Corresponding device for actual position of unmanned crown block and absolute positions of saddles and method

A technology of actual position and absolute position, which is used in measurement devices, surveying and navigation, transportation and packaging, etc. It can solve problems such as affecting the precise operation of unmanned cranes and large errors in saddle position calibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the examples.

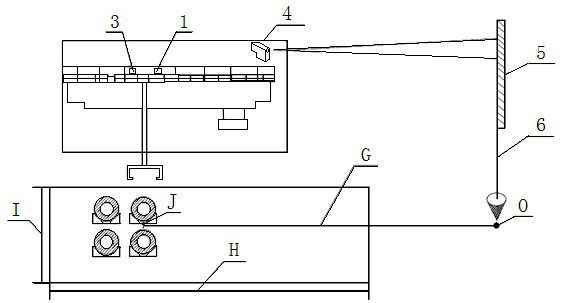

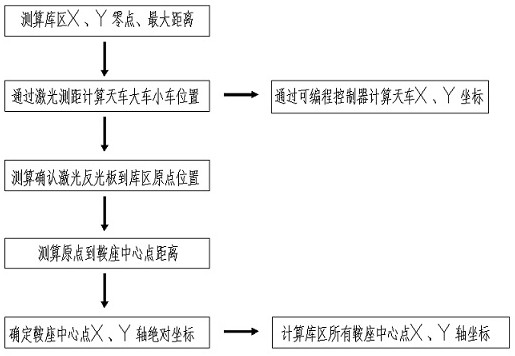

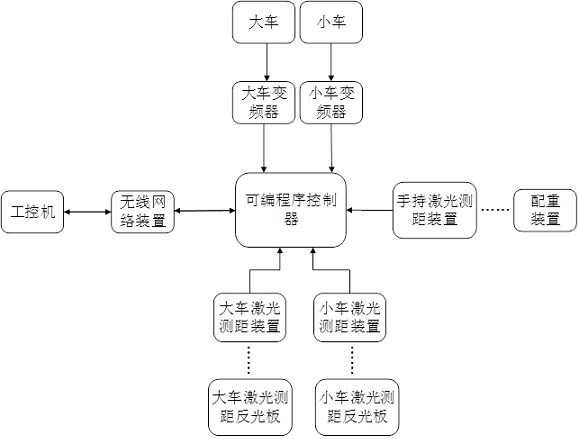

[0023] The invention discloses a corresponding device for the actual position of the unmanned crane and the absolute position of the saddle, see figure 1 and image 3 , applied to the carts and trolleys of the unmanned crane, including the industrial computer installed in the PLC room of the unmanned crane, the wireless network device 1 connected to the industrial computer, the programmable controller 3 connected to the wireless network device 1, The large vehicle laser ranging device 4 and the small vehicle laser ranging device connected to the programmable controller 3, the large vehicle laser ranging reflector 5 corresponding to the large vehicle laser ranging device 4, and the trolley corresponding to the small vehicle laser ranging device The laser ranging reflector, the counterweight device 6 installed under the laser ranging reflector 5 of the cart through the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com