Odor-resistant and flow-controllable sewage treatment equipment for paddy field fish culture

A kind of sewage treatment equipment and anti-odor technology, applied in water/sewage treatment, multi-stage water/sewage treatment, light water/sewage treatment, etc., can solve problems that affect normal breeding, easy to produce peculiar smell, and cannot be treated in sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

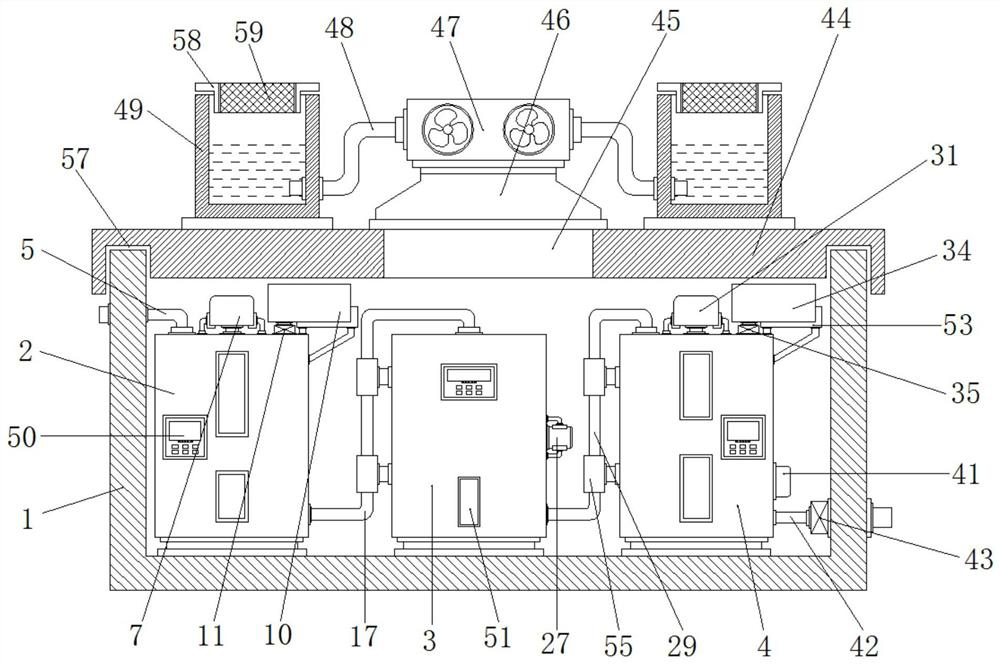

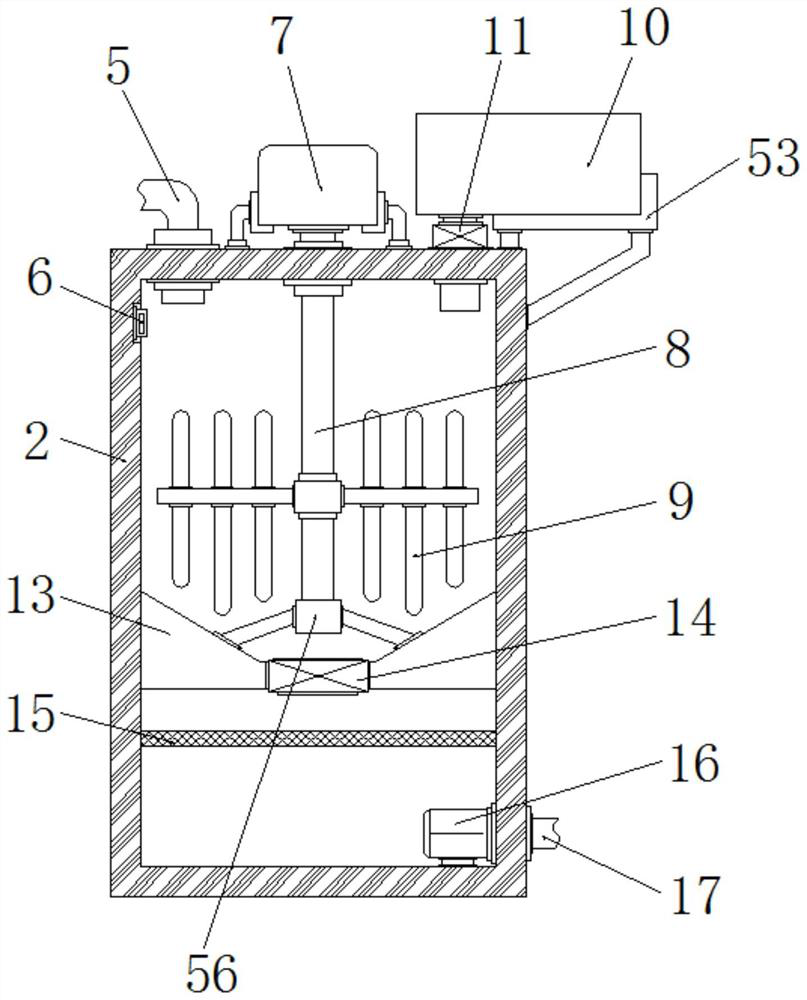

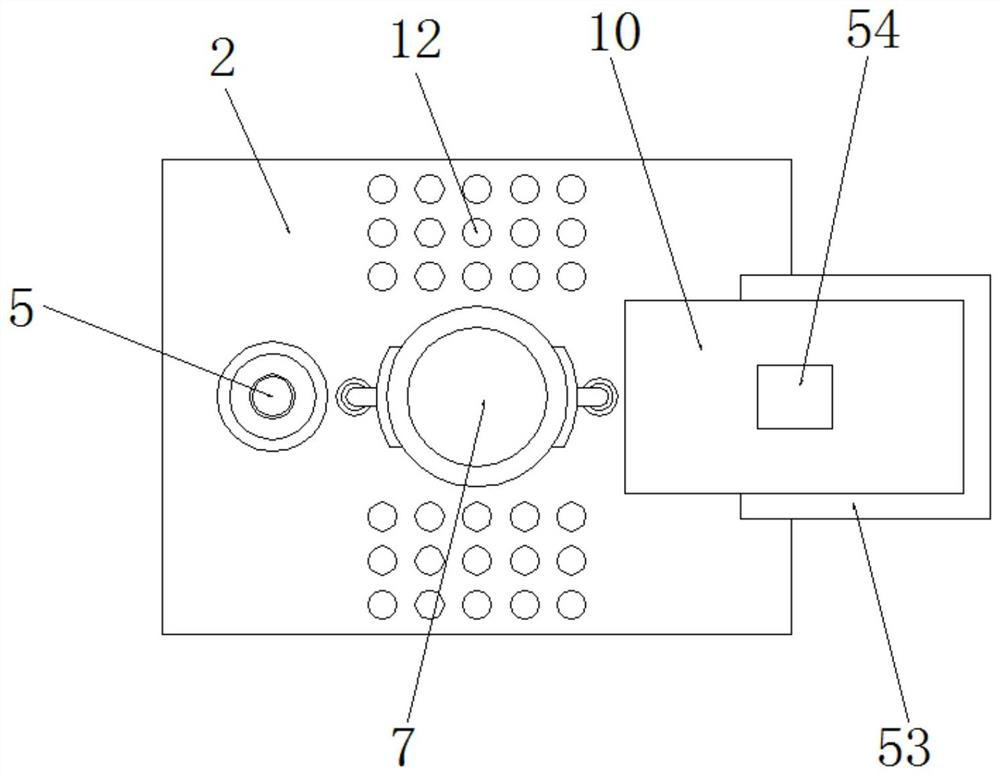

[0034] Embodiment one, such as Figure 1-9As shown, an anti-odor and flow-controllable sewage treatment equipment for paddy field fish farming according to an embodiment of the present invention includes a box body 1, and a sedimentation bin 2, a filter bin 3, and a purification bin are installed inside the box body 1. 4. A water inlet pipe 5 is installed on the top side of the sedimentation bin 2, and the end of the water inlet pipe 5 away from the sedimentation bin 2 penetrates and extends to the top of the side of the box body 1, and the sedimentation bin 2 A water level sensor-6 is installed on the top of one side of the interior, a motor-7 is installed on the top of the sedimentation bin 2 and one side of the water inlet pipe 5, and a rotating rod-8 is installed on the bottom of the motor-7. And the bottom end of the rotating rod-8 runs through and extends to the inside of the sedimentation bin 2, the outer side of the rotating rod-8 is symmetrically equipped with a stirr...

Embodiment 2

[0035] Embodiment two, such as figure 1 As shown, a controller 50 is installed on the outside of the sedimentation bin 2, the filter bin 3 and the purification bin 4, the model of the controller 50 is KY12S, and the controller 50 is equipped with The display model is MAM-26A; through the controller 50, people can better control it when using it, so as to better meet people's use needs.

Embodiment 3

[0036] Embodiment three, such as figure 1 , 9 As shown, the outer sides of the sedimentation bin 2, the filter bin 3 and the purification bin 4 are all embedded with a transparent glass plate 51; the outer side of the box body 1 is embedded with a transparent glass plate Plate two 52: through the interaction between the first transparent glass plate 51 and the second transparent glass plate 52, it is convenient for people to check when using, so as to better meet people's use needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com