Sea sedge product powder spreading device with disassembly-free machine cleaning function and cleaning method thereof

A technology of dusting device and function, applied in the field of dusting device for seaweed products, can solve the problems of low efficiency, lack of convenient cleaning mechanism, complicated operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

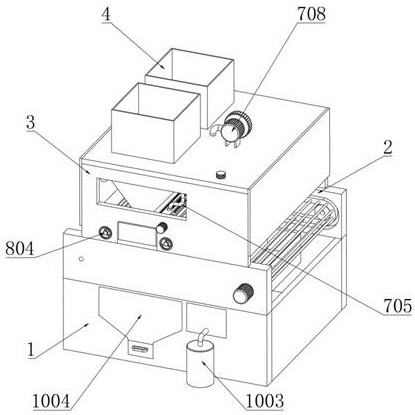

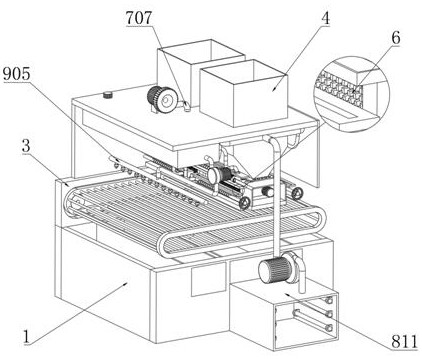

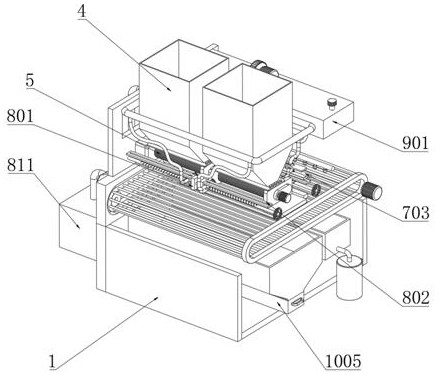

[0061] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a seaweed product dusting device with the function of cleaning without dismantling, including a support base 1, a conveyor belt 2 is fixedly connected to the top of the support base 1, and a sprinkler is fixedly connected to the top of the conveyor belt 2. The powder box 3, the inside top of the powder spreading box 3 corresponds to the top position of the conveyor belt 2, and the seasoning box 4 is symmetrically and fixedly installed, and the bottom of the seasoning box 4 corresponds to the top position of the conveyor belt 2. The bottom of the seasoning box 4 is rotatably connected to the lower trough roller 5, and the bottom of the seasoning box 4 The end corresponds to the side of the trough roller 5 and is connected with a powder sprinkler roller 6. Both sides of the powder spreader box 3 are provided with observation slots, and glass plates are embedded in the observation sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com