Automatic cavity displacement control system and exhaust heat dissipation system

A heat dissipation system and air discharge technology, which is applied to steam cooking utensils, cooking utensils, household appliances, etc., can solve the problems of inability to adjust and control the exhaust volume, complex structure, and inability to adjust the aperture of the exhaust hole.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

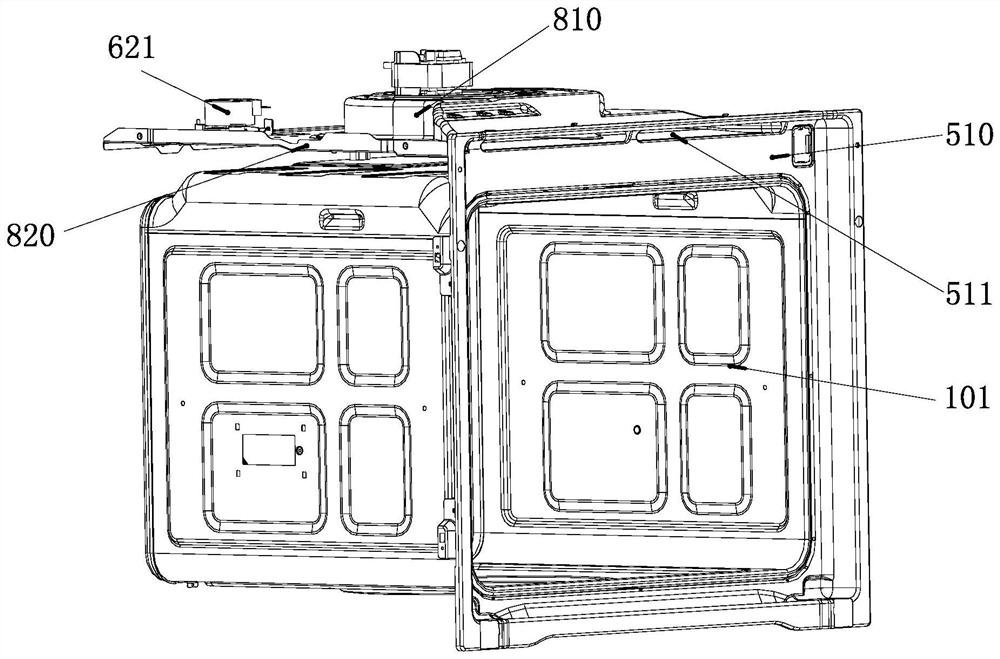

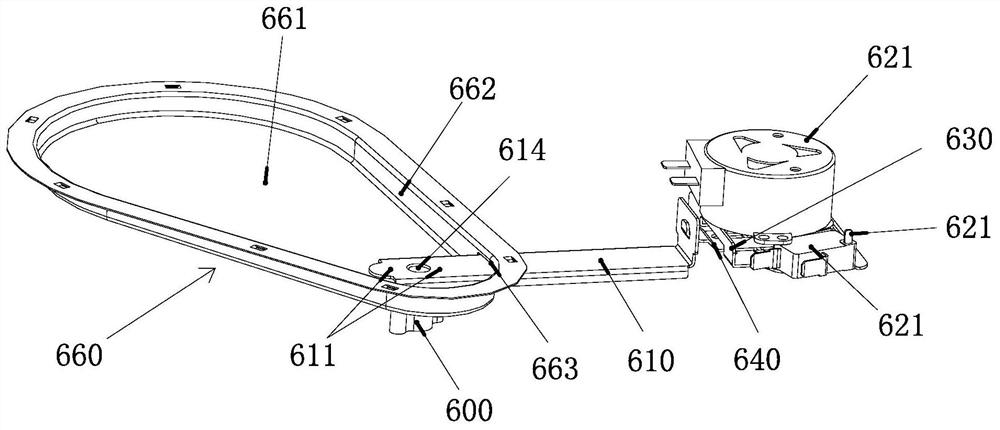

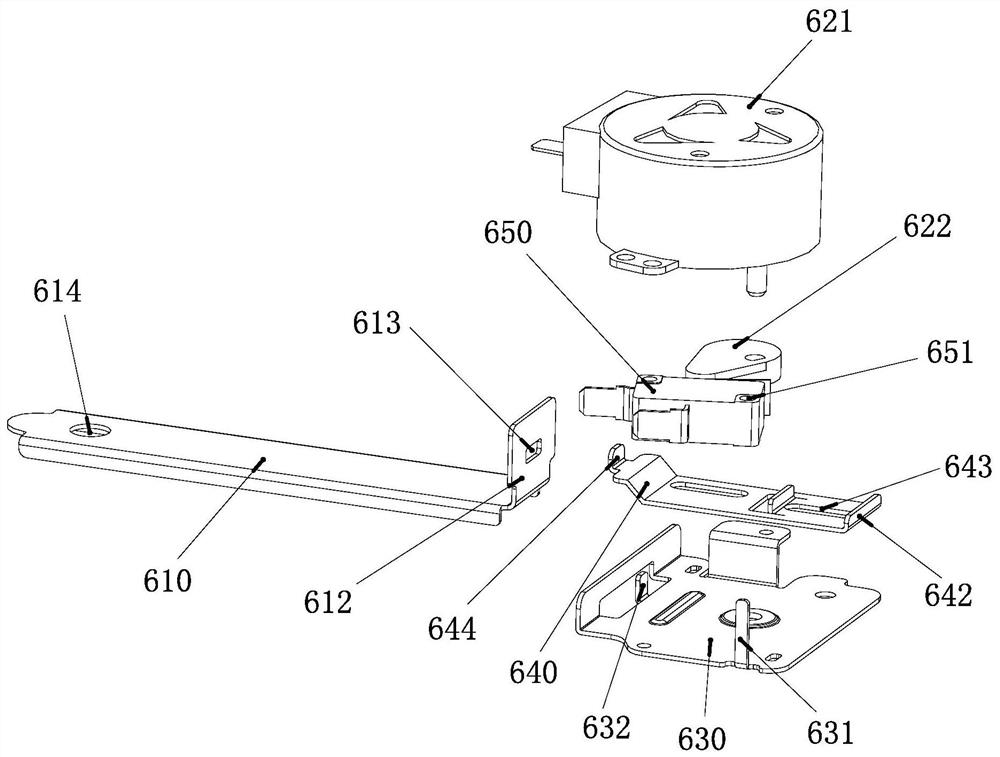

[0042] The present invention is described in detail below in conjunction with accompanying drawing, see Figure 1-Figure 14 :

[0043] A cavity automatic control exhaust volume system, such as figure 2As shown, it includes an exhaust tube 600 installed on the steam oven box (the middle part of the exhaust tube 600 is provided with an exhaust hole 601 for exhausting, and the two sides of the exhaust hole 601 are provided with the exhaust tube that can be installed on the box body. The installation hole position 602 on the upper part), the adjustment plate 610 arranged above the exhaust cylinder 600, and the driving device that connects the adjustment plate 610 and drives the adjustment plate 610 to move, the adjustment plate 610 controls the exhaust during the movement. The opening and closing of the hole 601; the adjustment plate 610 is provided with a covering part 611, and the covering part 611 moves above the exhaust hole 601 under the drive of the driving device, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com