Rotational flow pump impeller for blade fixing through guide rails

A technology for fixing blades and guide rails, which is applied to pumps for special fluids, parts of pumping devices for elastic fluids, pumps, etc., and can solve problems such as reducing the efficiency of swirl pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

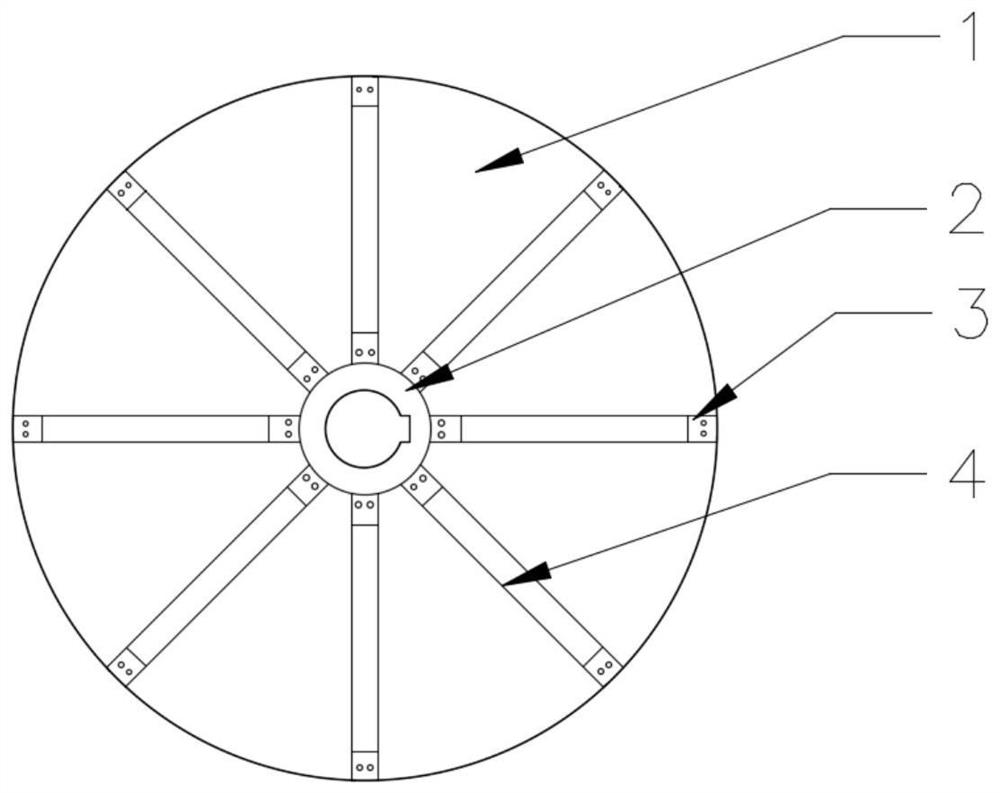

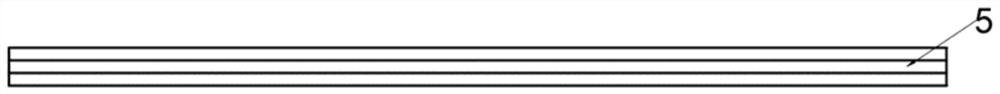

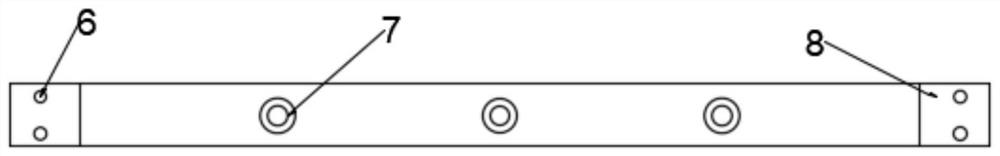

[0020] Such as Figure 1 to Figure 5 As shown, a semi-open impeller with guide rail fixed blades according to the present invention includes a rear cover plate 1, a hub 2, guide rails 3 and blades 4, and the guide rail 3 is provided with guide rail installation grooves 5, bolt holes 6, Counterbore 7 and step 8, described counterbore 7 is set on described guide rail mounting groove 5, and described step 8 is arranged on the side of described counterbore 7, and described bolt hole 6 is arranged on described step 8, The blade 4 is provided with a blade installation groove 9 .

[0021] Preferably, there are 8 guide rails 3 in total, specifically, 8 guide rails 3 are evenly distributed on the rear cover 1 .

[0022] Preferably, the diameter of the bolt hole 6 is 5mm.

[002...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap