A solid hazardous waste pyrolysis equipment

A technology for hazardous waste and equipment, applied in the field of solid hazardous waste pyrolysis equipment, can solve the problems that material residue is easy to remain inside the cylinder, the material is not uniformly heated, and the filter screen is deformed, so as to avoid residues, reduce residues, and improve uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

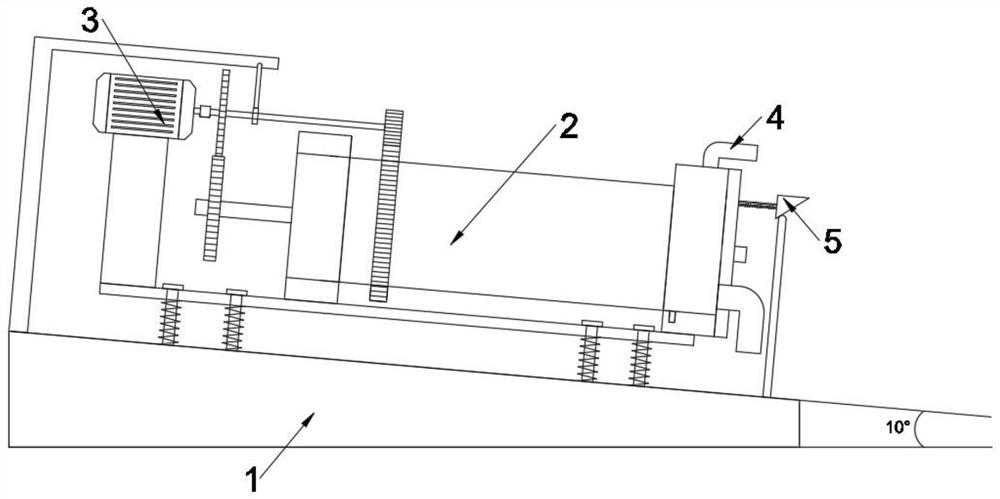

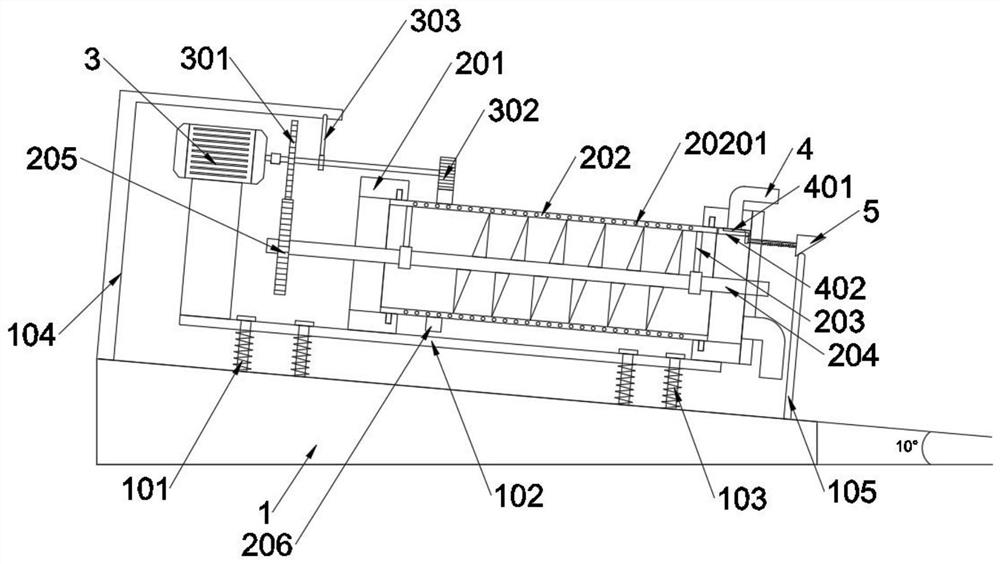

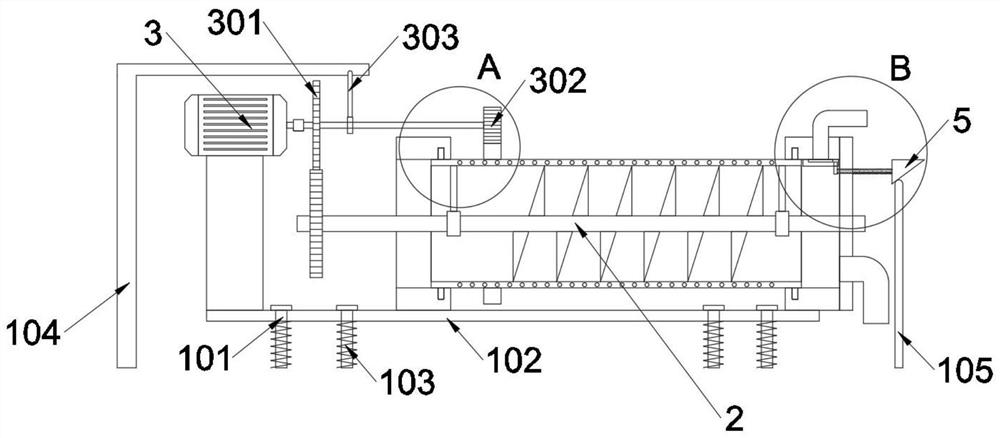

[0033] as attached figure 1 to attach Figure 8 Shown:

[0034] The present invention provides a solid hazardous waste pyrolysis equipment, including a base 1 and a force-bearing block 504; a driving structure 2 is installed on the base 1, and a driving motor 3 is installed on the base 1; a smoke exhaust pipe is installed on the driving structure 2 4, and a cleaning structure 5 is also installed on the driving structure 2; refer to as image 3 with Image 6, the base 1 also includes a force seat 104, the force seat 104 is welded on the base 1, and the force seat 104 is an L-shaped structure; the drive motor 3 also includes a toggle lever B303, and the toggle lever B303 is installed on the drive motor 3 On the rotating shaft, and the toggle lever B303 is in contact with the force seat 104, and when the toggle lever B303 rotates, the rectangular seat 102 is in a reciprocating state up and down, so that the impact between the rectangular seat 102 and the sliding bar A101 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com