Reciprocating compressor energy efficiency analysis system based on P-V diagram test

A technology for analyzing systems and compressors, applied in the field of compressors, which can solve problems such as lack of on-site installation conditions and safety regulations not allowed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

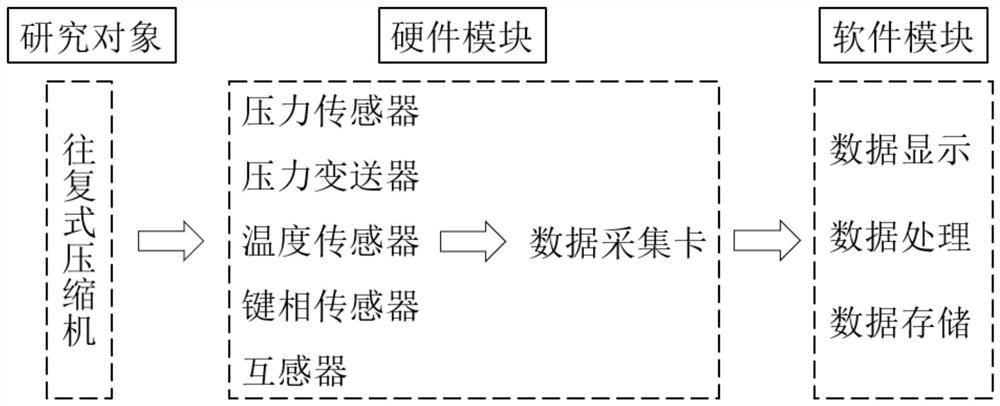

[0057] Such as figure 1 As shown, a kind of reciprocating compressor energy efficiency analysis system based on the p-V diagram test of the present invention comprises:

[0058] Hardware module: Obtain the parameters necessary for energy efficiency analysis of reciprocating compressors, including inlet and outlet pressures, inlet and outlet temperatures, cylinder pressures, key phase signals, motor voltage and motor current;

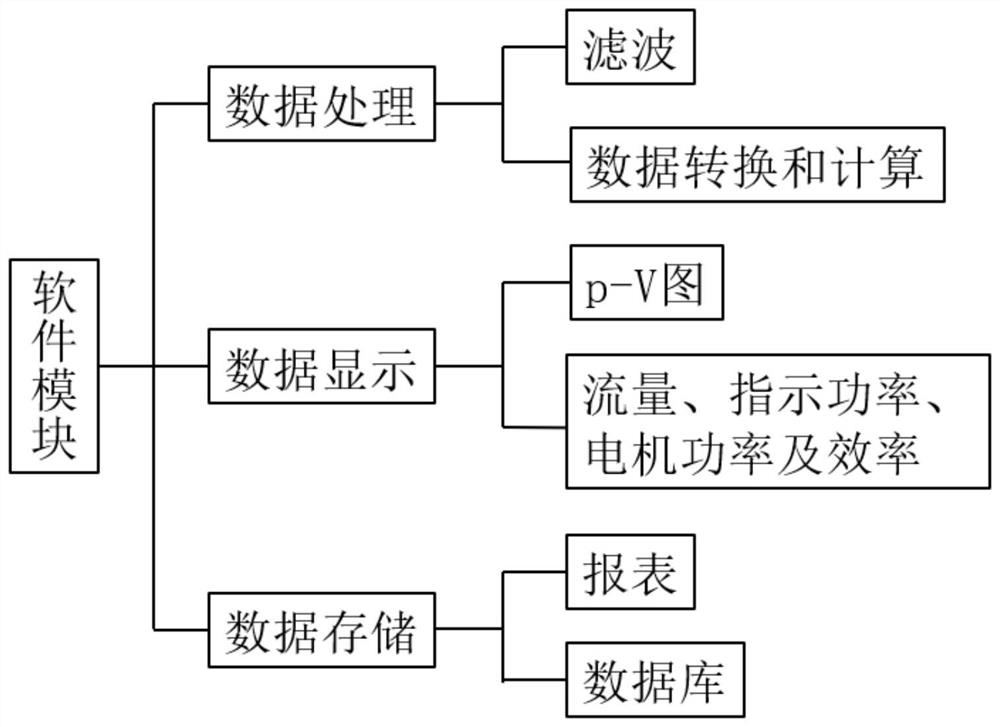

[0059] Software module: convert and process the parameter signals acquired by the hardware module, and output the p-V diagram, flow rate, indicated power, Motor power and efficiency.

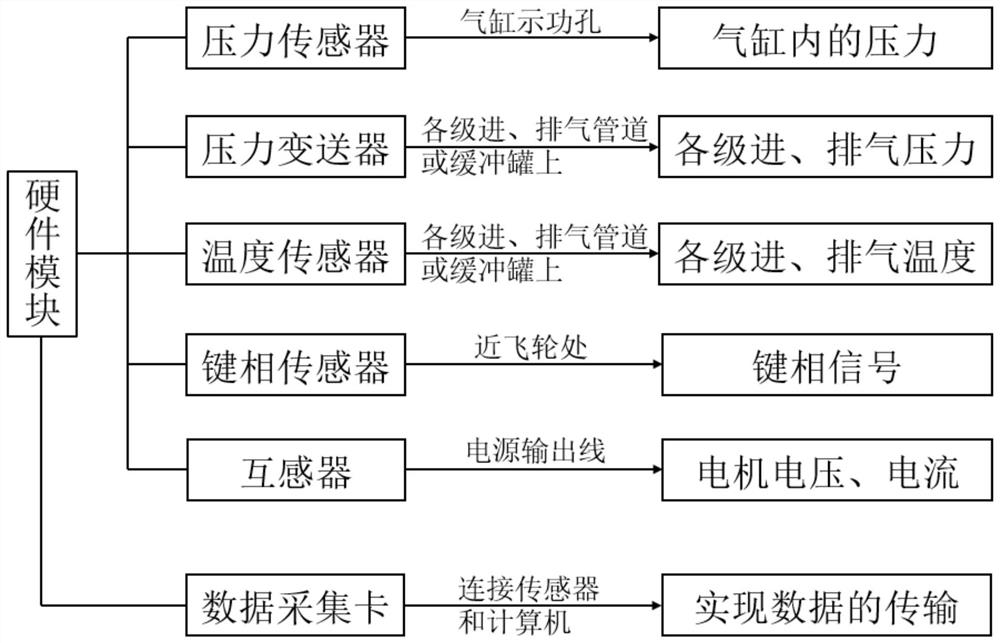

[0060] Such as figure 2 As shown, the hardware modules include:

[0061] Pressure sensor: Installed on the indicator holes of the cylinders at all levels of the reciprocating compressor to collect the pressure values in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com