Numerical-control machine tool servo adjustment method based on TCP/IP protocol

A technology of CNC machine tools and IP protocol, which is applied in the field of CNC machine tools, can solve the problems that servo data cannot be displayed in real time and intuitively, and the operation is inconvenient, and achieve the effect of convenient operation and accurate calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

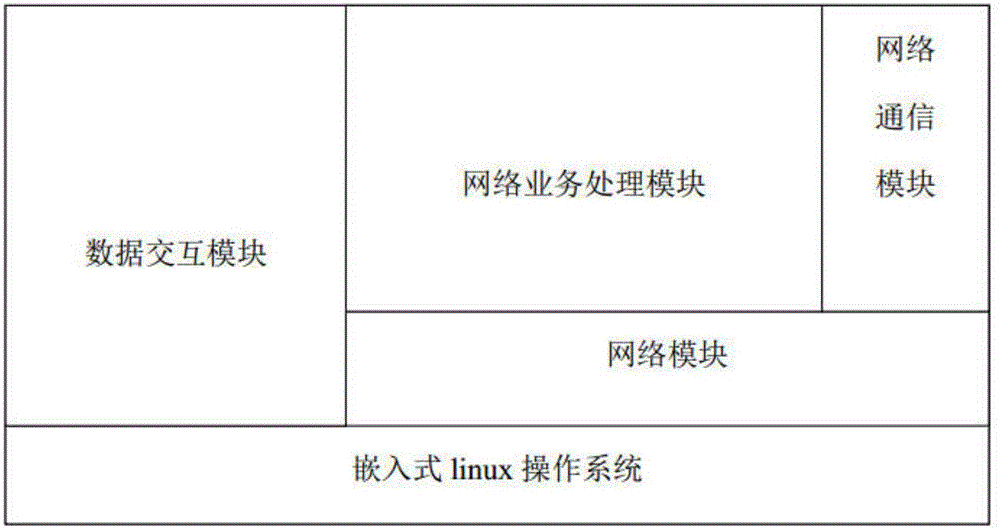

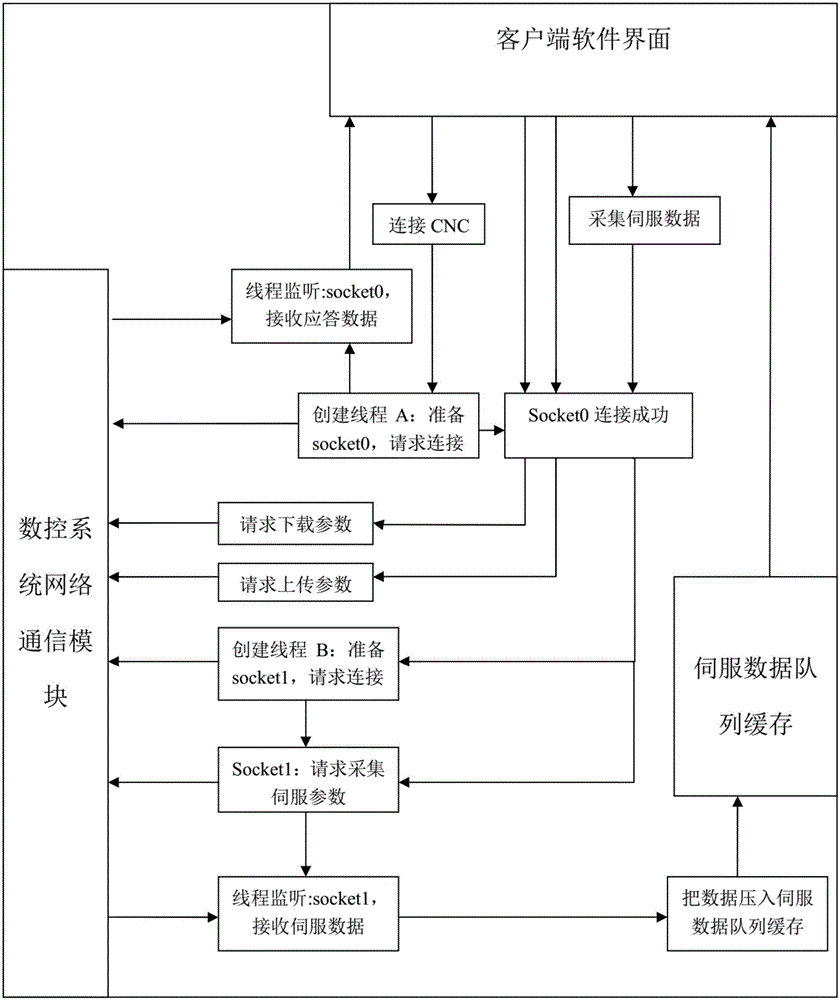

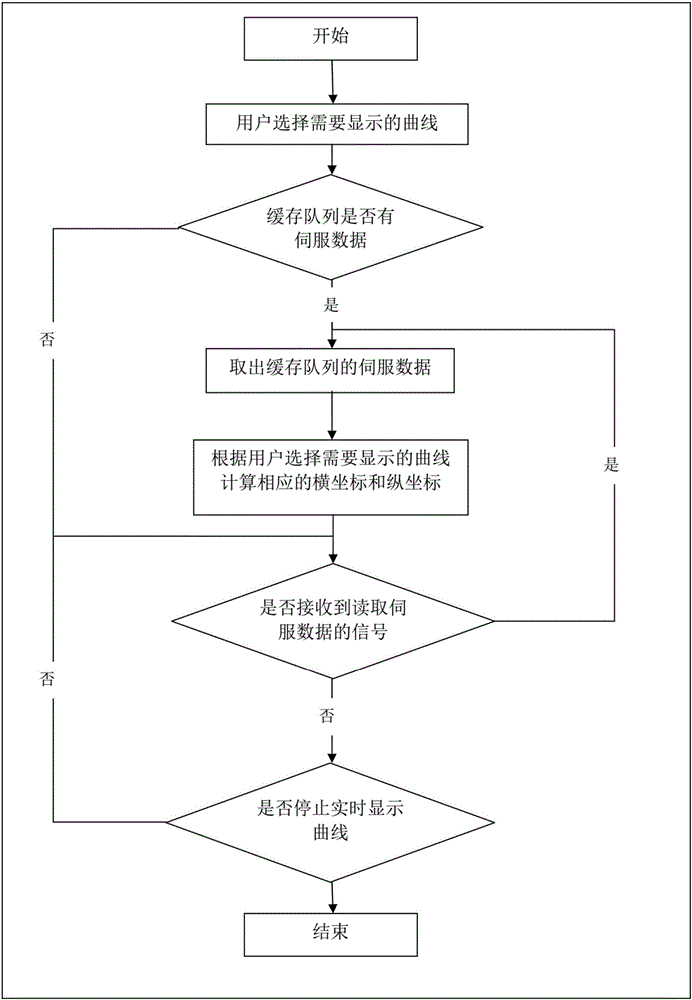

[0045] Such as figure 1 As shown, based on the embedded linux operating system, realizes the network server module of the numerical control system of TCP / IP. The network server is mainly composed of a network communication module and a network business processing module. The network communication module is designed based on the select model of linux API. It is oriented to multiple clients and multiple connections. It is responsible for accepting and managing client connections, receiving data packets, and sending data packets. After the numerical control system starts, start the network communication thread, initialize the socket that the server responds to the connection request, and add the socket to the monitoring set of the select model. When a client requests a connection, get a new socket to communicate with the client, and continue to add the socket to the listener collection of the select model. The server uses a connection protocol mode similar to FTP, which is divi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com