Steam turbine rotor and steam turbine

A technology of steam turbines and rotors, which is applied in the directions of machines/engines, mechanical equipment, engine components, etc., and can solve problems such as scattering of implanted fins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

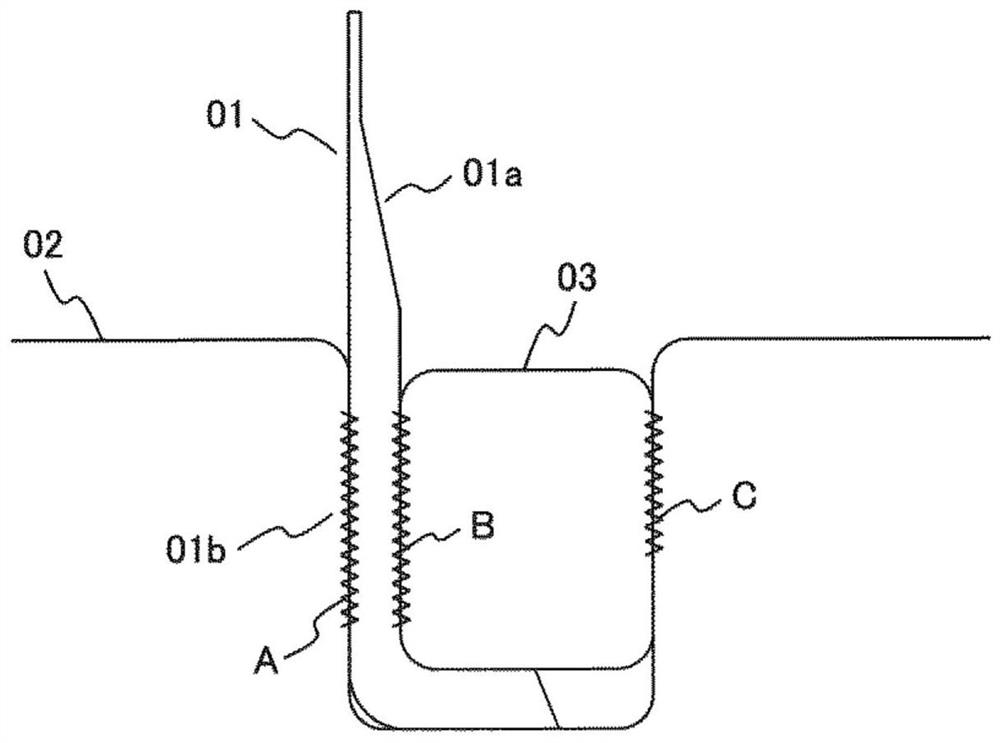

[0022] figure 1 It is a schematic diagram explaining the implanted fin which does not have the wedge-shaped groove described in this Example.

[0023] In order to prevent steam (operating fluid) from flowing from the gap (interval) formed between the inner peripheral surface (not shown) of the stationary body and the outer peripheral surface of the rotating body (steam turbine rotor) (hereinafter referred to as "rotor") 02, the steam turbine Leakage, set the sealing fins.

[0024] In particular, there are two types of seal fins provided on the rotor side: chipped fins formed by processing the rotor and implanted fins fixed to grooves formed in the rotor.

[0025] The sealing fins described in this embodiment are implanted fins. The implant fin 01 has a replaceable structure, so when the tip is damaged, it can be replaced with a new implant fin 01 and the sealing performance can be restored.

[0026] The implanted fin 01 described in this embodiment is a fin made by bending ...

Embodiment 2

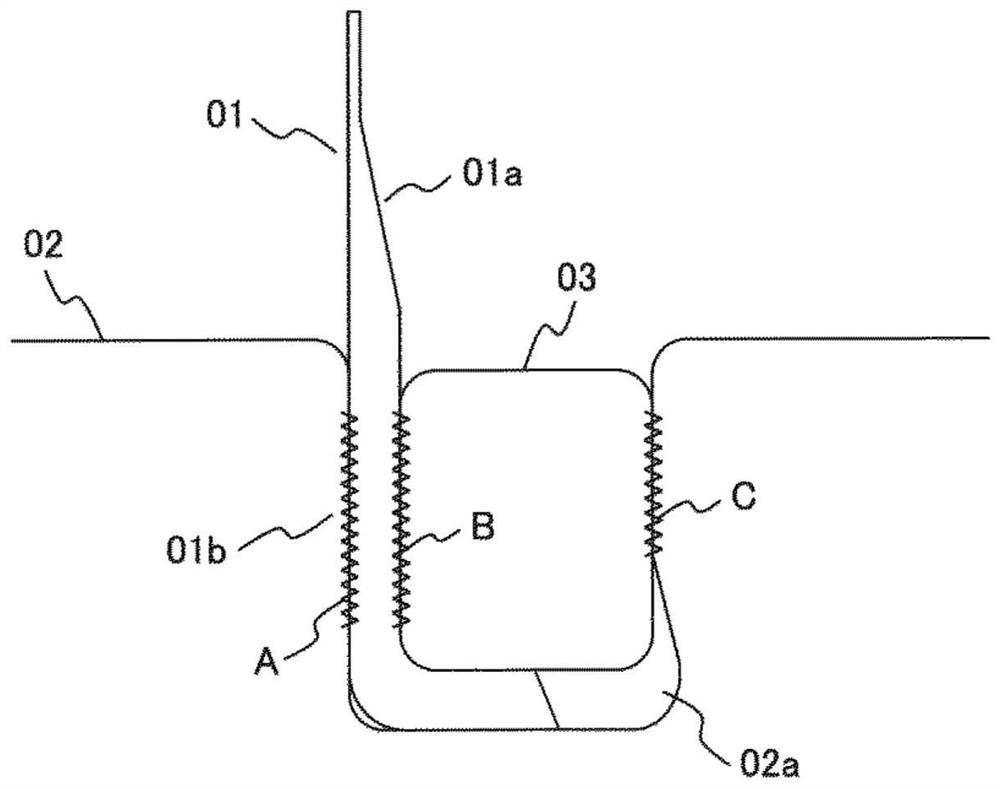

[0050] figure 2 It is a schematic diagram explaining the implanted fin having a wedge-shaped groove described in this embodiment, and is a cross-sectional view.

[0051] This embodiment differs from the first embodiment in that the fixing groove 04 has a wedge-shaped groove 02a. That is, the rotor 02 described in this embodiment is different from the first embodiment in that the fixing groove 04 has the wedge-shaped groove 02a.

[0052] Thus, in this embodiment, the wedge-shaped groove 02a is provided in the fixing groove 04, and the locking strip 03 enters the wedge-shaped groove 02a, whereby the pull-out strength of the implanted fin 01 can be further improved.

Embodiment 3

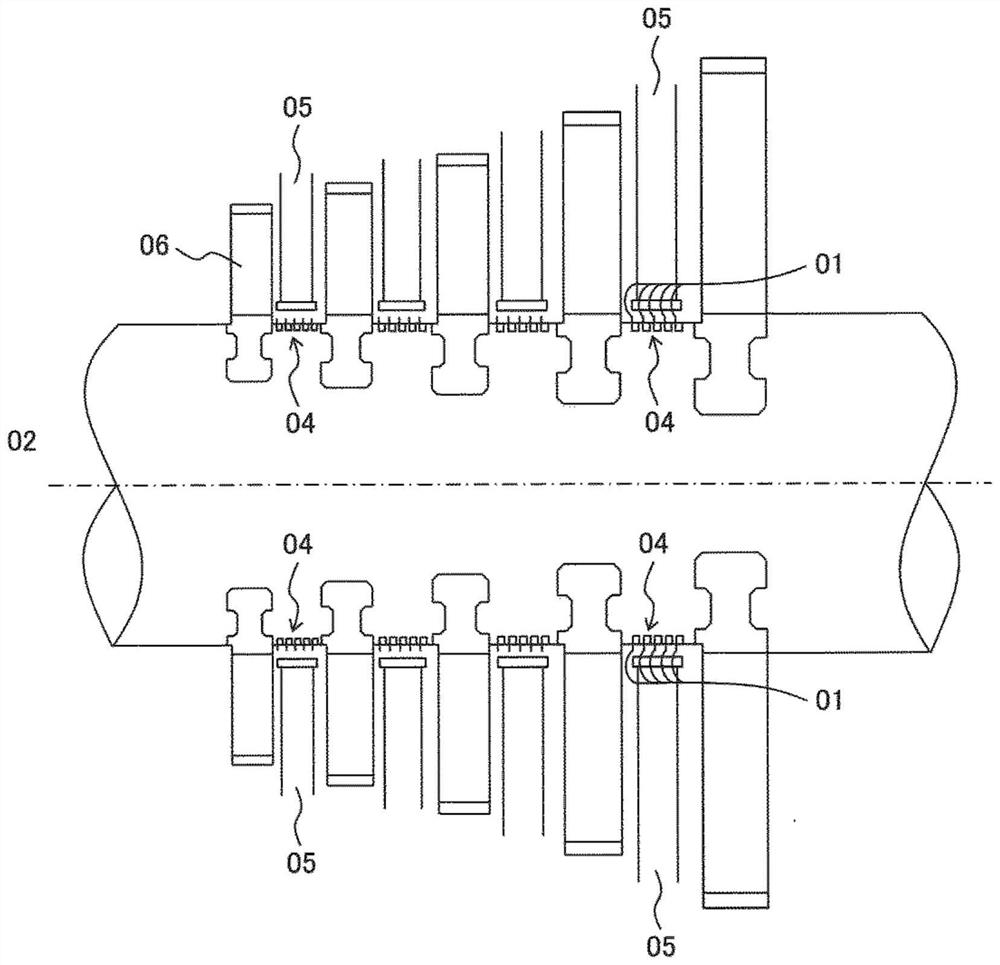

[0054] image 3 It is a schematic diagram explaining the steam turbine described in this embodiment.

[0055] The steam turbine described in this embodiment has a rotor 02 , moving blades 06 provided on the rotor 02 , stationary blades 05 , and implanted seal fin portions 04 .

[0056] The stator blades 05 expand the steam to impart velocity energy to the steam, change the flow direction of the steam, and generate momentum in the rotation direction.

[0057] The implanted seal fin 01 is provided on the implanted seal fin part 04 , and the implanted seal fin 01 is provided so that steam does not leak from between the tip of the stator blade 05 and the rotor 02 .

[0058] The moving blades 06 are arranged on the rotor 02 to transform the thermal energy retained by the steam into the rotational energy of the rotor 02 .

[0059] By providing the implanted fins 01 described in the first or second embodiment on the rotor 02 of such a steam turbine, a steam turbine with improved re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com