Underground diaphragm wall prefabricating method for built-in capillary tube heat exchanger

An underground diaphragm wall and capillary tube technology, applied in geothermal collectors, sheet pile walls, geothermal energy, etc., can solve the problems of inability to apply geothermal energy, floor space, and initial investment impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

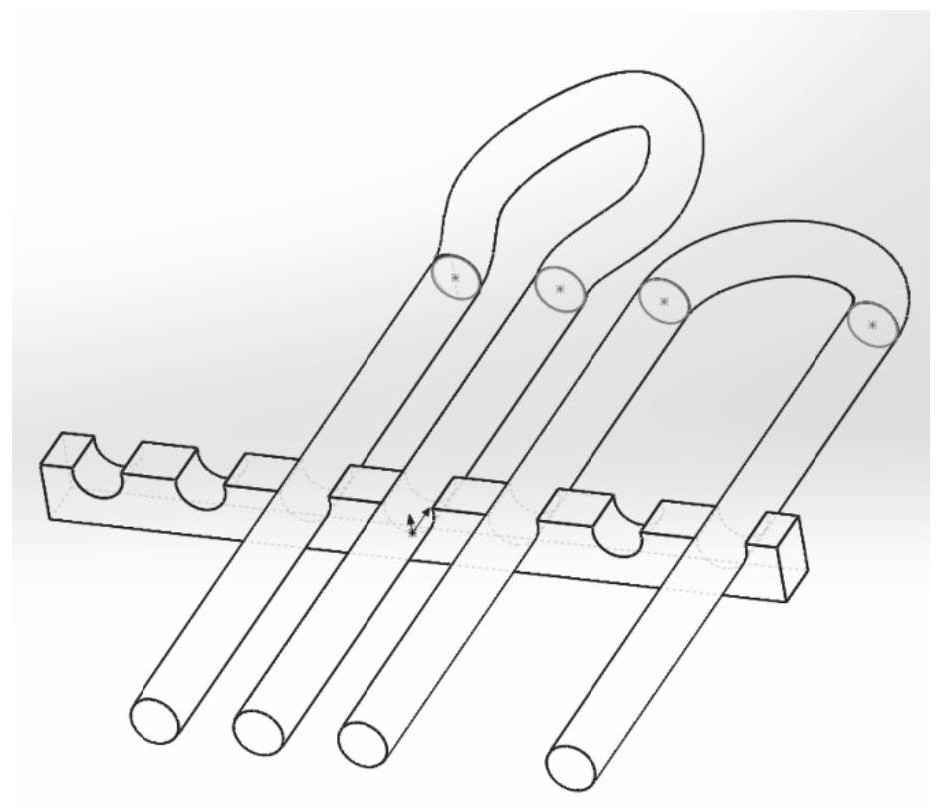

[0062] Embodiment 1 of the present disclosure provides a prefabrication process of an outer underground diaphragm wall with a built-in capillary heat exchanger, and the steps are as follows:

[0063] A prefabrication process of an underground diaphragm wall with a built-in capillary heat exchanger, including the construction of the underground diaphragm wall guide wall, drilling rig drilling, drilling and grasping machine to form grooves, pouring high-quality mud to protect the wall, inspecting the capillary, braiding the steel bar structure, fixing the capillary, and inserting the steel bar Structural, concrete pouring, capillary row connections, pressure testing, incorporating diaphragm walls.

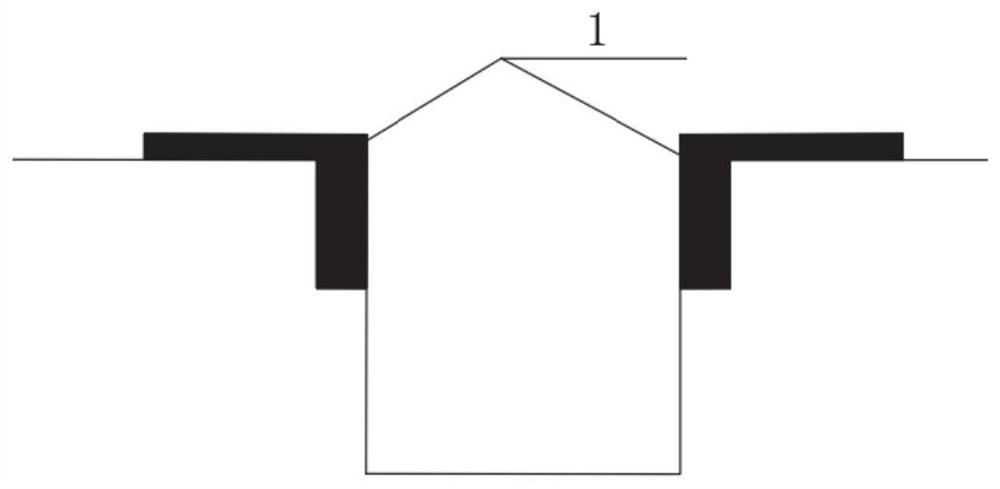

[0064] 1. Construction of underground diaphragm wall guide wall

[0065] like figure 1 As shown, the construction of the underground diaphragm wall guide wall 1 is to determine the construction scope of the subway station, reduce construction errors and lay a good foundation for the...

Embodiment 2

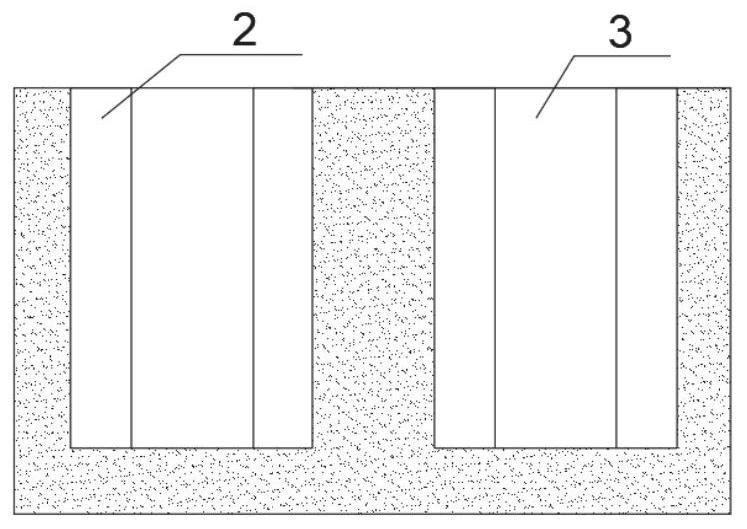

[0089] Embodiment 2 of the present disclosure provides a prefabrication process of an inner underground diaphragm wall with a built-in capillary heat exchanger. This embodiment is the case of two-layer continuous wall.

[0090] In the construction of some subway stations, the subway station directly uses the underground diaphragm wall as the enclosure structure. However, considering the water permeability of the underground diaphragm wall, some subway stations in recent years will directly build a waterproof structure on the outside or in the underground diaphragm wall when they are built. Build a layer of inner wall 12 as a supporting structure inside the inner side, and this layer of supporting structure is also called an underground diaphragm wall. Due to the use of space-time effects, the inner underground diaphragm wall can be constructed horizontally and extended vertically. This layer of underground diaphragm wall is connected with the outer layer of underground diaphra...

Embodiment 3

[0100] Embodiment 3 of the present disclosure provides an underground continuous wall prefabrication process with built-in capillary heat exchangers between walls.

[0101] like Figure 8 As shown, for embodiments 1 and 2, considering that the two-layer diaphragm wall 10, 12 may be equipped with two layers of capillary tubes will be redundant and inconvenient for construction, it may be considered to place the capillary tube in the middle of the two-layer diaphragm wall 10, 12. This built-in method can be independent of steel and concrete.

[0102] Concrete construction method and embodiment 1 and embodiment 2 different operations are: treat that the capillary row is bonded on the outer diaphragm wall 10 with adhesive after the foundation pit bottom layer construction is finished, and spray on the outer diaphragm wall 10 with cement mortar, thickness Just cover the capillary, and then follow the normal construction process of the subway station.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com