Thermal insulation material and processing technology thereof

A thermal insulation material and processing technology, applied in the field of new materials, can solve the problems of low compressive strength, easy aging, and low durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A thermal insulation material comprises the following components in parts by weight: 25 parts of rice husks, 26 parts of corn cob cores, 10 parts of volcanic cinder, 3 parts of calcium carbonate, 0.5 parts of bamboo fiber and 20 parts of adhesive.

[0052] The processing technology of thermal insulation material comprises the following steps:

[0053] a. Pulverization: pulverize rice husk, corn cob, volcanic slag and calcium carbonate:

[0054] b, sieving: sieve rice husk, corn cob core, volcanic cinder and calcium carbonate to 60 mesh;

[0055] c, make bamboo fiber: bamboo fiber is made diameter 0.5 millimeter, long 2 millimeters;

[0056] d. Stirring: Stir all raw materials evenly to obtain a mixture;

[0057] e. Molding: Use a mold to cure for 12 hours at a temperature of 5°C, and then demould.

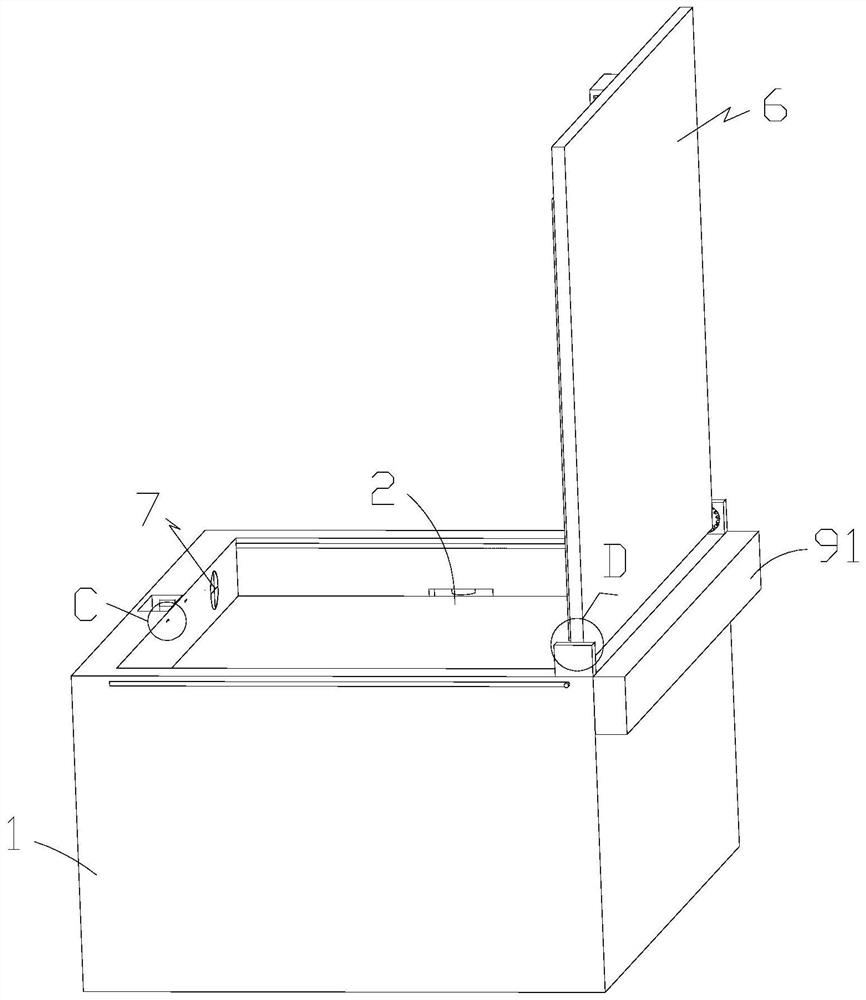

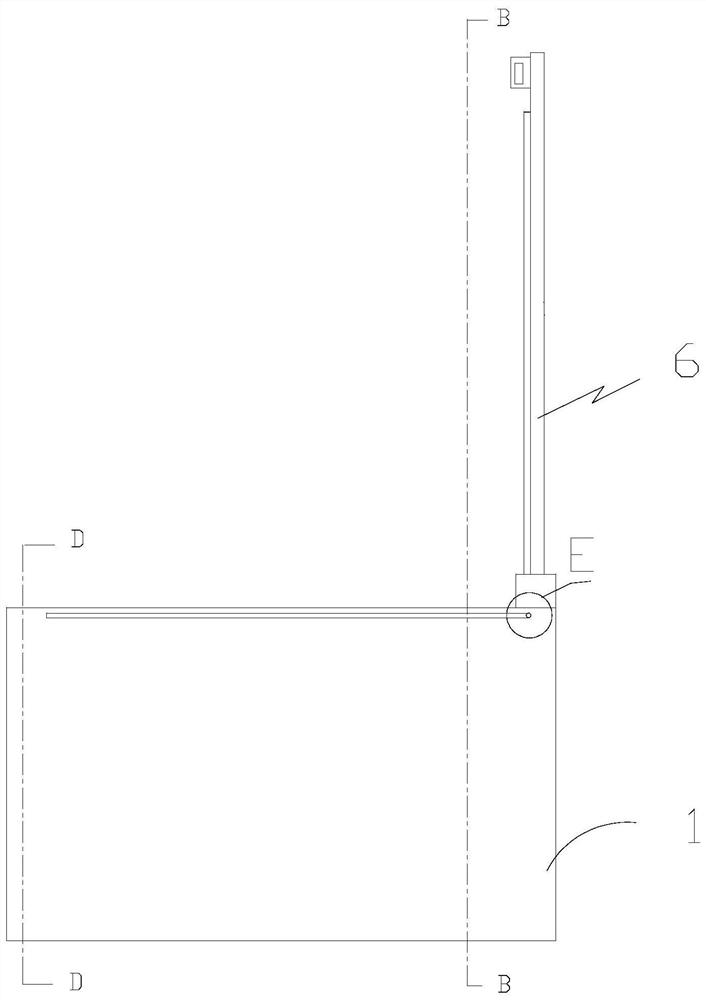

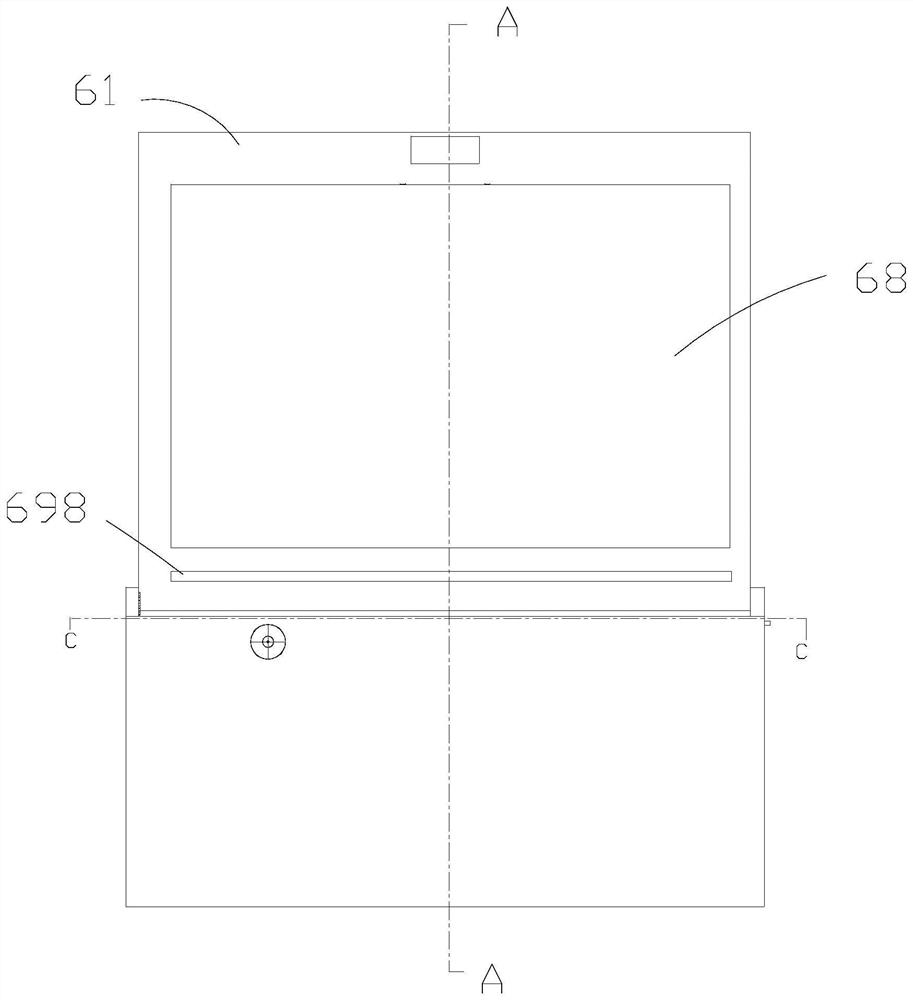

[0058] Such as Figure 1-19 As shown, the mold shown includes a main body 1, a lifting platform 2, a telescopic rod 3, a timer 4, a lifting plate 5, a cover plate 6, a f...

Embodiment 2

[0069] A thermal insulation material comprises the following components in parts by weight: 35 parts of rice husks, 34 parts of corn cobs, 15 parts of volcanic cinder, 5 parts of calcium carbonate, 1 part of bamboo fiber and 26 parts of adhesive.

[0070] The processing technology of thermal insulation material comprises the following steps:

[0071] a. Pulverization: pulverize rice husk, corn cob, volcanic slag and calcium carbonate:

[0072] b, sieving: sieve rice husk, corn cob core, volcanic cinder and calcium carbonate to 60 mesh;

[0073] c, make bamboo fiber: bamboo fiber is made diameter 0.5 millimeter, long 2 millimeters;

[0074] d. Stirring: Stir all raw materials evenly to obtain a mixture;

[0075] e. Molding: Use the mold to cure for 12 hours at a temperature of 5°C, and then demould

Embodiment 3

[0077] A thermal insulation material comprises the following components in parts by weight: 30 parts of rice husks, 28 parts of corn cobs, 13 parts of volcanic cinder, 4 parts of calcium carbonate, 0.8 parts of bamboo fiber and 23 parts of adhesive.

[0078] The processing technology of thermal insulation material comprises the following steps:

[0079] a. Pulverization: pulverize rice husk, corn cob, volcanic slag and calcium carbonate:

[0080] b, sieving: sieve rice husk, corn cob core, volcanic cinder and calcium carbonate to 60 mesh;

[0081] c, make bamboo fiber: bamboo fiber is made diameter 0.5 millimeter, long 2 millimeters;

[0082] d. Stirring: Stir all raw materials evenly to obtain a mixture;

[0083] e. Molding: Use a mold to cure for 12 hours at a temperature of 5°C, and then demould.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com