Pulping agent and its application production method

A production method and pulping technology, which are applied in pulp beating/refining method, pulp bleaching, lye regeneration, etc., can solve the problems of high environmental pollution load, difficulty in stable discharge, and waste of resources in the pulp and paper industry. Achieve the effect of shortening pulping time, saving evaporation energy consumption, and saving water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The chemical formula (weight percentage) of the pulping agent of the present invention is:

[0056] Soda ash 10%; NaOH 10%; chlorine dioxide 8%; silicate stabilizer 3%; cooking aid 5%, the balance is water. The cooking aids are magnesium salt 1%; hydrochloric acid 0.2%; acetic acid 93%.

[0057] The cooking aid is a 5% white turbid emulsion prepared from raw materials.

[0058] The above-mentioned main raw materials and cooking aids are added to the mixed heater, and they can be prepared after 1 hour of reaction.

[0059] This formula is suitable for pulping bagasse, agricultural straw and grass fiber.

Embodiment 2

[0061] The chemical formula (weight percentage) of the pulping agent of the present invention is:

[0062] Soda ash 14%; NaOH 15%; chlorine dioxide 11%; silicate stabilizer 5%; cooking aid 8%, the balance is water. The cooking aids are ammonium salt 2%; hydrochloric acid 0.5%; acetic acid 93%.

[0063] The cooking aid is made up of raw materials into 8% white turbid emulsion.

[0064] The above-mentioned main raw materials and cooking aids are added to the mixed heater, and they can be prepared after 1 hour of reaction.

[0065] This formula is suitable for wood fiber pulping.

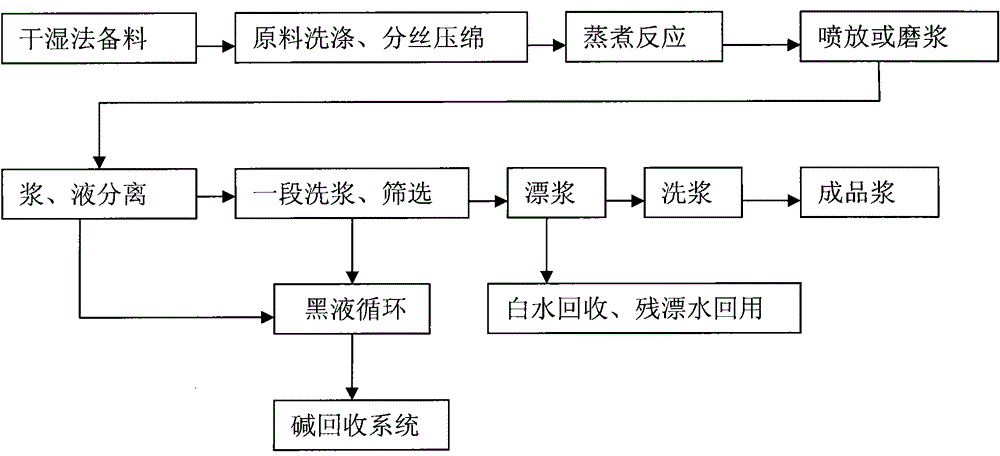

[0066] The application production process of the pulping method of the present invention:

[0067] Example 1:

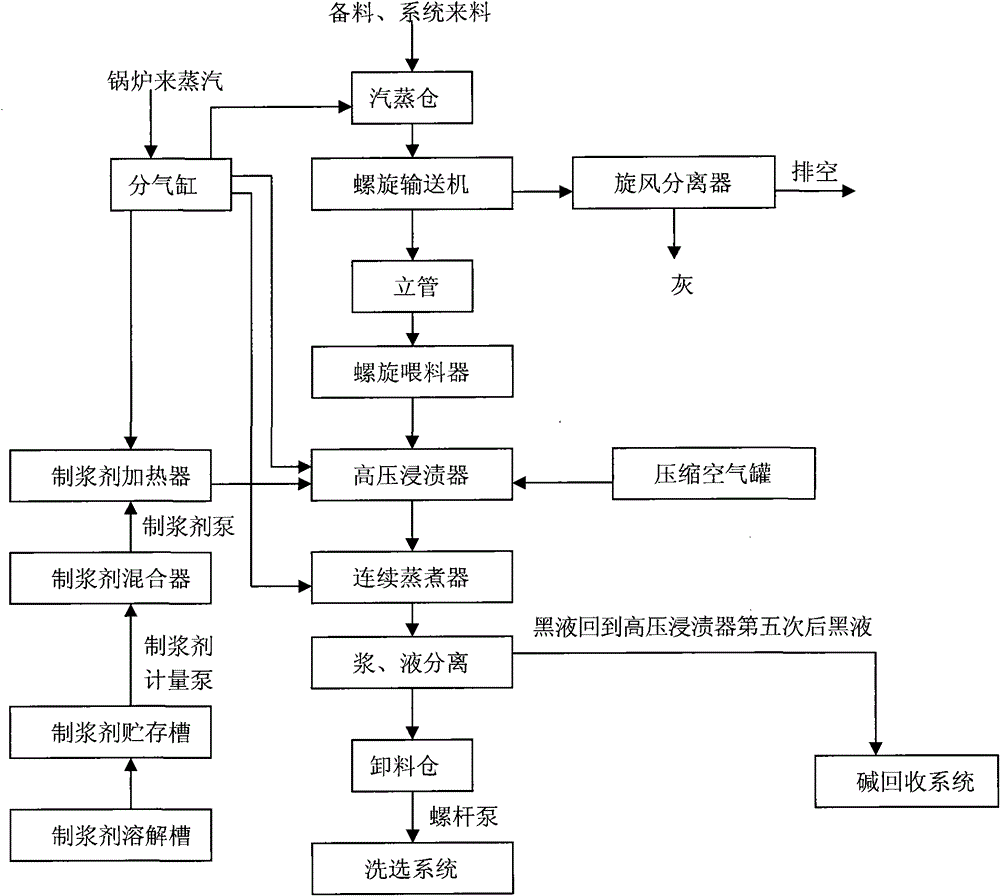

[0068] Bagasse is used as a raw material, and the reaction is cooked under normal temperature and pressure for 50 minutes, and the ratio of the raw material to the slurrying agent is 1:3, and the pulping production process is consistent with the application production process of the energy-saving and em...

Embodiment 3

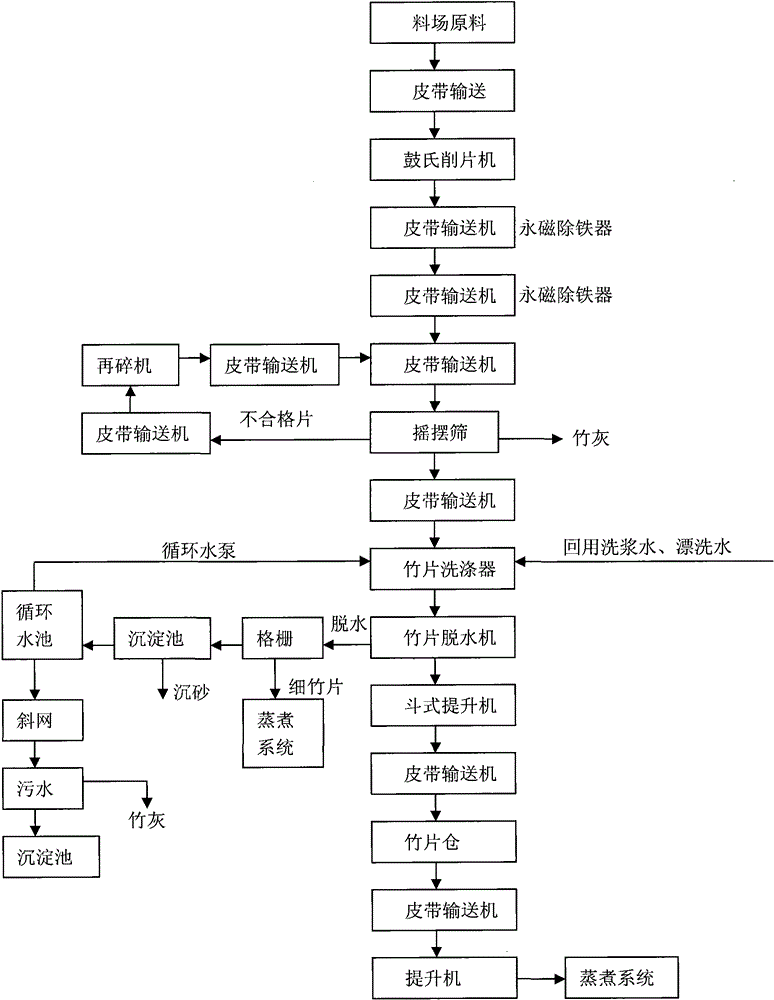

[0072] Using bamboo as the raw material, cooking and reacting at a temperature of 135°C and a pressure of 2 kg for 20 minutes, the ratio of the raw material to the slurrying agent is 1:5, and the production process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com