Intelligent coal saving, emission reduction and synergy integrated system for gas producer

A technology of coal gasifier and integrated system, which is applied in the direction of gasification process, chemical industry, and manufacture of combustible gas, etc. It can solve the problems of increased nitrogen oxide emissions, decreased production, adjustment and maintenance obstacles, etc., and achieves the reduction of CO and NO emissions, improve gas quality, and prevent thermal energy from spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

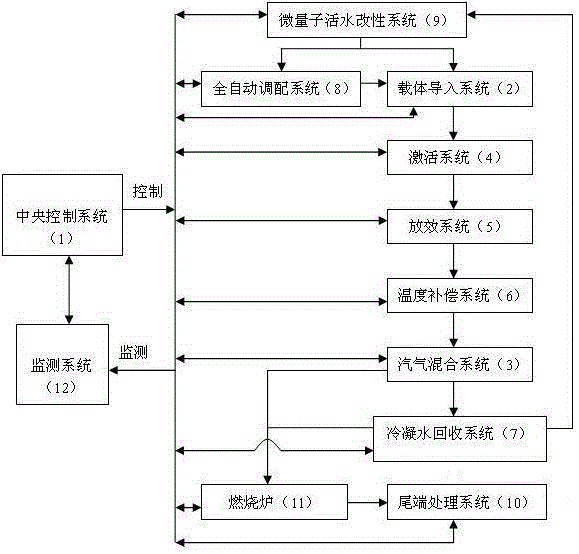

[0048] An intelligent coal-saving, emission-reducing, efficiency-enhancing integrated system for a coal gasifier, which includes a central control system (1), a monitoring system (12), a carrier introduction system (2), a steam-gas mixing system (3), and an activation system (4 ), release effect system (5), temperature compensation system (6), condensed water recovery system (7), fully automatic deployment system (8), micro-quantum active water modification system (9), tail end treatment system (10) and combustion furnace (11);

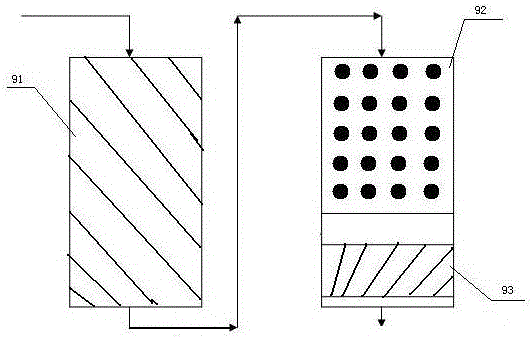

[0049] The micro-quantum running water modification system (9) and the condensed water recovery system (7) make the recovered condensed water return to the micro-quantum running water modification system (9), and the micro-quantum running water modification system (9) is then connected to the fully automatic deployment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com