Construction method of biting pile

A construction method and technology of occlusal piles, which are applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of easy shrinkage, reduction of pile body bending moment, pile breakage, etc., and achieve strong horizontal resistance, Avoid environmental pollution and ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention will be clearly and completely described below.

[0025] A construction method of an occlusal pile, comprising the following steps:

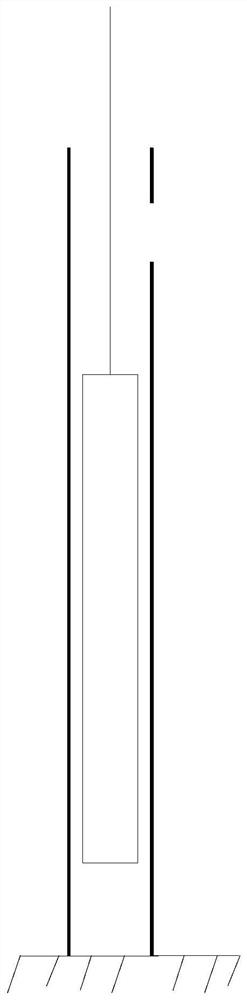

[0026] Step one, such as figure 1 As shown, the pile position is determined by scribing, the pile driver is erected above the pile location, and the inner hammer and the outer pipe with a circular cross section are connected above the pile driver.

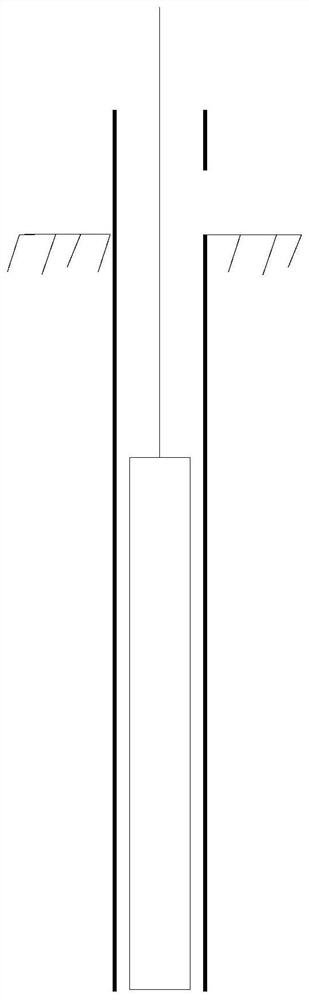

[0027] Step 2: If figure 2 As shown, align the inner hammer at the center of the pile position, start the pile driver, the inner hammer impacts the soil and the outer pipe wall, and the inner hammer and the outer pipe sink alternately to the design elevation to form the pile hole;

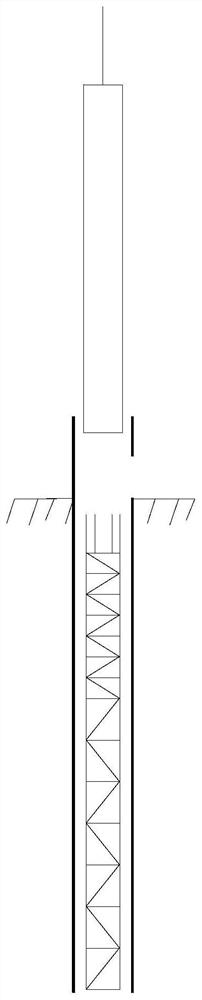

[0028] Step 3: If image 3 As shown, fix the outer tube, pull out the inner hammer, and place the reinforcement cage inside the outer tube;

[0029] Step 4: If Figure 4 As shown, add the stirred concrete at the hole of the outer tube or the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com