Improved drawer side plate and back plate assembly structure

A technology for assembling structure and back panel, which is applied to drawers, furniture parts, household appliances, etc., can solve the problems of poor connection effect of back panel and large size of side panels, and achieves improved user experience, low manufacturing cost, and strong practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

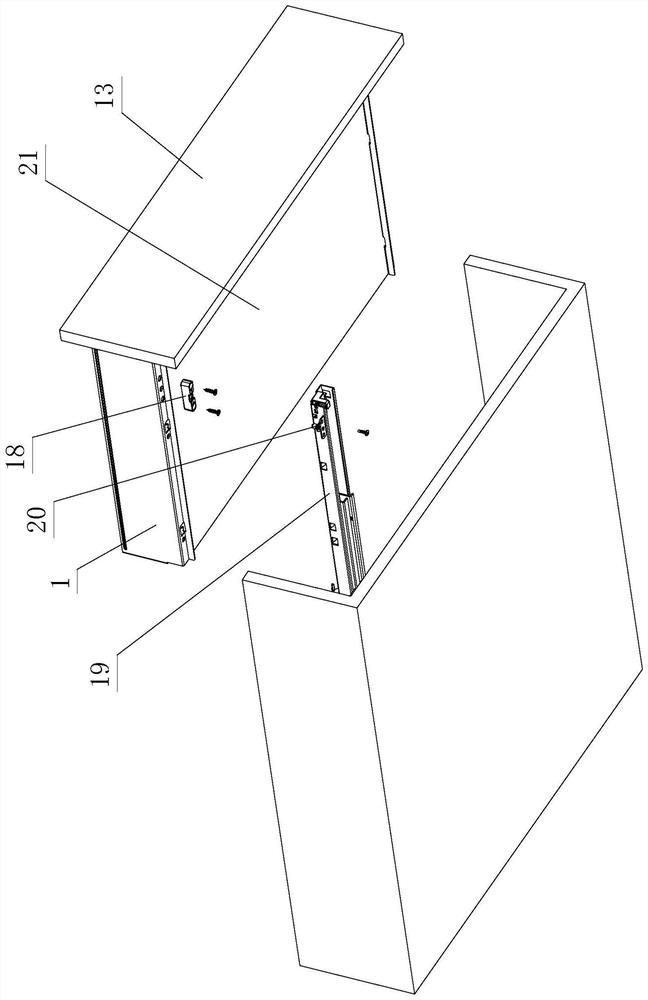

[0044] see Figure 1-Figure 10 , the improved assembly structure of drawer side panels and back panels includes a side panel body 1 and a back panel 2, the back panel 2 is made of metal material, and the left and right sides are separately provided with adapters 3, the adapters 3 is provided with an assembly part 4; the side plate body 1 is made of metal material, and a planar side part 5 is arranged on it, and the rear end of the side part 5 is integrally bent with a rear connecting part 6, and through The rear connecting portion 6 is mated with the assembly part 4 to realize the mated connection between the side panel body 1 and the back panel 2 .

[0045] The back panel 2 is made of metal material, thereby reducing the production cost of the back panel 2, and then connected with the rear connection part 6 of the side panel body 1 through the cooperation of the adapter 3 and the assembly part 4, thereby effectively simplifying the back panel 2. The assembly process with the...

no. 2 example

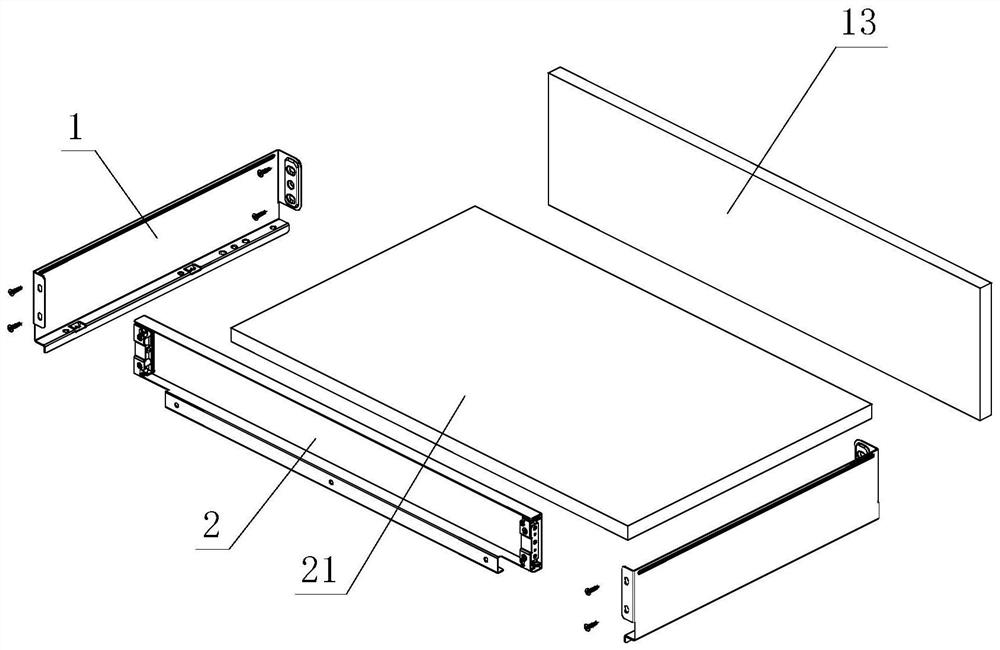

[0065] see Figure 11 , Figure 12 , the improved assembly structure of drawer side panels and back panels is different from the first embodiment in that: the drawer bottom panel 21 is a metal sheet metal part, which is set separately and supported on the supporting part 16 and the moving slide rail 19 .

[0066] Other unmentioned parts are the same as the first embodiment.

no. 3 example

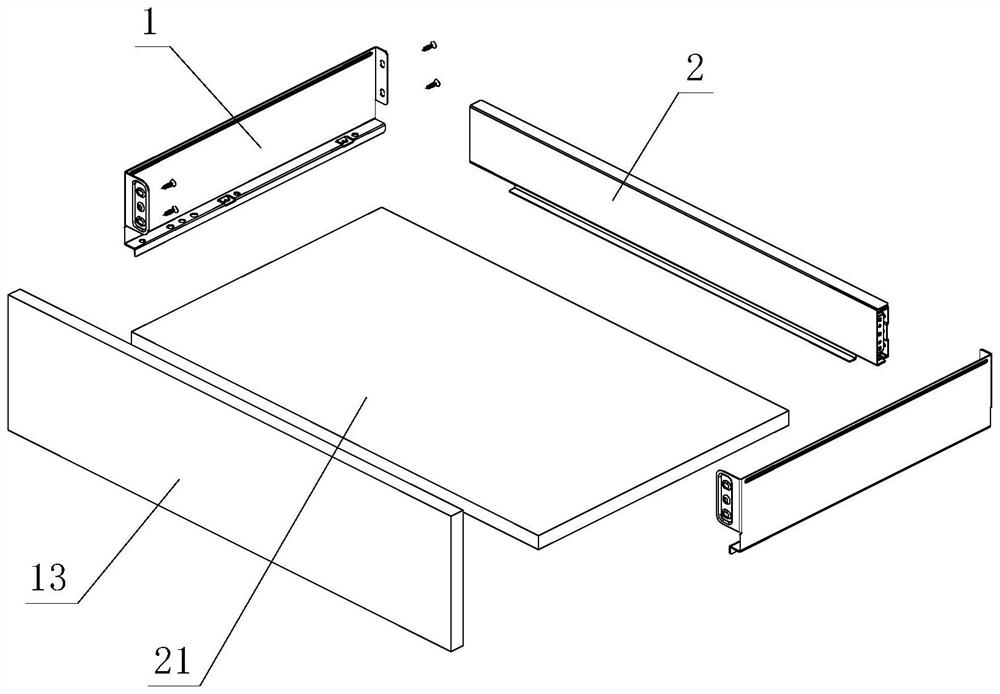

[0068] see Figure 13 , Figure 14 The improved drawer side panel and back panel assembly structure differs from the first embodiment in that: the drawer bottom panel 21 is integrally provided on the support portion 16 and supported above the movable slide rail 19 .

[0069] Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com