New generation CIR automatic test fixture and implementation method thereof

An automatic test, a new generation of technology, used in manufacturing tools, workpiece holding devices, transmission systems, etc., can solve the problems of many test items, infrequently used, no need to meet fast field tests, etc., to improve the test speed, meet the The effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to understand the present invention more clearly, the following detailed description is given in conjunction with the accompanying drawings and embodiments.

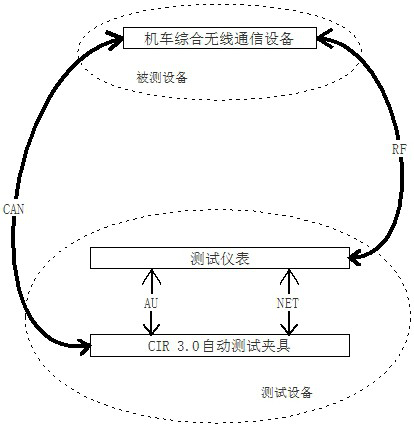

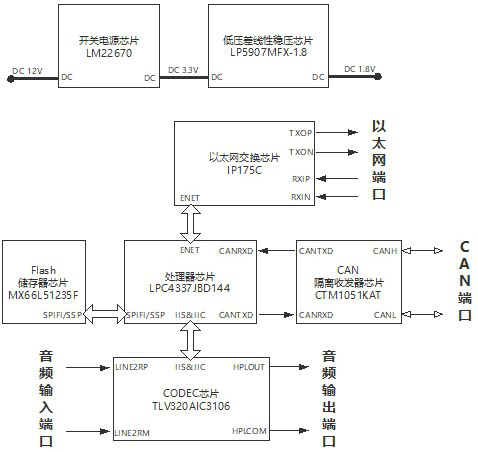

[0011] Such as figure 1 with figure 2 As shown, a CIR3.0 automatic test fixture includes a switching power supply chip model LM22670, a low-dropout linear voltage regulator chip model LP5907MFX-1.8, a CAN isolation transceiver chip model CTM1051KAT, and an Ethernet switch chip model IP175C. Chip, CODEC chip model TLV320AIC3106, processor chip model LPC4337JBD144, Flash memory chip model MX66L51235F.

[0012] The input end of the switching power supply chip is connected to the external DC12V power supply, and the output end is connected to the input end of the low-dropout linear voltage regulator chip and the DC3.3V power supply input of the CAN isolation transceiver chip, Ethernet switching chip, CODEC chip, processor chip, and Flash memory chip. end; the output end of the low-dropout linear voltage re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com