Print head self-cleaning and control system for architectural 3D printing

A 3D printing and control system technology, which is applied in the direction of cleaning hollow objects, clay preparation devices, cleaning methods and utensils, etc., can solve the problems of low degree of automation and untimely cleaning of printing head cleaning devices, and achieve high degree of automation and ensure safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

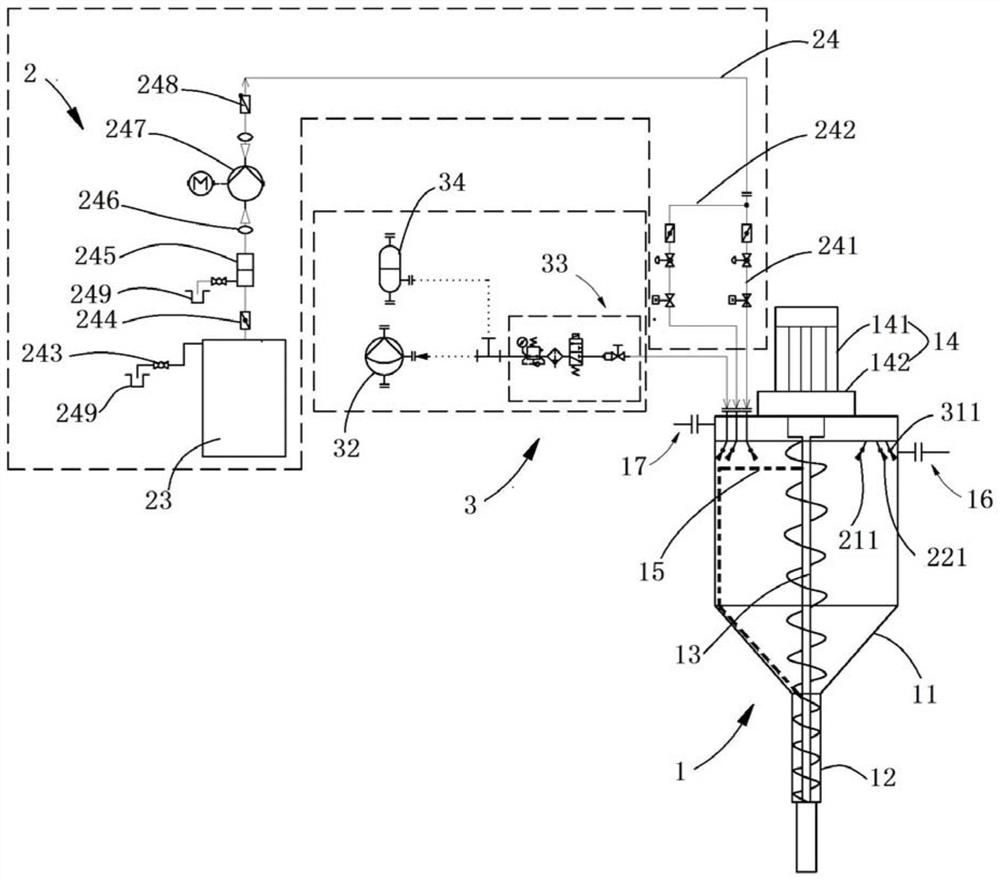

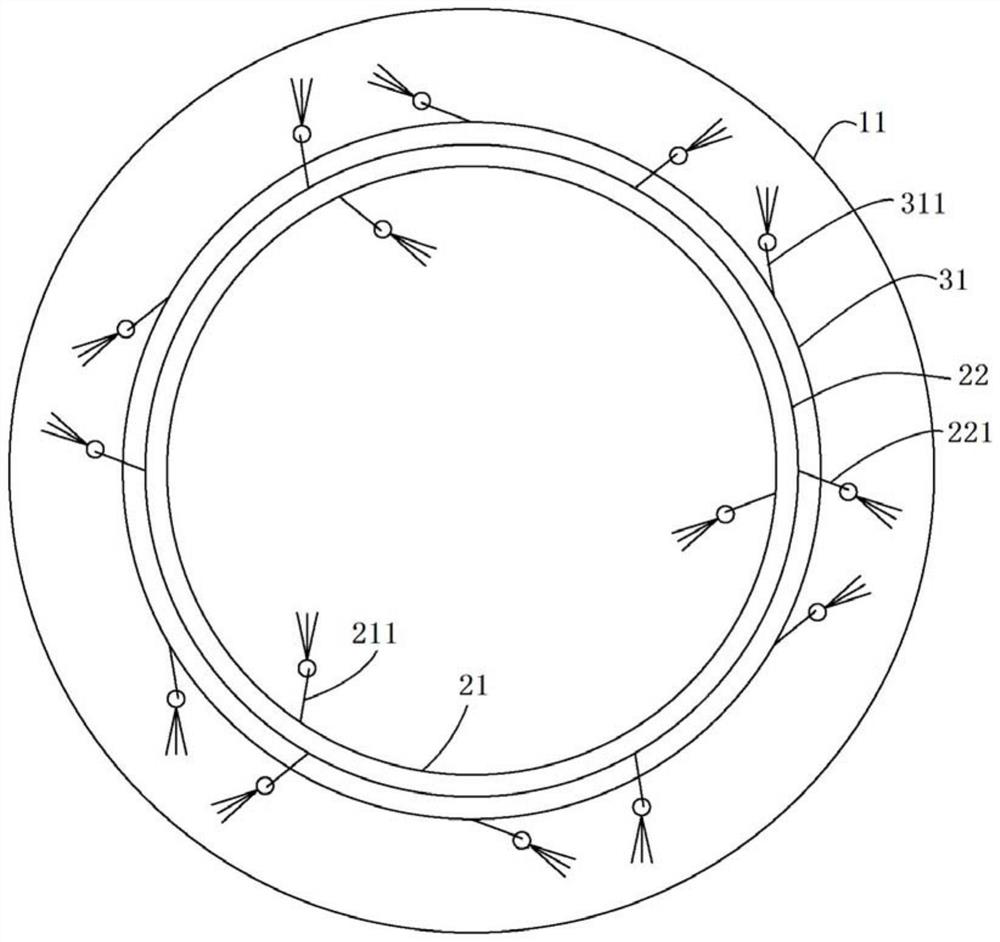

[0027] see figure 1 , figure 2 As shown, the present invention provides a printing head self-cleaning and control system for building 3D printing, including: printing head 1, high-pressure water supply device 2, compressed air supply device 3 and high-pressure water supply device 2 and compressed air supply The remote control platform (not shown) electrically connected to the device 3, the self-cleaning and control system of the printing head used for building 3D printing in the present invention, after the printing is completed, the high-pressure water supply device 2 is controlled by the remote control platform to clean the inner wall of the printing head. Timely flushing, through the control platform to control the compressed air supply device 3 to purge the print head 1, quickly and timely clean up the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com