Multifunctional disc-type integrated stove

An integrated stove and multi-functional technology, applied in the field of integrated stoves, can solve problems such as singleness, poor adaptability, and non-compliant stove head switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

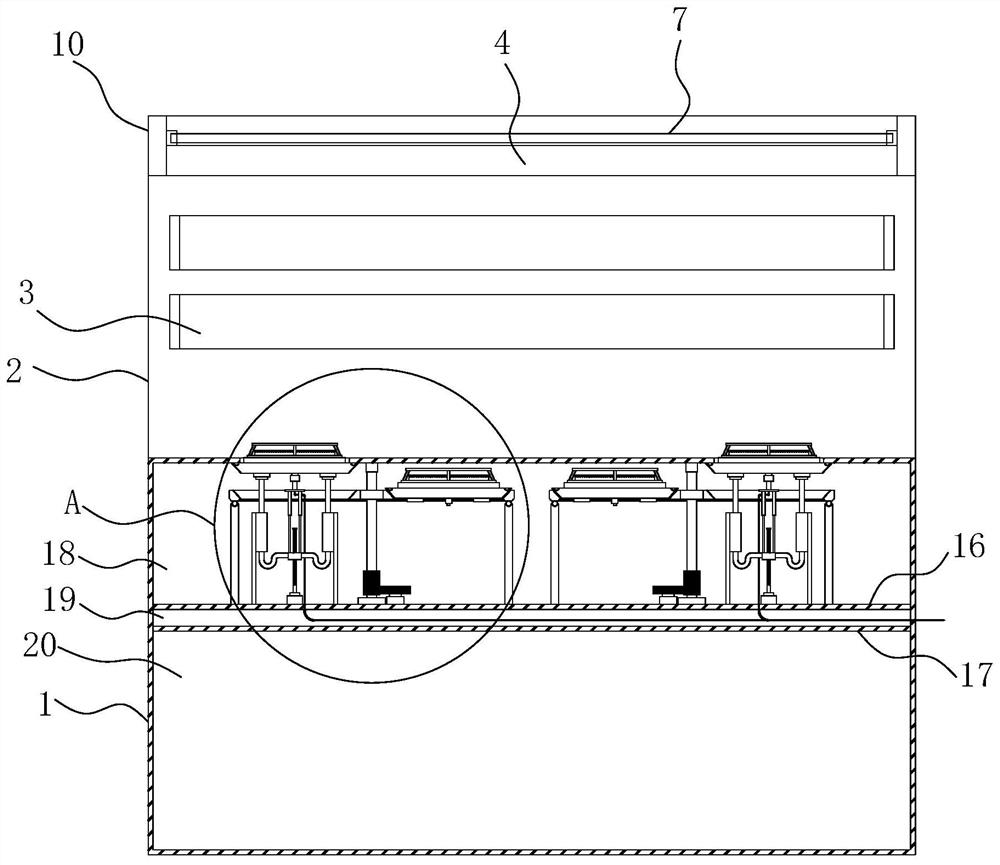

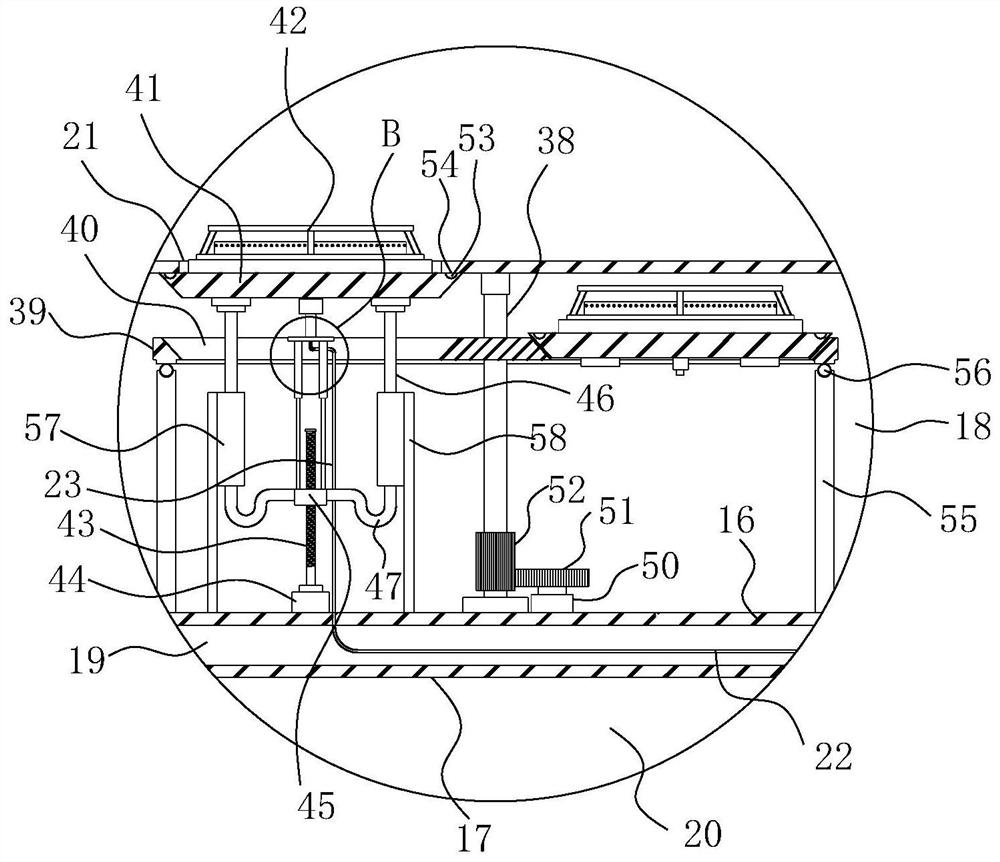

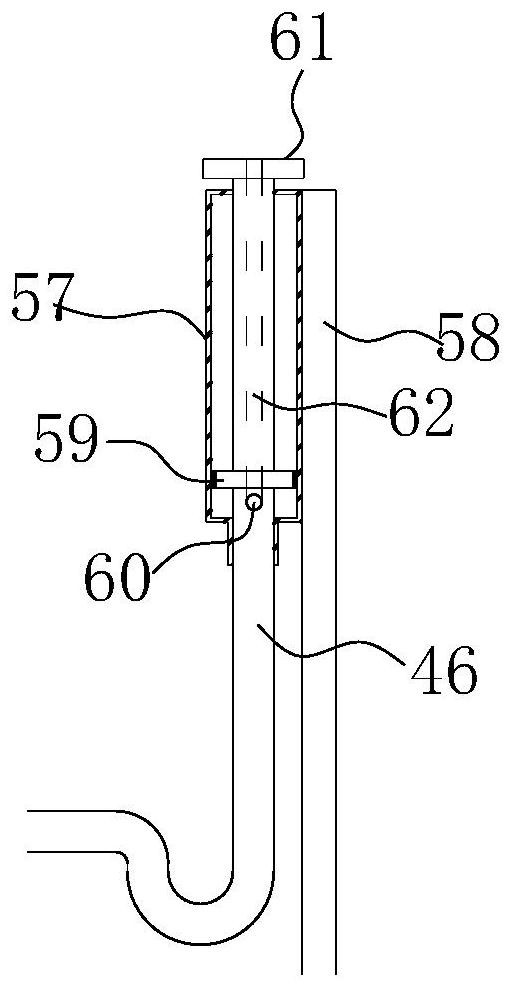

[0035] Such as Figure 1-11 The shown integrated cooker is the same as the traditional integrated cooker in that the integrated cooker according to the present invention also includes an integrated cooker main body 1, which mainly serves as a cooker cabinet, and a range hood, Pot and dish racks, disinfection cabinets, etc.

[0036] One big difference of the present invention is: combine figure 1 , 9 As shown in -11, the top of the rear side of the integrated stove main body 1 is provided with an inverted L-shaped fume collection hood, and a fume passage is arranged inside the fume collection hood, and the fume passage can communicate with the range hood in the integrated stove main body 1. The front side of the vertical section 2 of the fume hood is provided with a smoke inlet 3 through which oil fume enters the inside of the fume collecting hood. The top plate 4 of the smoke hood is provided with an extension plate 5, which, as the name implies, is a plate body extending t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com