Spray freezing tower system

A spray freezing and spray tower technology, which is applied in the field of large-scale production spray freezing tower systems, can solve the problems of operator safety hazards, easy melting of microspheres, and bumping, so as to reduce operating costs and safety, and reduce sticky walls phenomenon, the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Exemplary embodiments of the present disclosure are described below with reference to the accompanying drawings. It should be understood that these specific descriptions are only used to teach those skilled in the art how to implement the present disclosure, but are not intended to exhaust all possible ways of the present disclosure, nor are they used to limit the scope of the present disclosure.

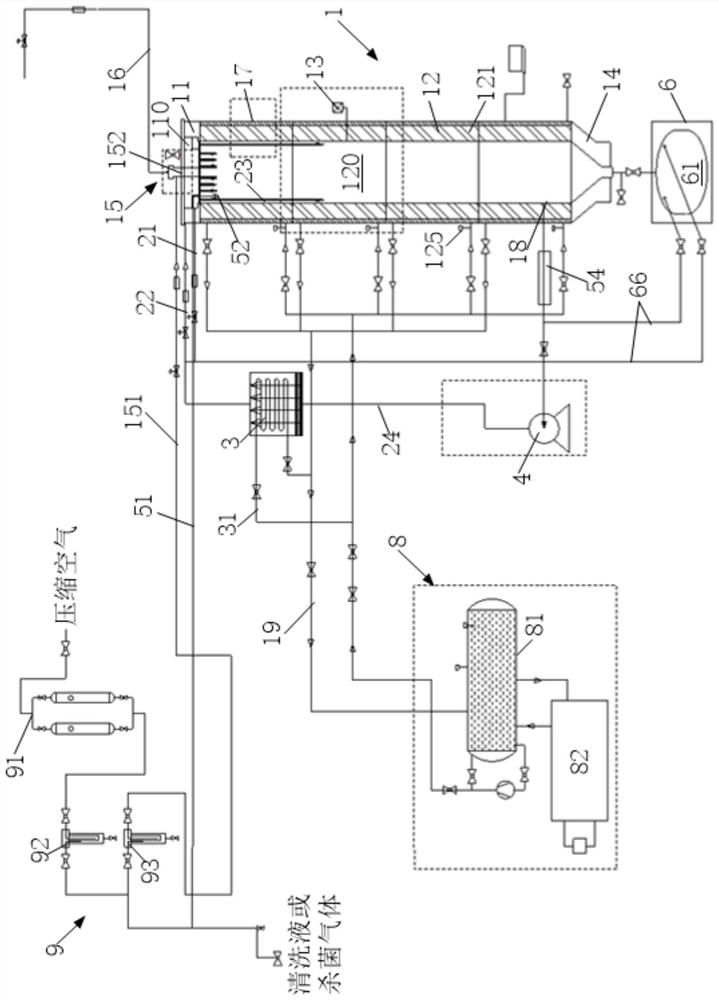

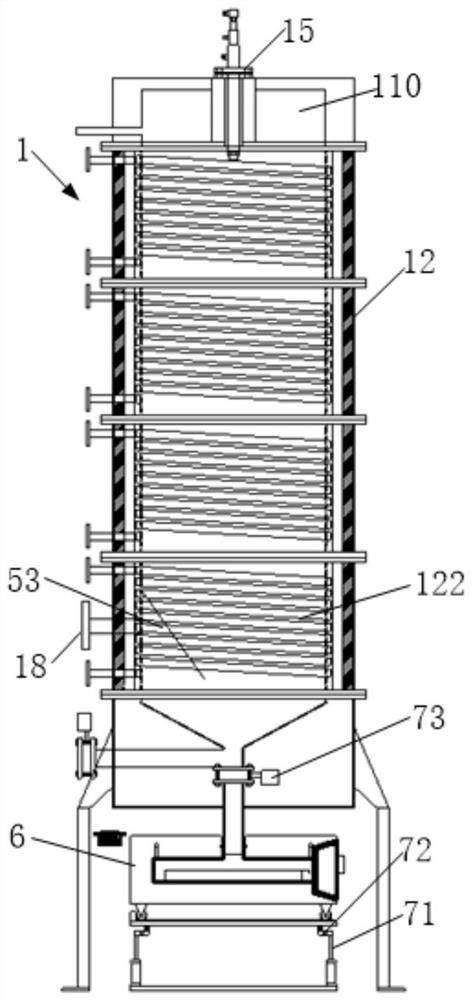

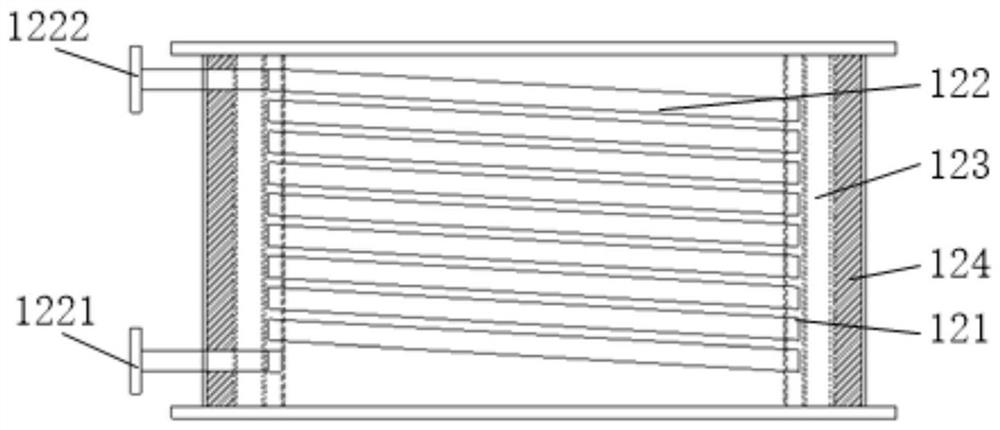

[0039] Such as Figure 1 to Figure 3 As shown, the present disclosure provides a new type of spray freezing tower system. The spray freezing tower system includes a spray tower 1 , a heat exchange medium supply system 8 and an air supply system 9 . Materials to be prepared can be frozen in the spray tower 1 .

[0040] The heat exchange working medium supply system 8 includes a heat exchange working medium container 81 and a temperature control system 82. The heat exchange working medium container 81 (such as an oil tank) contains a heat exchange working medium, such as silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com