Light bleaching method of composite non-woven fabric

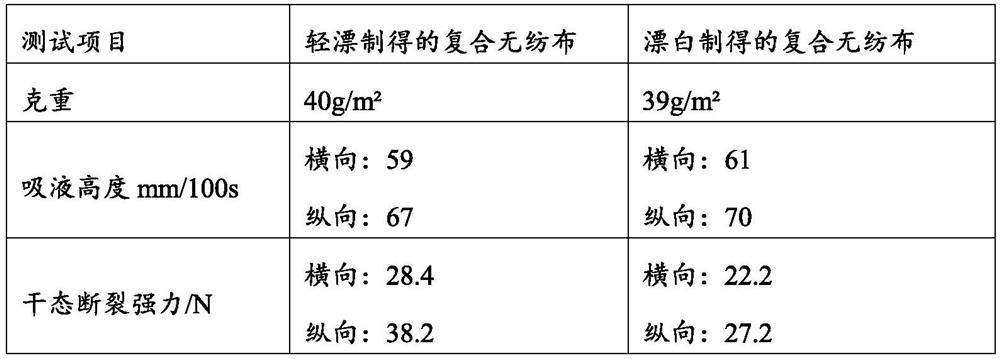

A non-woven, light-bleaching technology, applied in textiles, papermaking, dry-cleaning fiber products, etc., can solve the problems of uneven distribution of hydrophilic and water-repellent, dirty composite non-woven fabrics, large labor and material resources, etc. To the extent of reducing oxidation and other ineffective decomposition, retaining soft feel, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

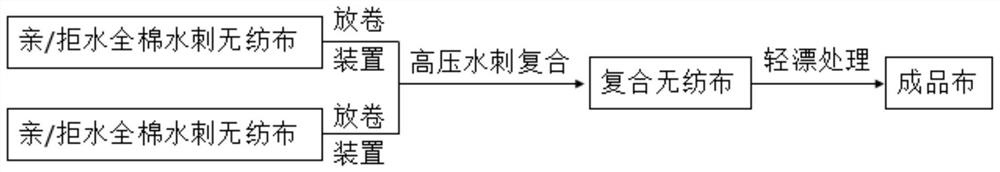

[0050] The light bleaching treatment method of the composite non-woven fabric comprises:

[0051] Step S1, pre-preparation: Both the hydrophilic cotton spunlace non-woven fabric and the water-repellent cotton spunlace non-woven fabric are unwound, and the hydrophilic cotton spunlace non-woven fabric and the water-repellent cotton spunlace non-woven fabric Cotton spunlace non-woven fabrics are combined with high-pressure spunlace to obtain composite non-woven fabrics.

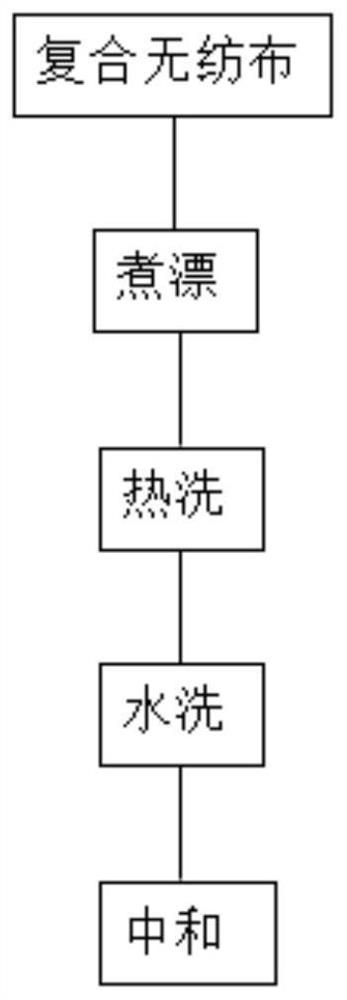

[0052] Step S2, the bleaching step: adding bleaching liquid into the bleaching pot, soaking the composite non-woven fabric in the bleaching liquid for bleaching, the bleaching liquid includes demineralized water, liquid caustic soda and hydrogen peroxide, the concentration of hydrogen peroxide is 17.5%, liquid caustic soda The concentration is 25%, the cooking and bleaching temperature is 80°C, and the cooking and bleaching step time is 45s. 3% refining agent, 8% oxygen bleaching stabilizer and 3% oxygen bleach...

Embodiment 1

[0056] Step S1, pre-preparation: Both the hydrophilic cotton spunlace non-woven fabric and the water-repellent cotton spunlace non-woven fabric are unwound, and the hydrophilic cotton spunlace non-woven fabric and the water-repellent cotton spunlace non-woven fabric Cotton spunlace non-woven fabrics are combined with high-pressure spunlace to obtain composite non-woven fabrics.

[0057] Step S2, bleaching step: add bleaching solution to the bleaching pot, soak the composite non-woven fabric in the bleaching solution for bleaching, the bleaching solution includes demineralized water, liquid caustic soda and hydrogen peroxide, the concentration of hydrogen peroxide is 30%, the concentration of liquid caustic is 25%, The boiling and bleaching temperature is 100°C, and the cooking and bleaching step time is 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com