Hollow beam supporting structure and construction method thereof

A technology of supporting structure and construction method, which is applied in the direction of basic structure engineering, underwater structures, excavation, etc., and can solve the problems of strengthening the supporting strength of hollow beams, setting prestressed tendons in open hollow beams, and not being open.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

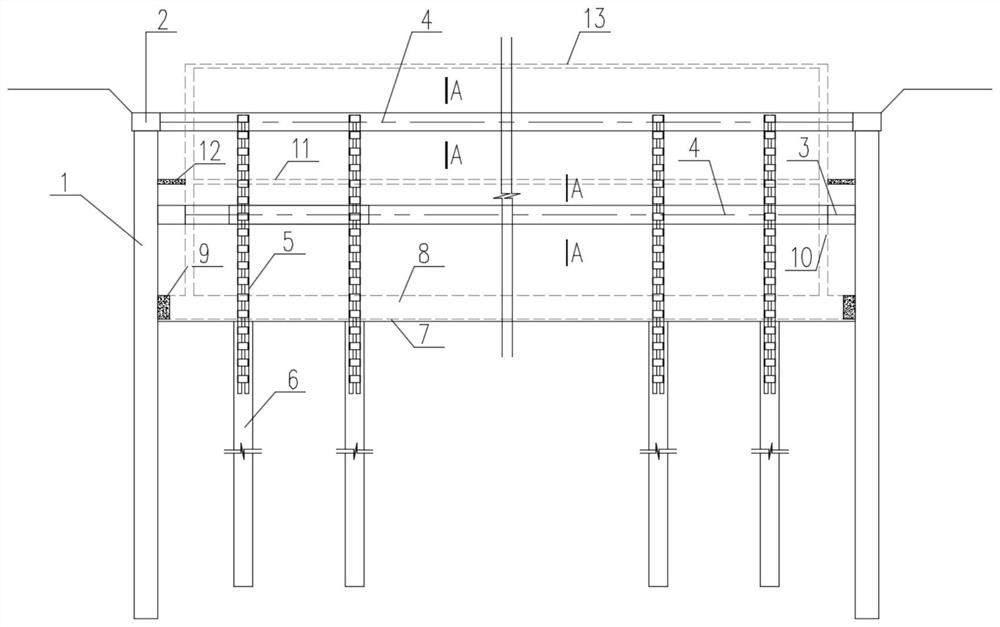

[0028] In this embodiment, the basement of a community is excavated, and the following construction techniques are used, see the attached figure 1 :

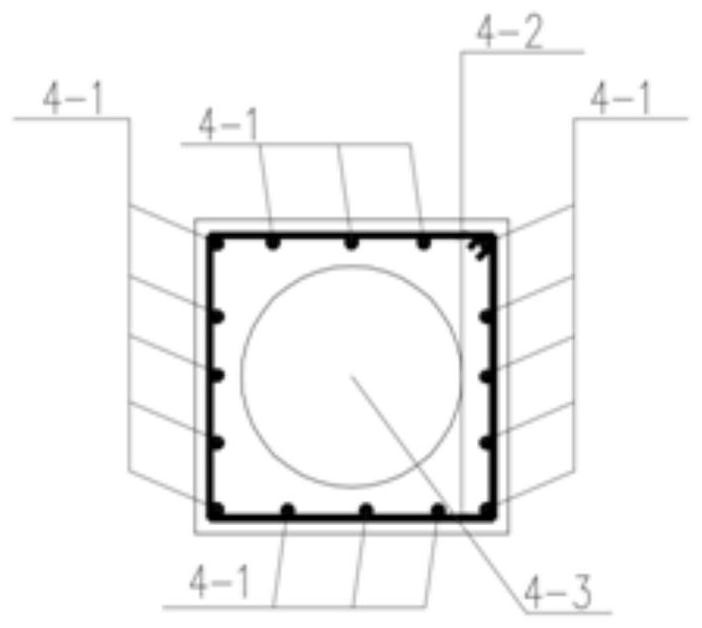

[0029] 1. Level the site, measure and set out the line, construct the support pile 1, the column 5 and the column pile 6, there are 8 support piles 1, and they are distributed in a rectangle, and the column 5 and the column pile 6 are arranged in the rectangle surrounded by the support pile 1 , the upright column 5 is located on the top of the upright pile 6, and there are four upright columns 5 and upright pile 6 respectively; the hollow beam 4 is prefabricated, and the shape of the hollow beam 4 needs to be prefabricated first, and the hollow beam 4 contains the main reinforcement 4-1 and the stirrup 4-2, Hollow 4-3, and hollow beam shape is square, in the present embodiment, hollow 4-3 is circular, see attached figure 2 , the cross-sectional area of the hollow 4-3 accounts for 80% of the cross-sectional area of the holl...

Embodiment 2

[0040] In this embodiment, the excavation construction is carried out on the submerged part of a certain subway, and the following construction technology is adopted,

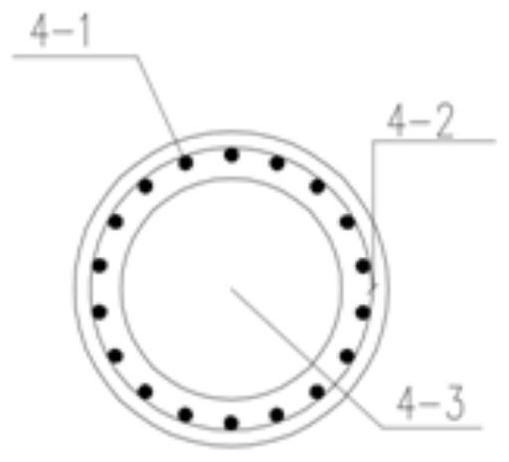

[0041] 1. Construct support piles, columns and column piles along the section direction of the subway tunnel; the hollow beams are made of cast-in-place, and the cast-in-place hollow beams contain main reinforcement and stirrups. image 3 , in the present embodiment, the hollow is square, and the ratio of the cross-sectional area of the hollow to the cross-sectional area of the hollow beam is 70%, which fully reduces the weight of the hollow beam; The hollow inner wall is parallel and evenly distributed, and there are also multiple stirrups, and each stirrup is basically perpendicular to the main reinforcement. The main reinforcement is made of ordinary steel bars, and the stirrups are made of special steel bars.

[0042] 2. Excavate to the first support level, construct the crown beam, the crown beam adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com