Mechanical fly ball adjusting jig and method for steam-driving auxiliary water feeding pump

An adjustment method and technology for water supply pumps, applied in the direction of using mechanical devices, mechanical measuring devices, measuring devices, etc., can solve the problems of power generation loss, increased cross-operation, waste and other problems in power plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

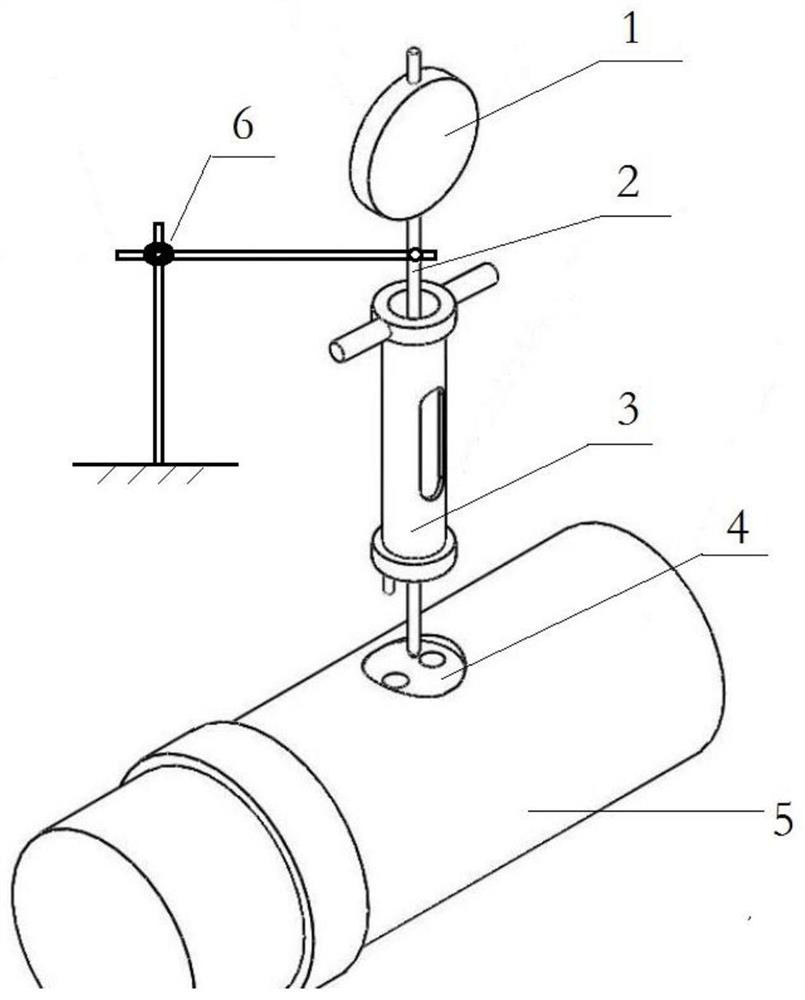

[0044] Such as figure 1 The mechanical flyweight adjustment tool for the pneumatic auxiliary feedwater pump shown includes a dial gauge 1, an extension rod 2, a flyweight adjustment wrench 3, and a magnetic gauge base 6.

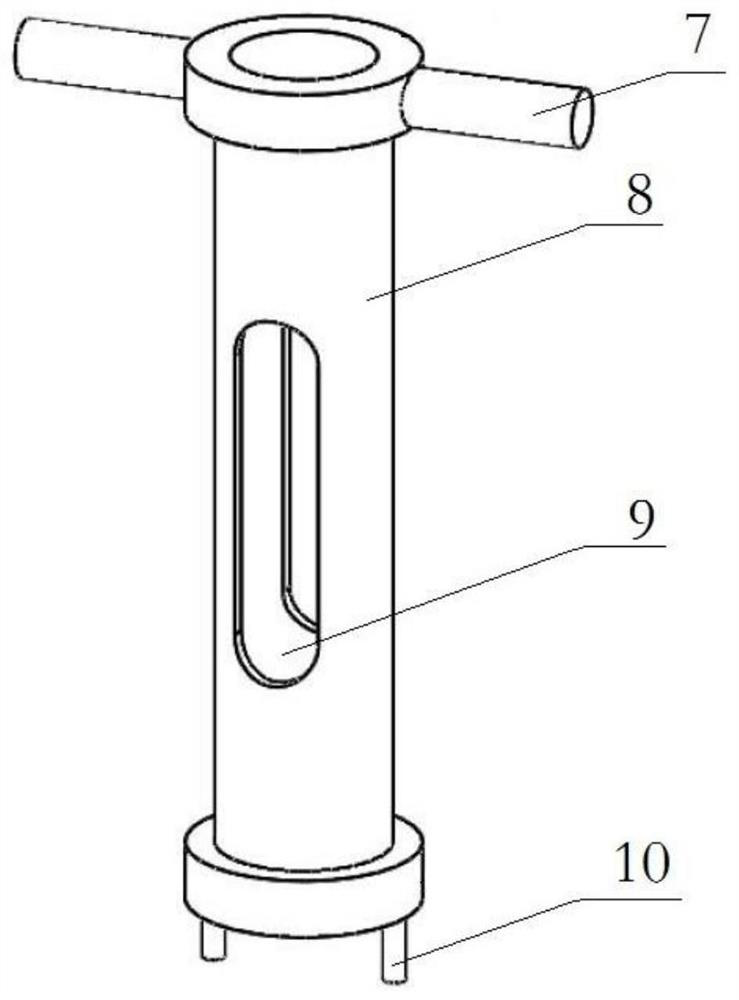

[0045] Such as figure 2 As shown, the middle part of the flyweight adjustment wrench 3 is a sleeve 8, and the sleeve 8 is processed by thick-walled iron pipe fittings.

[0046] Drilling and tapping in the radial 180° symmetrical direction on the upper part of the sleeve 8 is used to fix a pair of handles 7; at the bottom of the sleeve 8, drilling and tapping at positions corresponding to the handle 7 up and down are used to install two handles. A grab bar 10; two observation holes 9 are processed at a symmetrical 180° position on the middle side wall of the casing 8, and the central axis of the two observation ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com