Microstructure lens array and space positioning method based on microstructure lens array

A lens array and microstructure technology, applied in the field of optics, can solve the problems of conventional lens arrays such as low precision, large lens size, unfavorable positioning system miniaturization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An embodiment of the present invention provides a microstructure lens array. The microstructure lens array includes at least two microstructure lenses. The microstructure lens includes a plurality of prism cells. The prism cells include a silicon dioxide substrate and The titanium oxide prisms on the substrate include: a plurality of prism cells are arranged periodically.

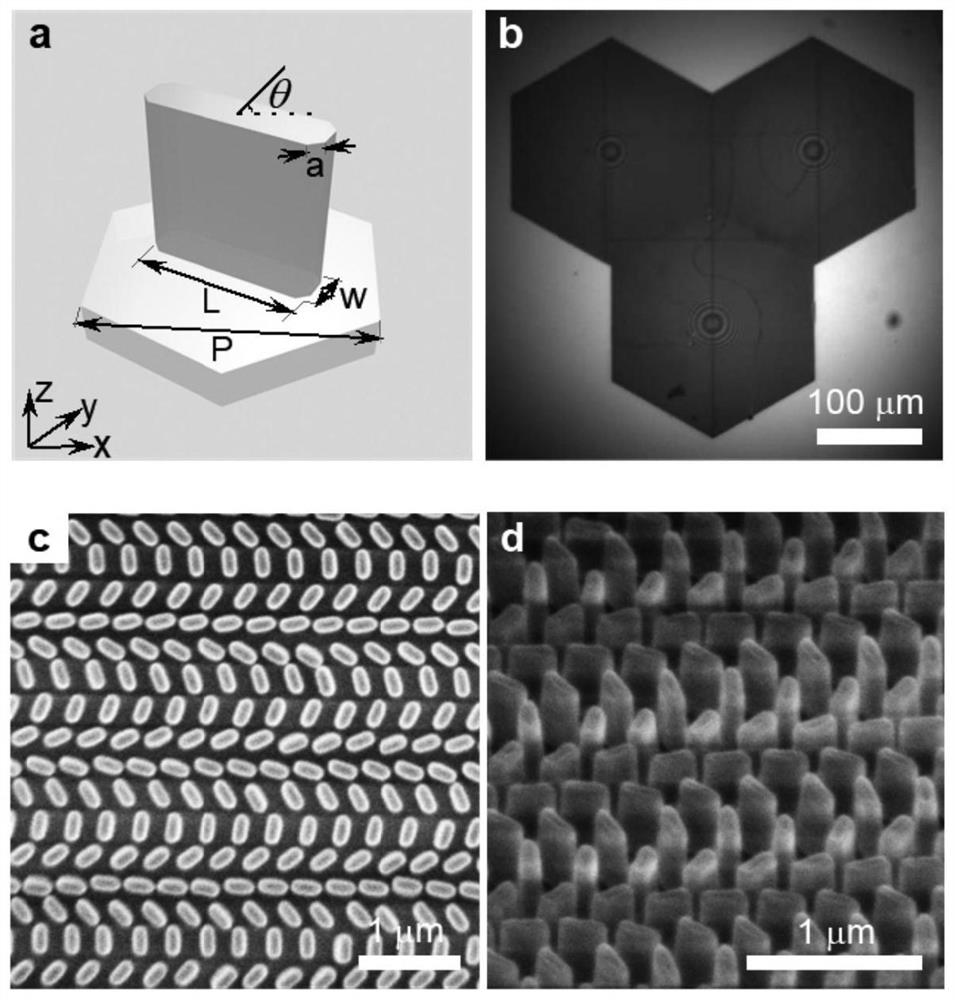

[0024] Optionally, figure 1 is a structural schematic diagram of a microstructure lens array provided according to an embodiment of the present invention, wherein, figure 1 Figure a in the figure is a schematic diagram of the structure of the prism cell of the microstructure lens array. Such as figure 1 As shown in Figure a, the titanium oxide prisms are titanium oxide octagonal prisms, and the silicon dioxide substrate is a regular hexagonal structure.

[0025] Specifically, as figure 1 As shown in Figure a, the titanium oxide prism is obtained by cutting four ribs in the z direction (cutting le...

Embodiment 2

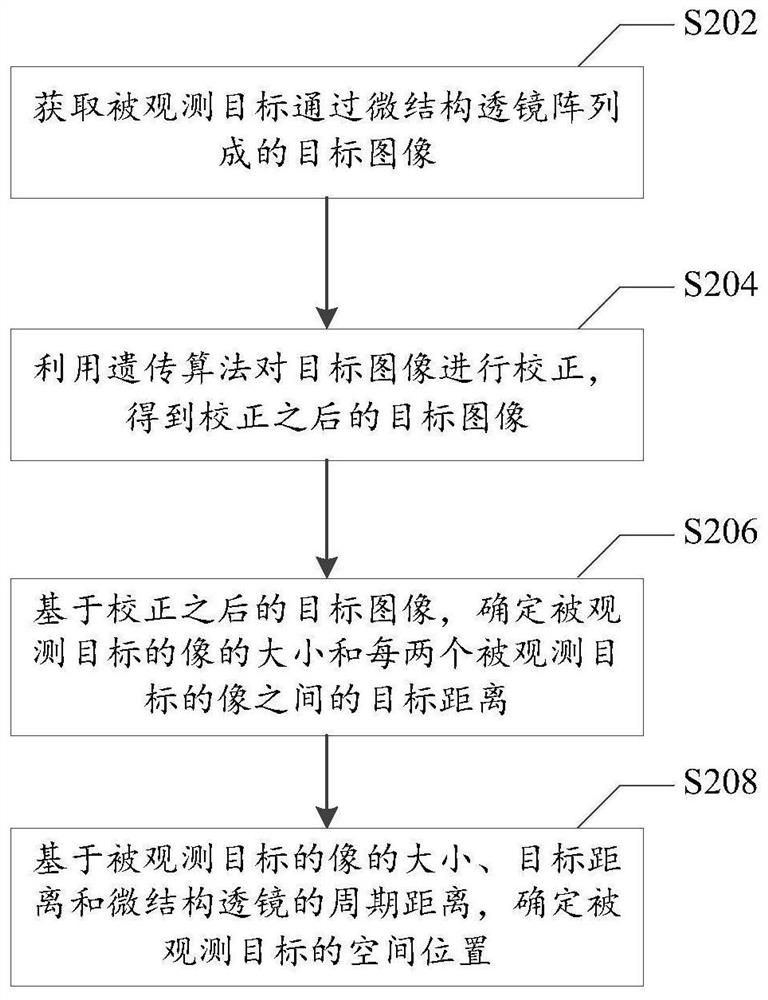

[0031] figure 2 It is a flow chart of a spatial positioning method based on a microstructure lens array according to an embodiment of the present invention, and the method is applied to the microstructure lens array in the first embodiment above. Such as figure 2 As shown, the method specifically includes the following steps:

[0032] Step S202, acquiring the target image formed by the micro-structured lens array of the observed target; the target image includes multiple images of the observed target, and one micro-structured lens corresponds to one image of the observed target. For example, if the micro-lens array includes three micro-lenses, the object image includes images of three observed objects.

[0033] Step S204, using the genetic algorithm to correct the target image to obtain the corrected target image; wherein, the variables to be optimized by the genetic algorithm include: the scaling amount of the target image in the horizontal direction, the translation amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com