No-tillage and shallow-turning seeding device for crops

A seeding device and crop technology, applied in the direction of sowing seeders, seeder parts, fertilizers and seeding equipment, etc., can solve problems such as burning seedlings, affecting seedling emergence rate, and high field soil water loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

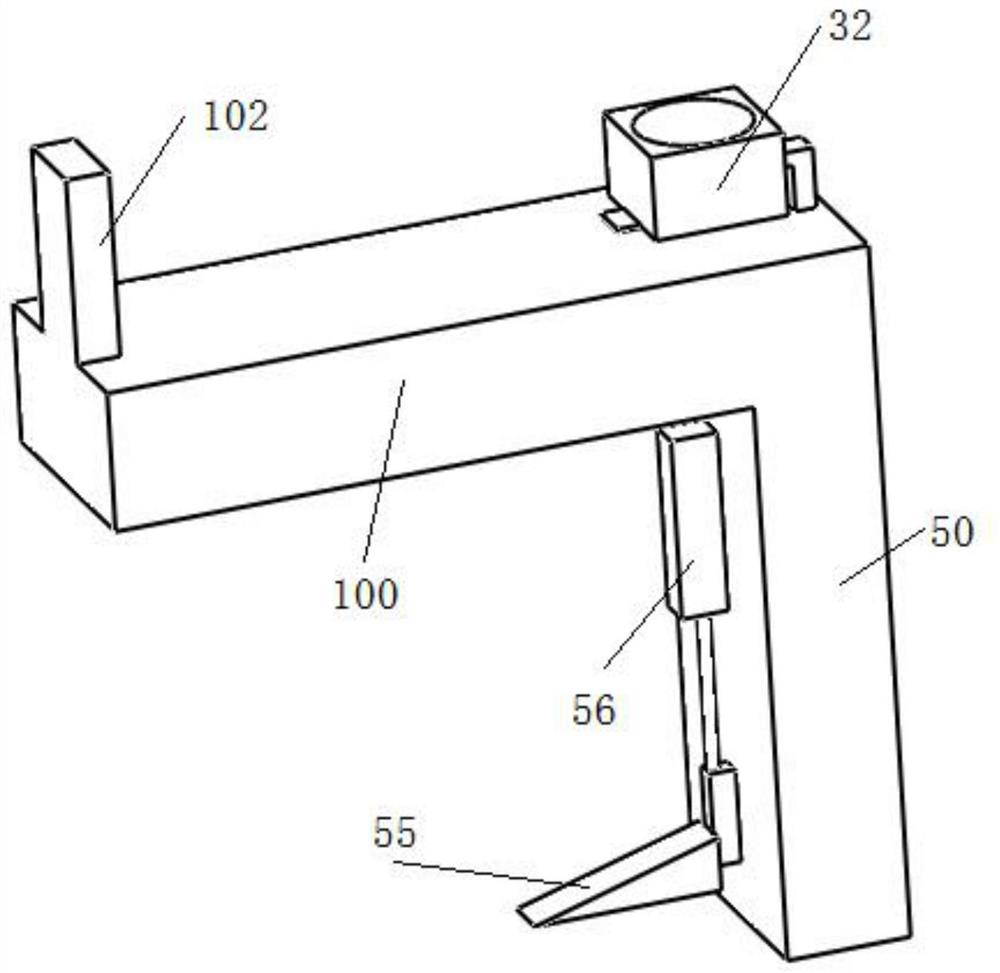

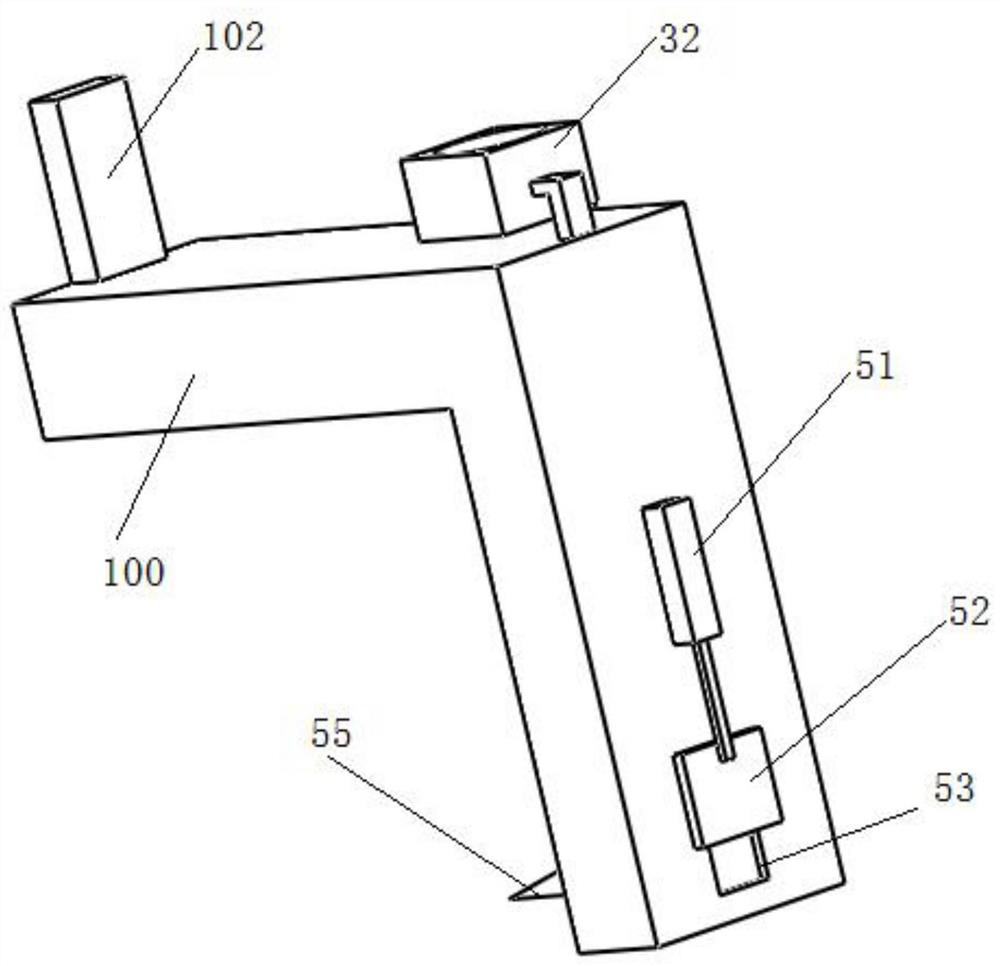

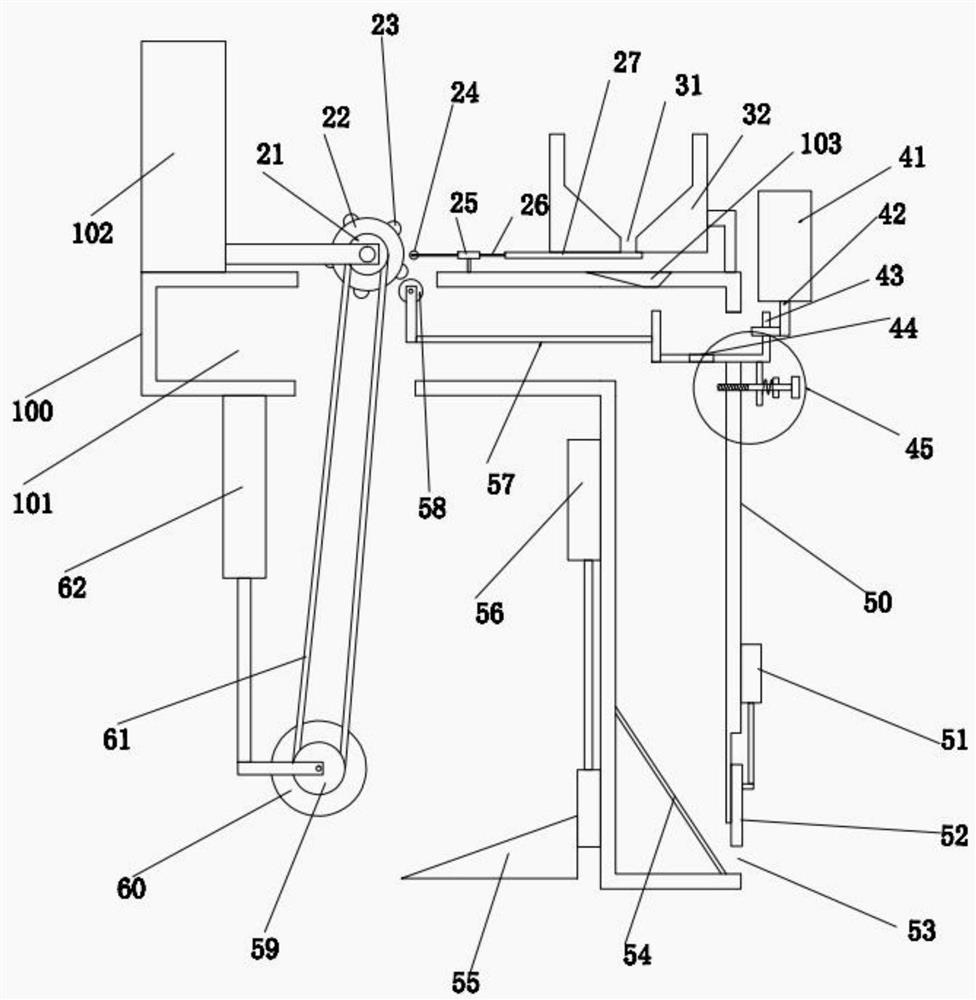

[0024] see Figure 1-5 , in an embodiment of the present invention, a no-tillage shallow plowing planting device for crops includes a fixed box 100 and a feeding inner cavity 101 arranged inside it. Mounting plate 102, the lower right side of the fixed box 100 is provided with a lower material cylinder 50, the inside of the lower material cylinder 50 communicates with the inside of the feeding inner chamber 101, and the lower right side of the lower material cylinder 50 is provided with a discharge port 53 , the discharge port 53 is equipped with a discharge baffle 52, the upper end of the discharge baffle 52 is connected to the first telescopic rod 51 for driving it to move up and down to realize the discharge, and the lower barrel near the discharge port 53 50 is provided with a guide plate 54 for guiding the discharge of materials. The upper end of the fixed box 100 where the lower material barrel 50 is located is provided with a seed box 32, and the middle position of the ...

Embodiment 2

[0027] see Figure 1-5 , the fixed box 100 is also provided with left and right pushers for driving the movable sealing plate 27 to open or close intermittently, the left and right pushers include a sliding rod 26 connected to the left end of the movable sealing plate 27, and the outer side of the sliding rod 26 The sliding sleeve is provided with a fixed sleeve 25 connected to the upper end surface of the fixed box 100. The fixed sleeve 25 and the sliding rod 26 are connected by a reciprocating spring. The left end of the fixed sleeve 25 is provided with a first pressing wheel 24. The upper and lower ends of the fixed box 100 where the pressure roller 24 is located are perforated, and a rotating disc 22 is arranged above the perforation. A first pulley 21 is provided, and the first pulley 21 is connected to the second pulley 59 on the lower side through a stretchable elastic transmission belt 61. The side of the second pulley 59 is coaxially provided with a running wheel 60, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com