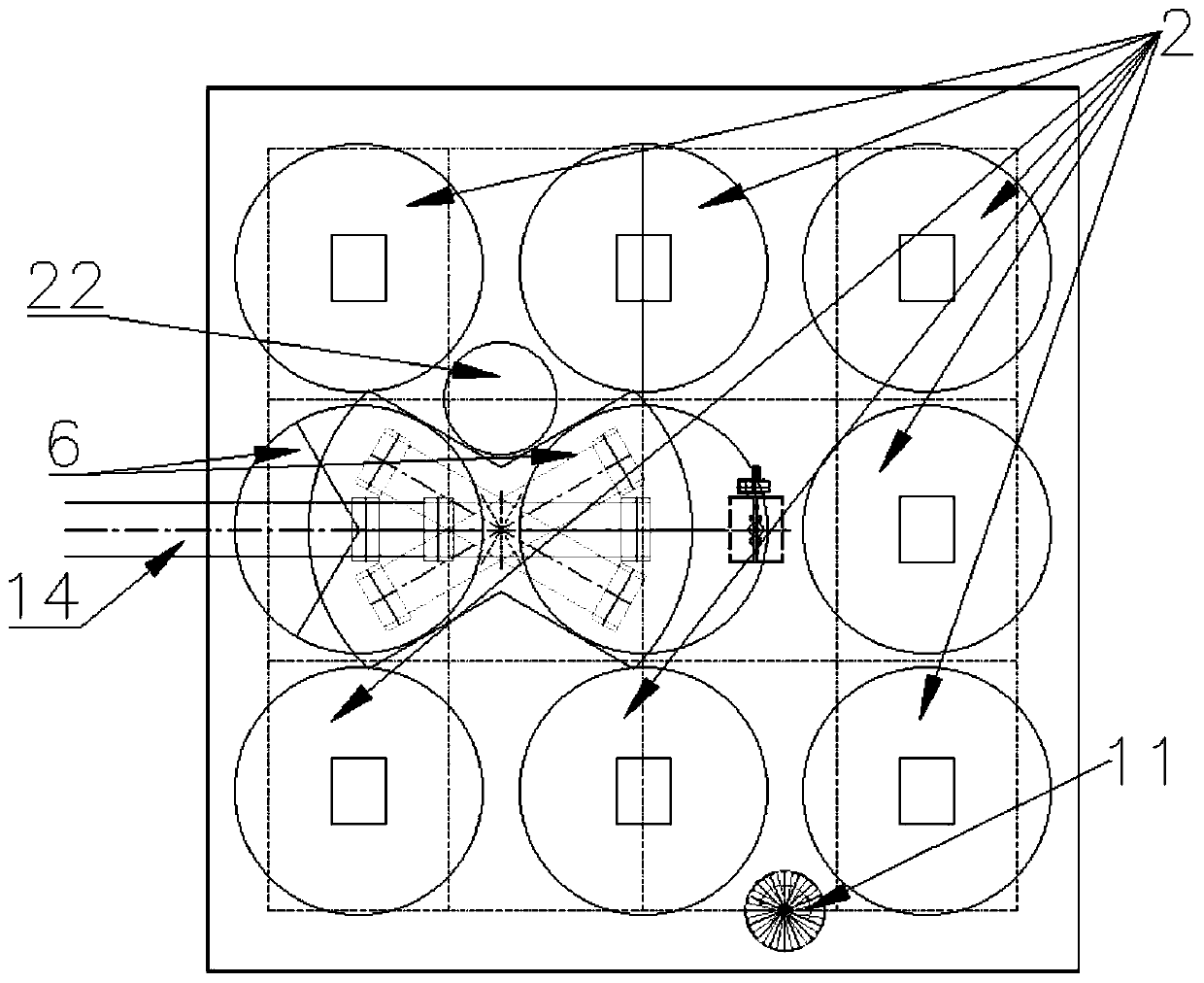

[0035] Such as figure 1 As shown, an integrated environment-friendly frame mixing building frame structure includes an integrated frame 1, and the integrated frame 1 is an I-shaped steel frame beam structure, which is used to fix each component inside the integrated frame 1. The integrated frame 1 A silo is installed on the top, and the silo includes a powder silo 2 and an aggregate silo 6, and the supporting structures of the powder silo 2 and the aggregate silo 6 are located on the same plane formed on the top of the integrated frame. In addition, a plurality of small storage bins 22 are also provided in the description, for simplifying the accompanying drawings, image 3 Only one small storage bin is shown in , but actually includes a plurality of small storage bins 22, and the small storage bins are used to store water, liquid admixture or powdered additive.

[0036] The top of the powder silo 2 is equipped with a pulse dust collector 17 on the top of the powder silo to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com