Battery pole piece coating adjusting device and adjusting method thereof

A technology for regulating devices and battery pole pieces, which is applied to devices and coatings that apply liquid to the surface, and can solve the problems of uncontrollable adjustment parameters, low precision, and inability to improve products in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manners of the present invention will be described in more detail below with reference to the drawings and examples, so as to better understand the solutions of the present invention and the advantages of various aspects. However, the specific embodiments and examples described below are for the purpose of illustration only, rather than limiting the present invention.

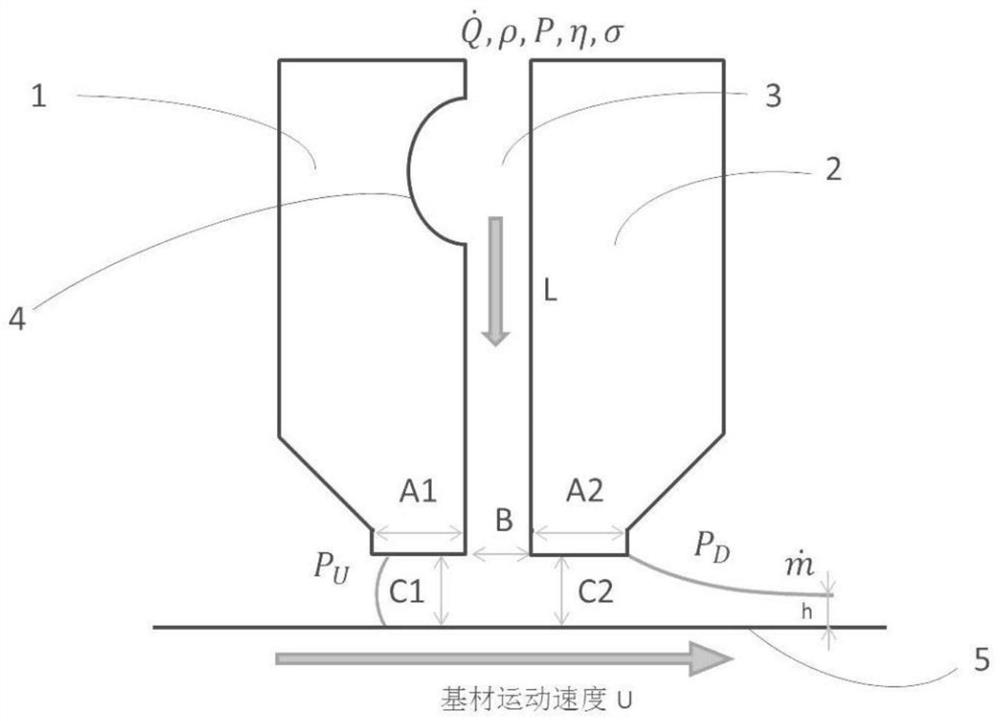

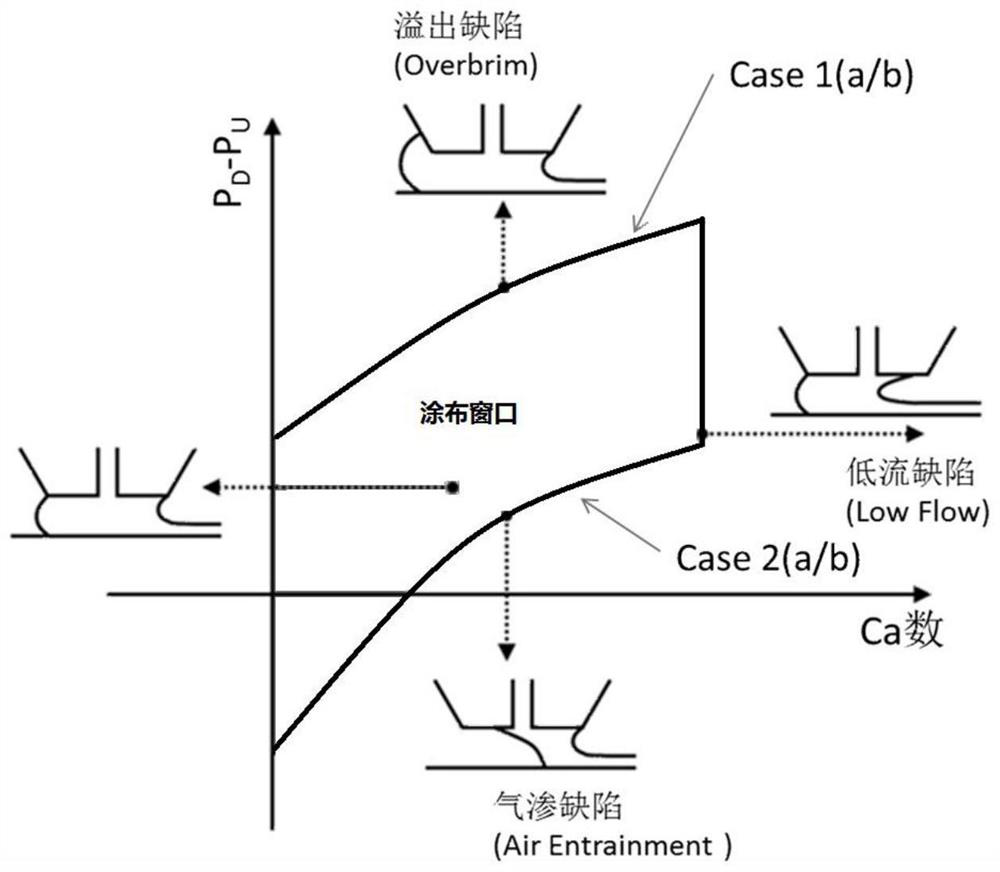

[0045] The inventor found through research that due to the atmospheric pressure P D Constant, the requirements for lip precision, coating spacing and consistency of slurry properties can all be expressed as P 2 The consistency requirement of the pressure at (Fig. 4), such as formula 5:

[0046] Formula 5

[0047]

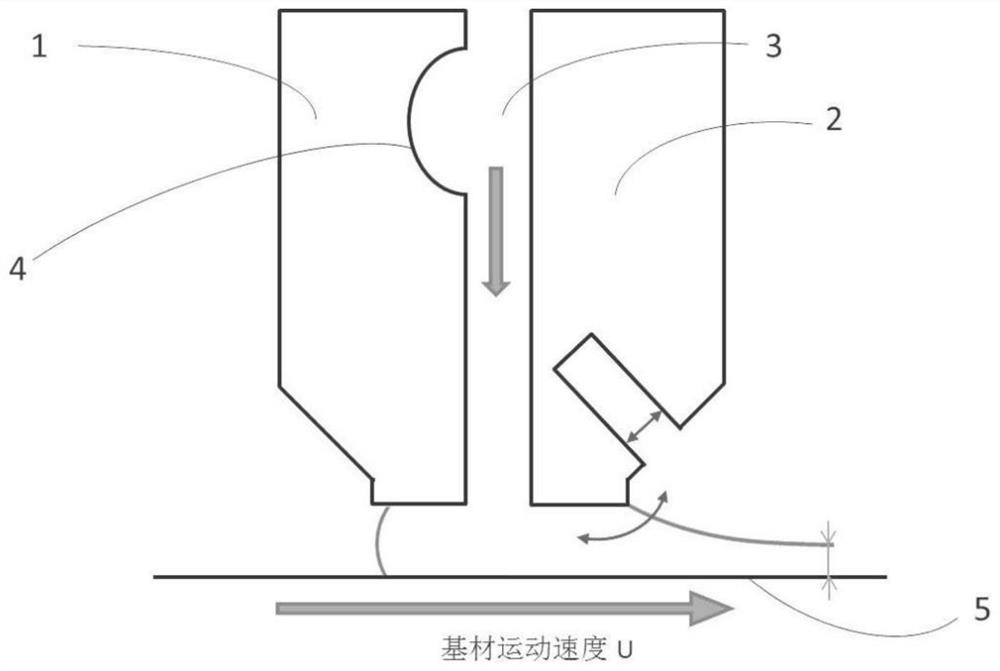

[0048] Therefore, the present invention proposes an adjustment method and corresponding coating adjustment equipment. The pressure measuring element is arranged inside the coating head, and the lateral distribution P of the slurry pressure in the coating head c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com