Molecular sieve oxygen generation mechanism of portable oxygen generator

A technology of molecular sieve and oxygen generator, applied in the field of mechanical structure, can solve the problems of large structure volume, complex internal structure, heavy weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

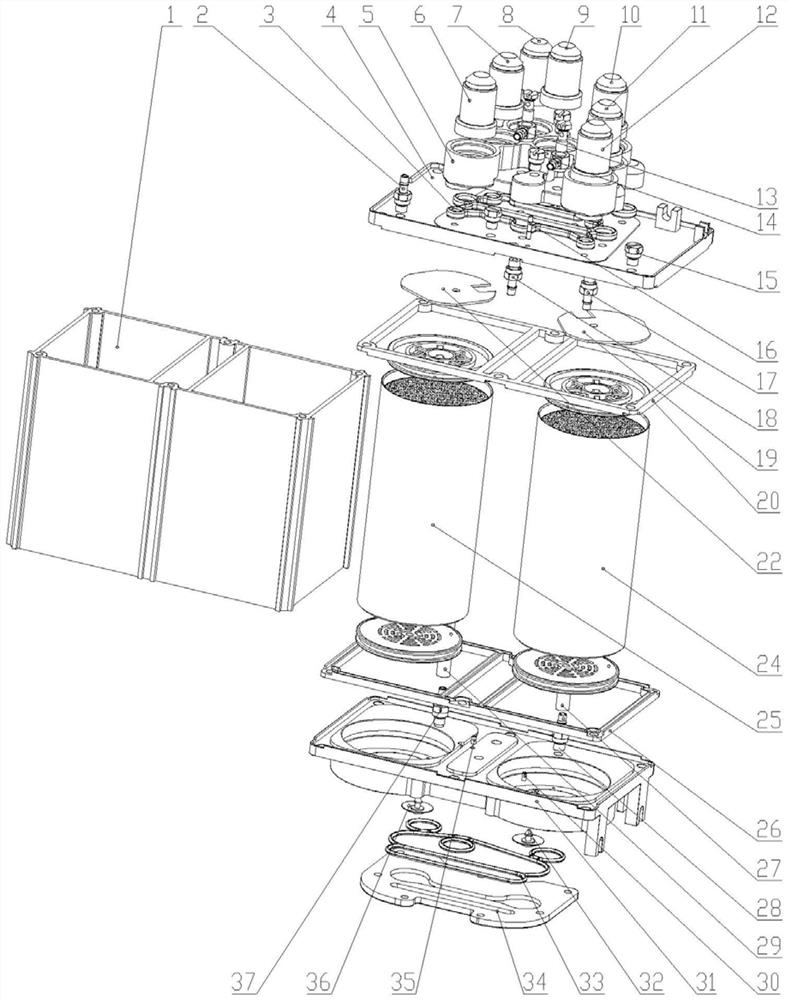

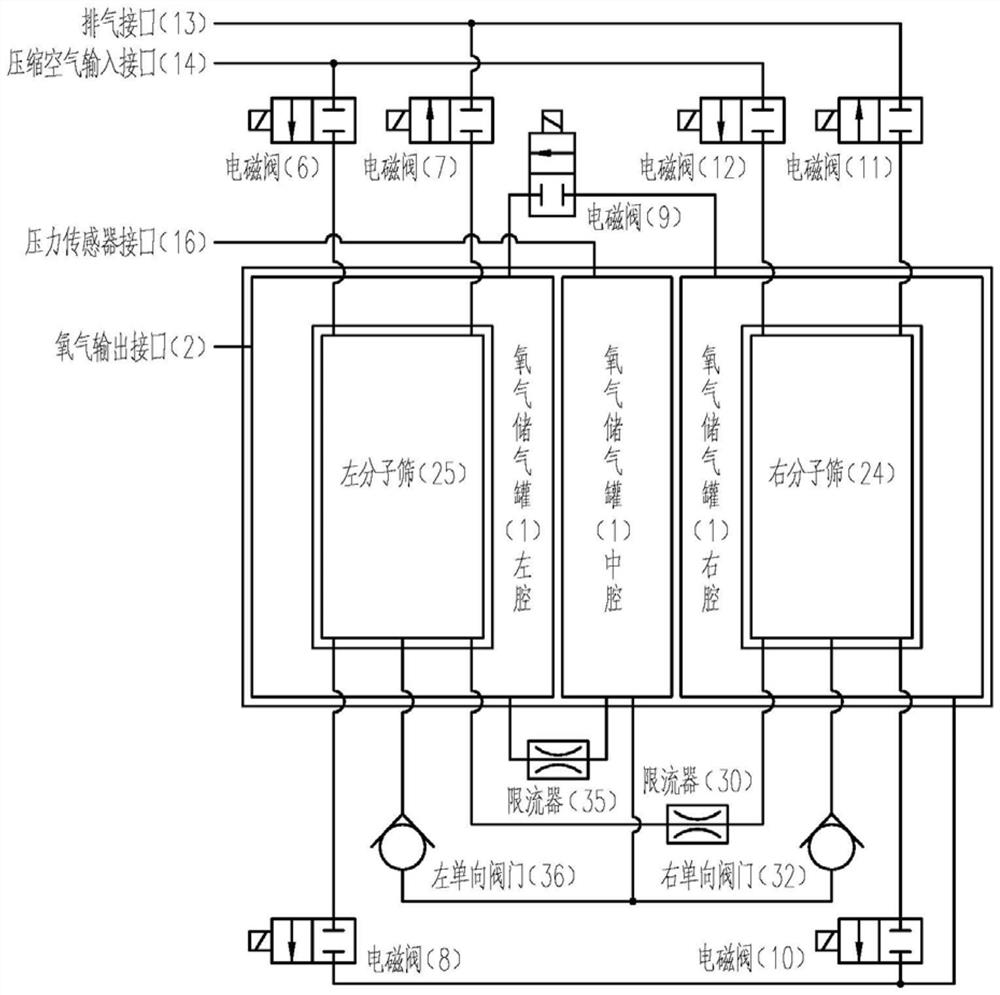

[0030] see figure 1 As shown, the main structural parts of the molecular sieve oxygen generating mechanism of a portable oxygen generator shown in this embodiment are made of aluminum-magnesium alloy, and the surface is anodized. Contains an oxygen storage tank 1, a right molecular sieve tank 24, a left molecular sieve tank 25, a solenoid valve seat 5 and a lower gas path cover 34.

[0031] The inside of the oxygen storage tank 1 is divided into a left cavity, a middle cavity and a right cavity, the left molecular sieve tank 25 is placed in the left cavity, and the right molecular sieve tank 24 is placed in the right cavity.

[0032] The top of the oxygen gas storage tank 1 has an oxygen gas storage tank upper cover 4, and the electromagnetic valve seat 5 is installed on the oxygen gas storage tank upper cover 4, and the electromagnetic valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com