A Contour Error Estimation Method for Multidimensional System Based on Simplified Newton Method

A multi-dimensional system and contour error technology, applied in general control systems, control/regulation systems, computer control, etc., can solve problems such as large amount of calculation, long solution time, etc., to reduce calculation amount, simplify calculation form, and improve response speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

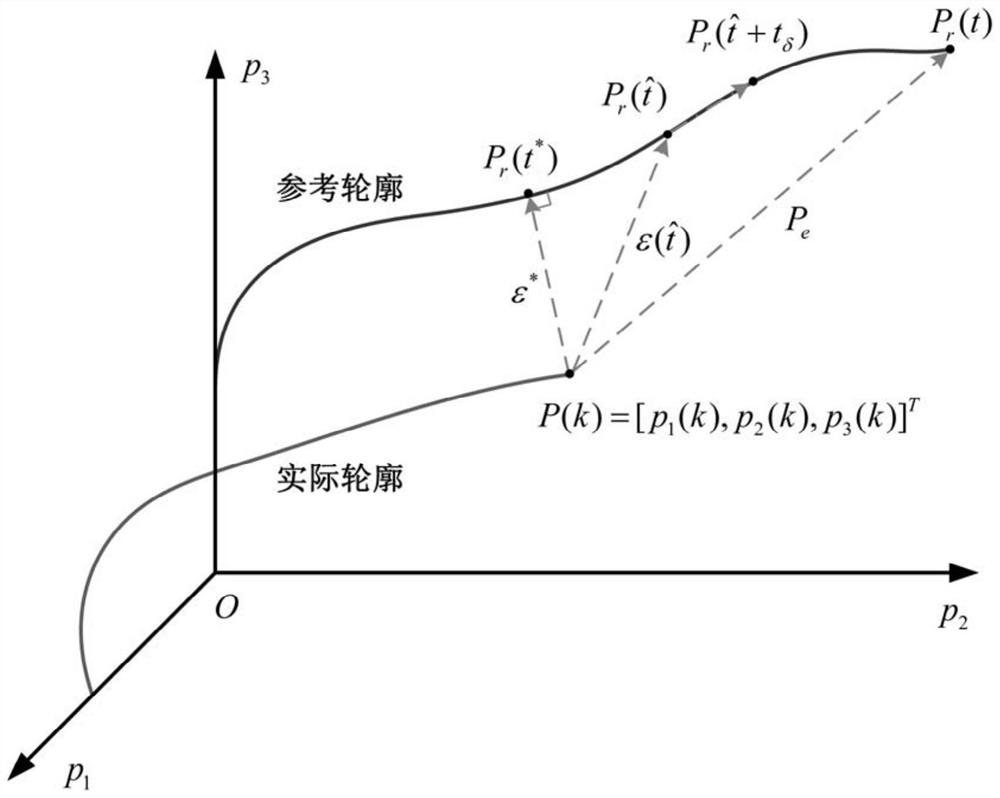

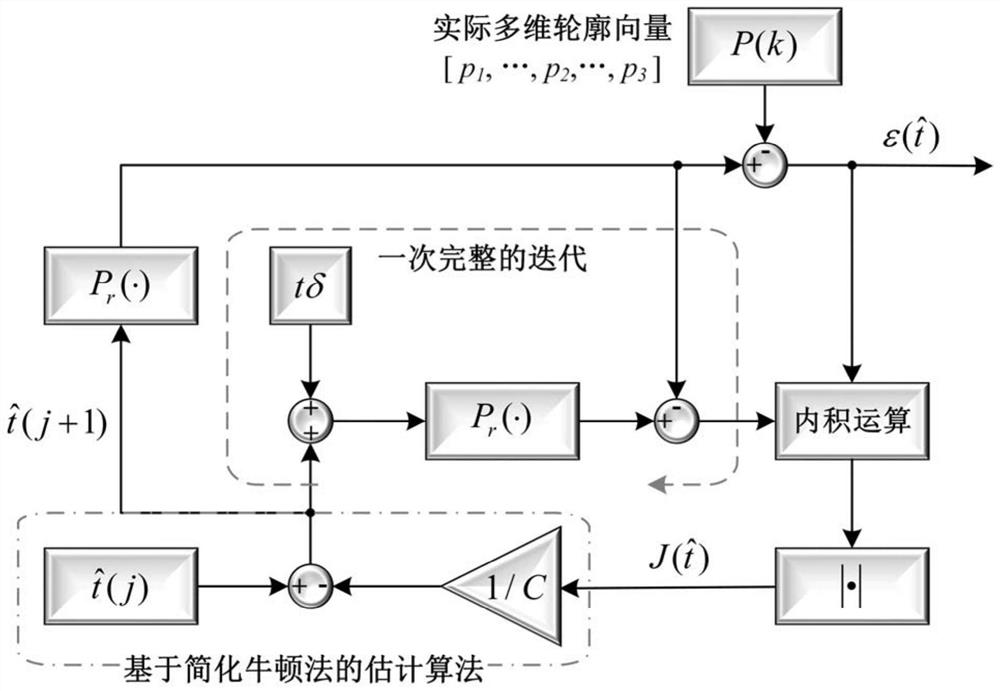

[0043] Specific implementation mode one: refer to figure 1 and figure 2 This embodiment is described in detail. A method for estimating the contour error of a multi-dimensional system based on the simplified Newton method described in this embodiment includes the following steps:

[0044] Step 1: Initialize various parameters and variables of the multidimensional system: First, parameterize the reference contour trajectory of the multidimensional system as a multidimensional vector P r (t)=[p r1 (t),p r2 (t),...,p rn (t)] T , where t represents the system time, p ri (t), i=1, 2,..., n represents the reference position of each dimension space in the numerical control machining operation. Then, define the actual contour trajectory of the multidimensional system as

[0045] P(t)=[p 1 (t),p 2 (t),...,pn (t)] T , considering the actual situation of engineering applications and the discrete characteristics of computer control, it is discretized as P(k)=[p 1 (k),p 2 (k),...

Embodiment

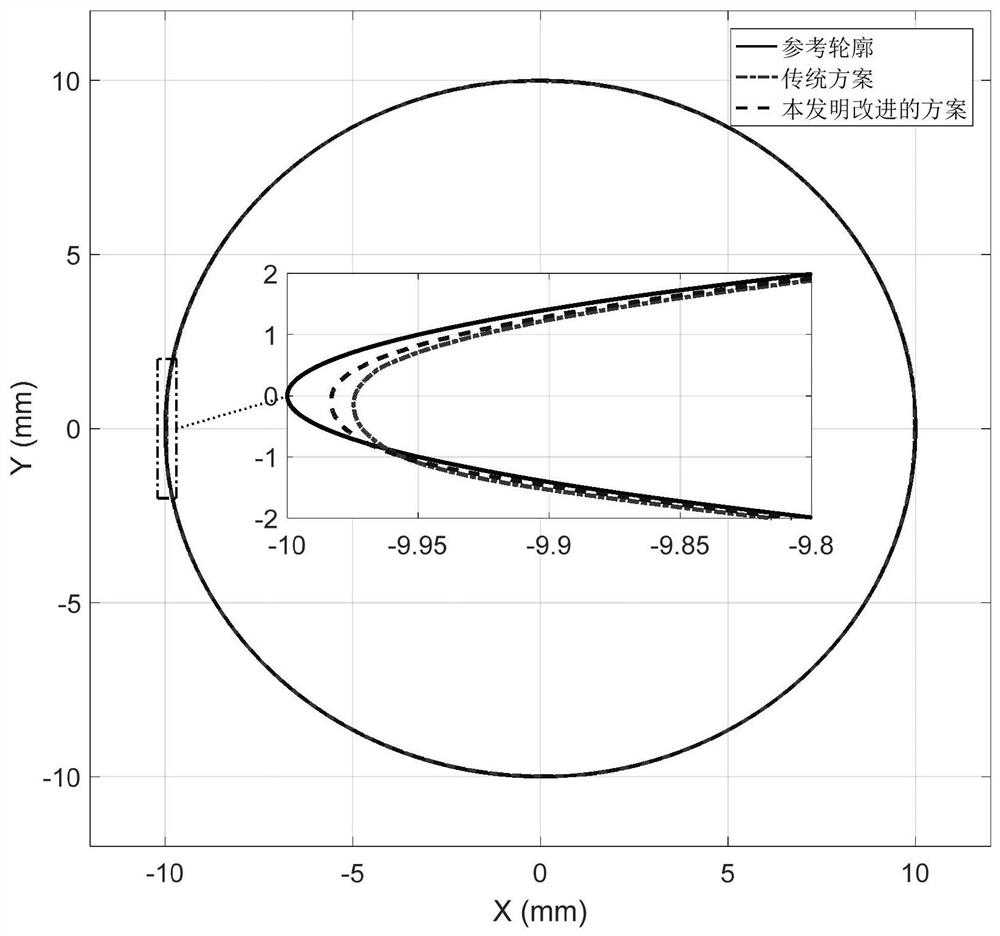

[0065] The present invention will be based on the X-Y linear motor platform, and the error estimation and tracking control of the slow circular contour and the fast star contour in the numerical control machining process will be described as an embodiment. It should be pointed out that the present invention is mainly aimed at the estimation scheme of the contour error of the multi-dimensional system, and the introduction of the control method is to better illustrate the validity and superiority of the error estimation scheme. The invention can be applied to the contour tracking control scheme of various precision machine tools and processing platforms in the numerical control processing industry, and can realize accurate contour error estimation of multi-dimensional systems under complex and extreme contour conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com