Tank surface polishing method

A tank body and grinding mechanism technology, which is applied in the direction of grinding machines, abrasive belt grinders, grinding racks, etc., and can solve the problems such as troublesome angle and stroke adjustment of the grinding mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

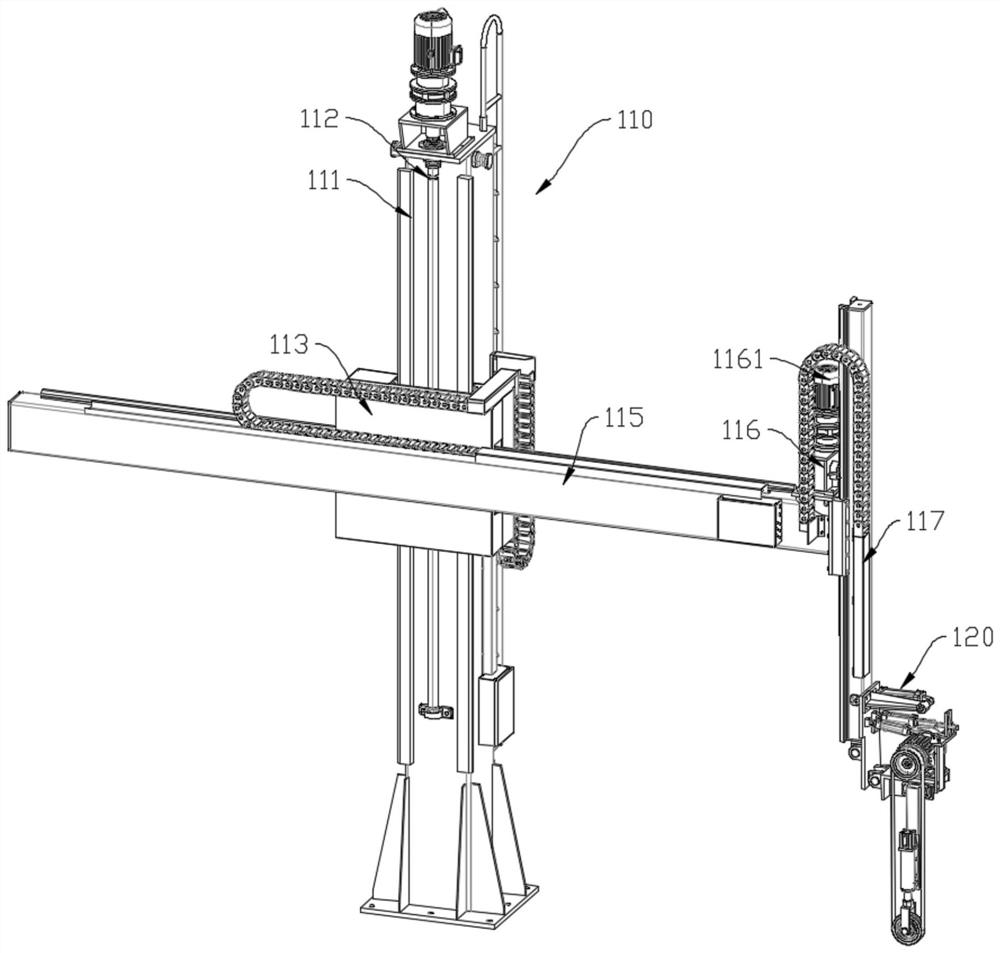

[0062] Such as figure 2 As shown, a tank body grinding machine is used for grinding and polishing the surface of the tank body, mainly including an adjustment device 110 and a grinding device 120, wherein the adjustment device 110 is used to adjust the position of the grinding device 120 in the horizontal and height directions For adjustment, the grinding device 120 is used for grinding the tank body 300 . The specific structure and working principle of the grinder will be described in detail below.

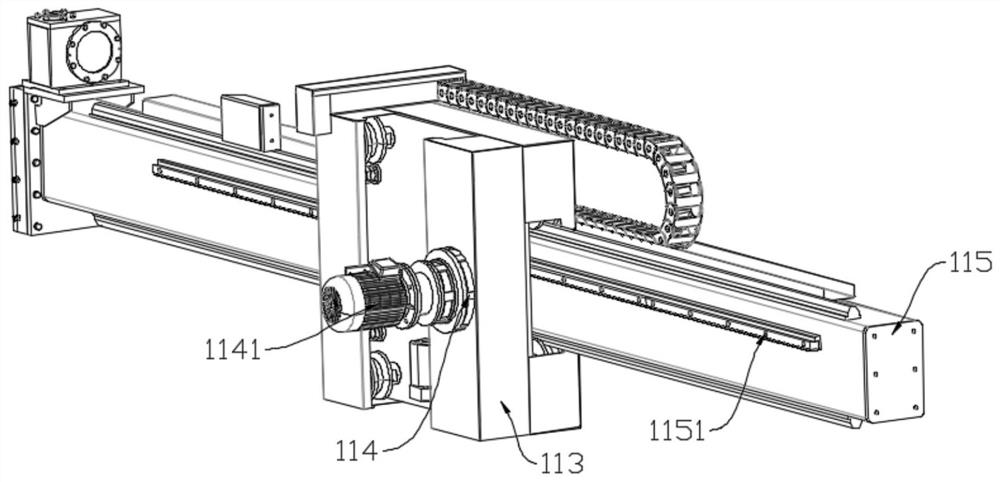

[0063] Such as figure 2 As shown, the adjustment device 110 includes a frame 111 , a screw mandrel lifting mechanism 112 , a lifting slider 113 , a horizontal driving mechanism 114 , a horizontal slider 115 , a grinding head lifting mechanism 116 and a grinding head slider 117 .

[0064] Wherein, the frame 111 is the installation main body, and is a column structure arranged vertically. Both sides of the frame 111 are provided with slide rails along the height direction, and...

Embodiment 2

[0078] A tank body fixing device, used to fix the tank body 300 and control the rotation of the tank body 300 when grinding the surface of the tank body 300, and polish and polish each position of the tank body 300. The specific structure and The working principle is described in detail.

[0079] Such as Figure 7 to Figure 10 As shown, the tank fixing device mainly includes a turntable 210 , a base 220 and a tank 300 . Wherein, a gear ring 214 is fixedly installed on the lower end surface of the turntable 210 , and a rotating support 215 is fixedly installed on the lower end surface of the gear ring 214 , and the rotating support 215 is rotatably installed on the base 220 . Specifically, the base 220 is fixed on the ground, and the center of its upper end surface is provided with a cylindrical protruding shaft. The rotating support 215 is a cross-shaped support structure, and its cross-shaped hinge is provided with a through hole or a groove matching the cylindrical protrudi...

Embodiment 3

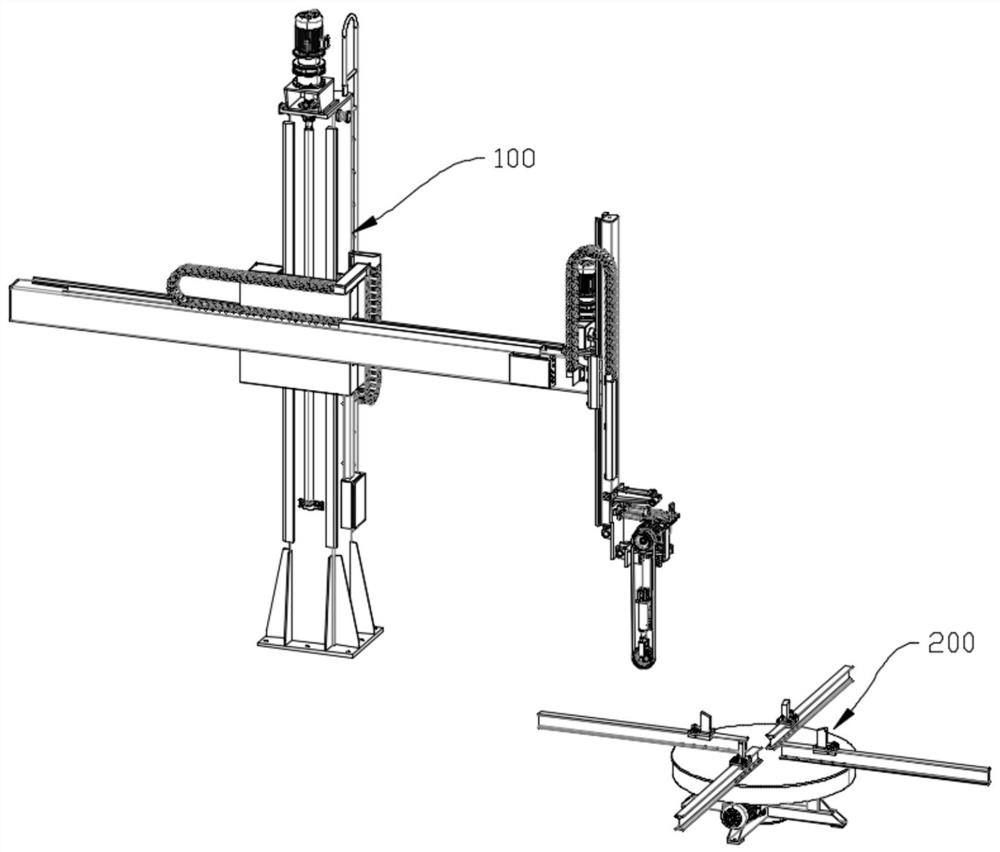

[0090] Such as figure 1 As shown, a tank body surface grinding equipment is used for grinding and polishing the surface of a tank body 300 , and mainly includes a tank body grinding machine 100 and a tank body fixing device 200 . Wherein, the can body grinding machine 100 adopts the can body grinding machine of Embodiment 1, and the tank body fixing device 200 adopts the tank body fixing device of Embodiment 2.

[0091] The tank body surface grinding equipment can adjust the angle of the grinding mechanism 124 twice according to the shape of the tank body 300 to complete the precise grinding of each position of the large tank body 300, and the grinding is comprehensive, and it can effectively prevent the grinding mechanism 124 from being adjusted. Collision with the tank body 300 or other parts during the angle prevents the grinding mechanism 124 and the tank body 300 from being damaged. In addition, the fixing of the tank body 300, especially the large tank body 300, is fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com