Forming process of automobile front lower control arm

A molding process and control arm technology, which is applied in the field of molding process of front and lower control arms of automobiles, can solve the problems of bulky molding die, irregular shape of front and lower control arms, complicated demoulding mechanism of molding die, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

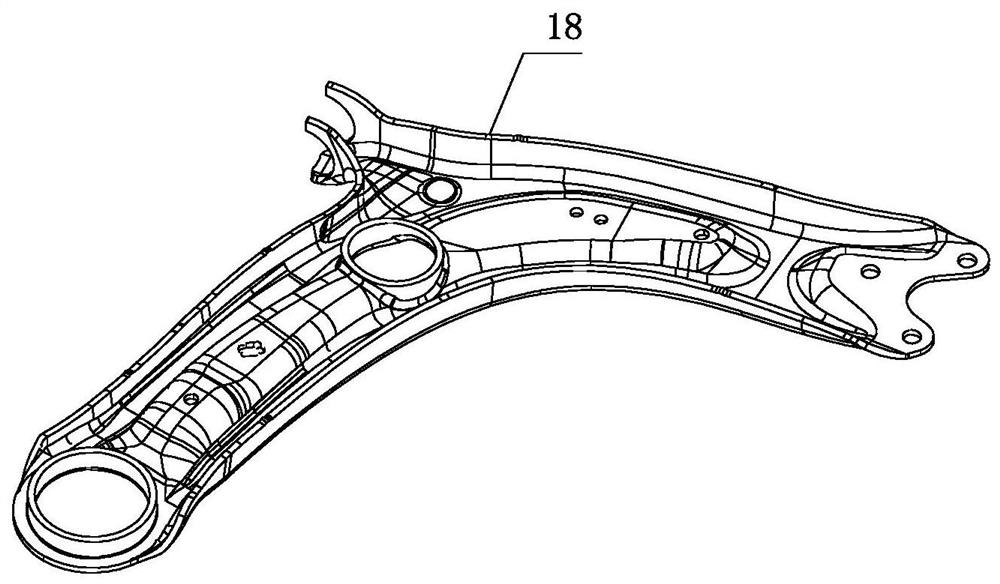

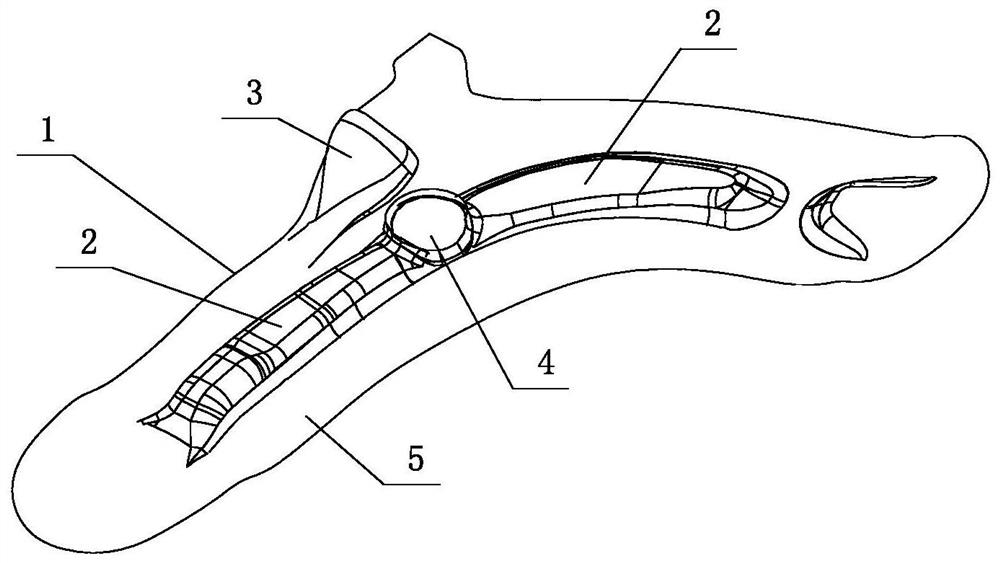

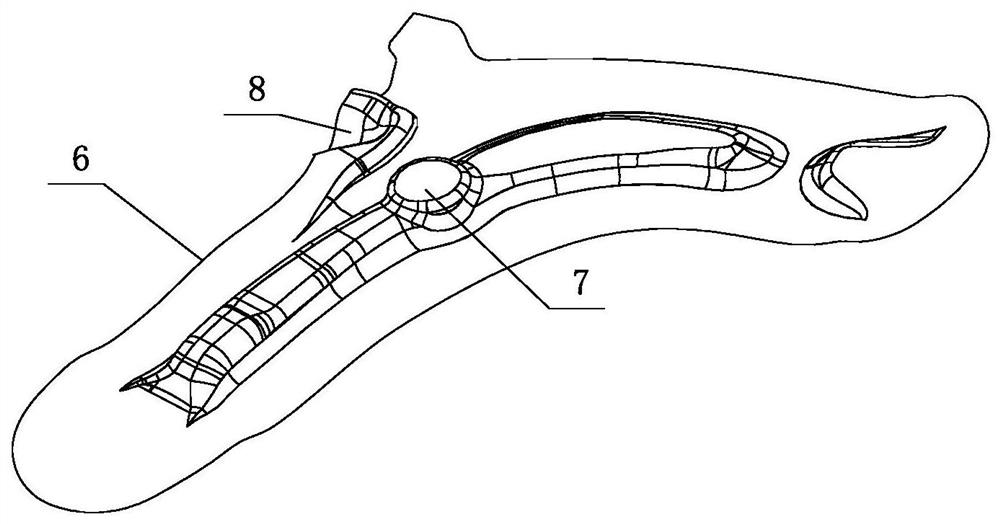

[0038] combine Figure 1 to Figure 10 As can be seen from the product forming process structural schematic diagram of the molding process of the lower front control arm of the automobile shown in the present invention, in the molding process of the lower front control arm of the automobile, two blank plates are symmetrically formed and shaped at a time, and it is characterized in that it includes the following steps:

[0039] 1) The blank plate is stretched and formed for the first time by a forming mold to obtain a semi-finished product 1 formed at one time, and the middle part of the semi-finished product 1 along the length of the blank plate has an upwardly convex rib 2 and a corner of the rib 2 There is an upwardly swollen middle part bulge 3, an upwardly bulging corner bulge 4 at the flanging of the corner of the blank plate, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com