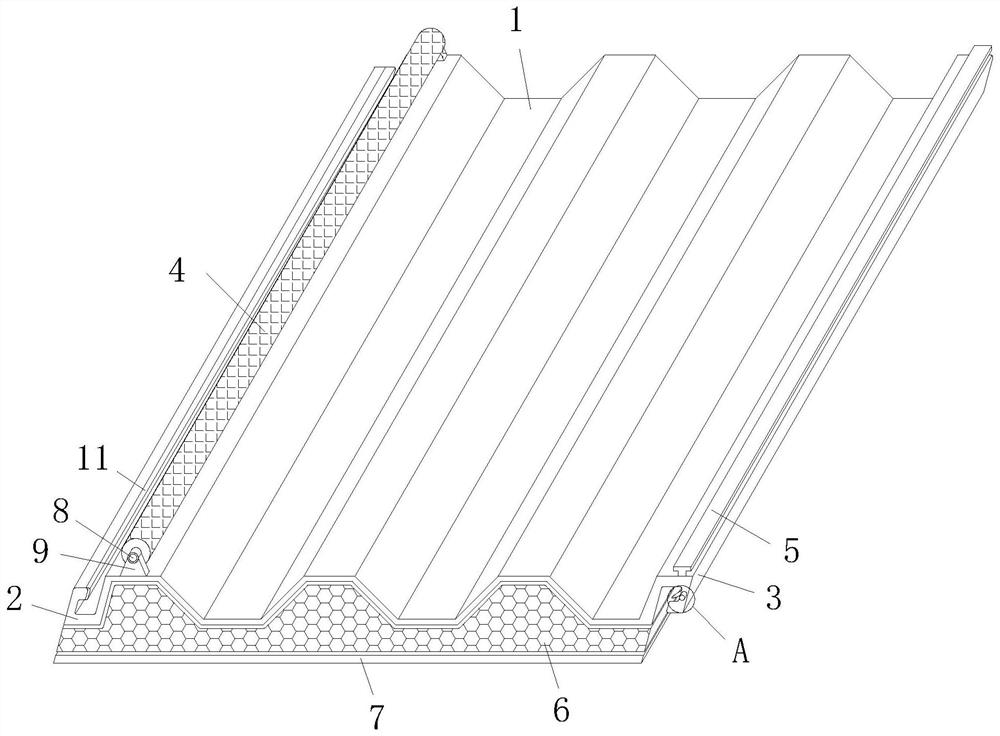

A laminated color steel plate

A color steel plate and cladding technology, which is applied to floors, building components, building insulation materials, etc., can solve the problems of difficult secondary use of color steel plates, perforation of the color steel plate body, time-consuming and laborious disassembly, etc., to save the use area, Improved fixing strength and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

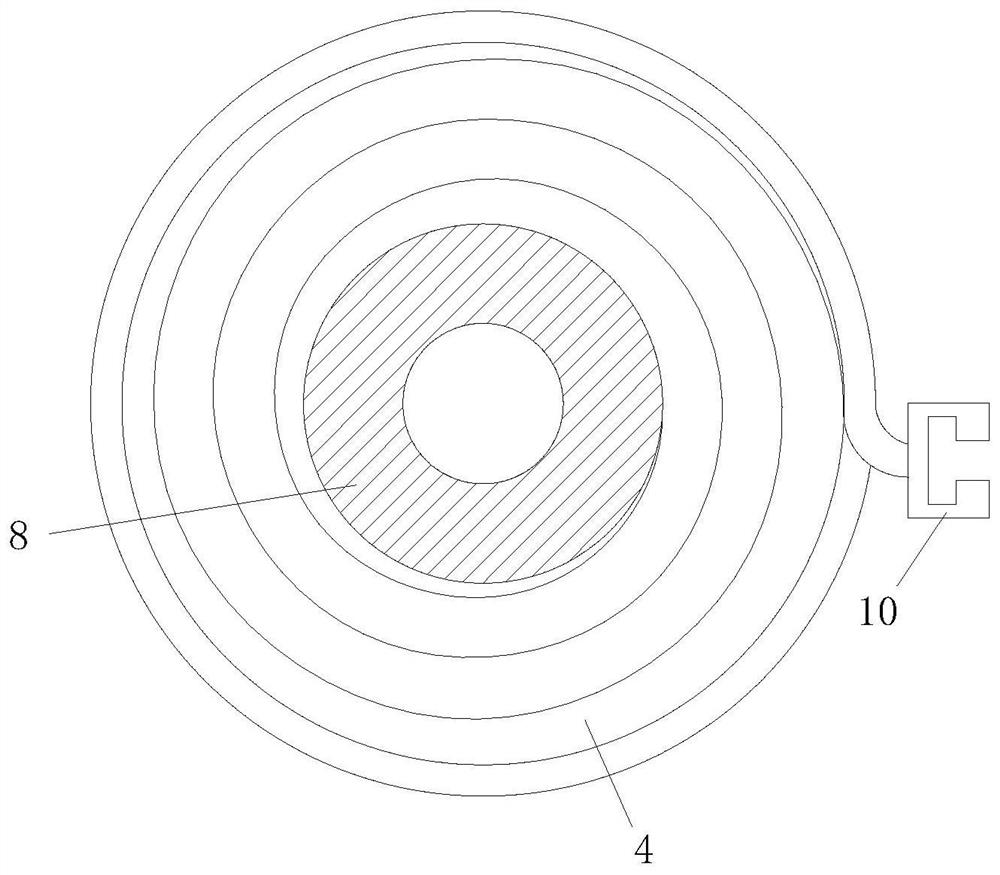

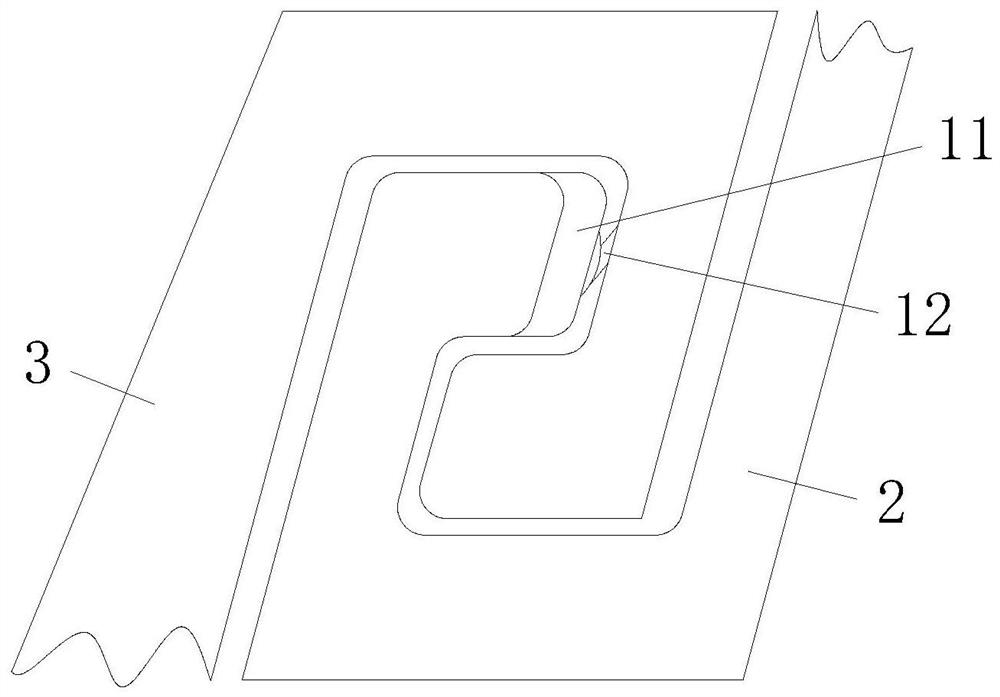

[0025]As an embodiment of the present invention, the end of the first clamping plate 2 is fixedly connected with a slant plate 11; The extrusion strength of the first clamping plate 2 and the second clamping plate 3 increases as the degree of overlap increases; the corresponding positions of the second clamping plate 3 and the inclined plate 11 are fixedly connected with uniformly arranged rubber rods 12; the rubber rods 12 Downward inclined design; when working, the second clamping plate 3 slides to the interior of the first clamping plate 2 through the inclined design of the inclined plate 11, so that the second clamping plate 3 squeezes the inclined plate 11 during the sliding process, effectively improving The fixing strength of the first clamping plate 2 and the second clamping plate 3 prevents the first clamping plate 2 and the second clamping plate 3 from detaching, causing the color steel plate 1 to fall, the safety factor is high, and the slant plate 11 can reduce rain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com