Dust hood and converter three-time dust removal system thereof

A technology of dust removal system and dust removal hood, which is applied in the manufacture of converters, etc., and can solve the problems of large collection hood area and enhanced smoke and dust diversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

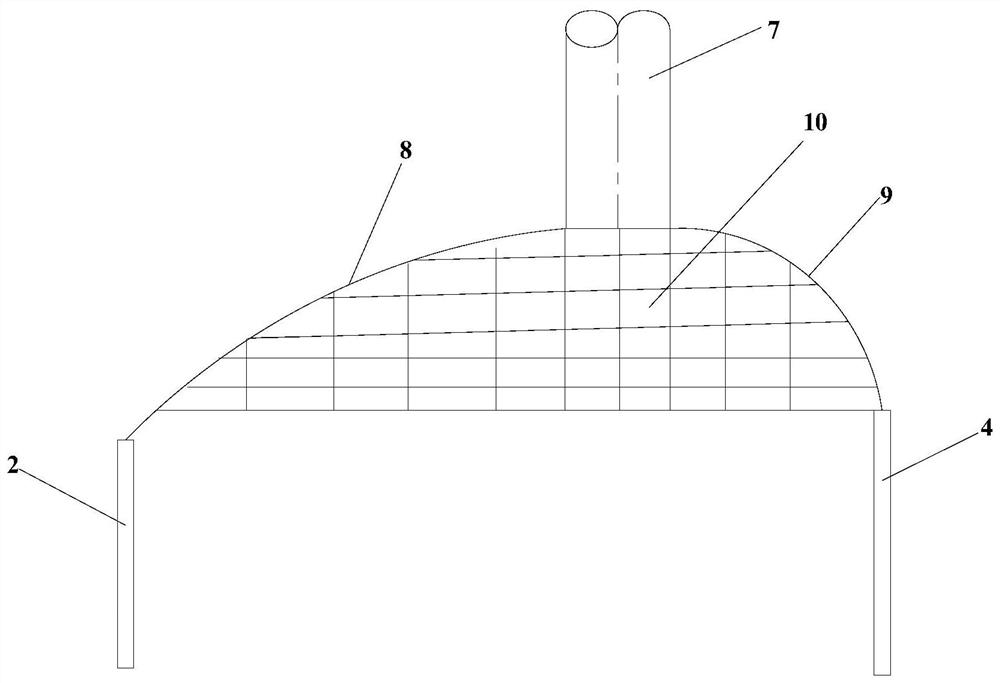

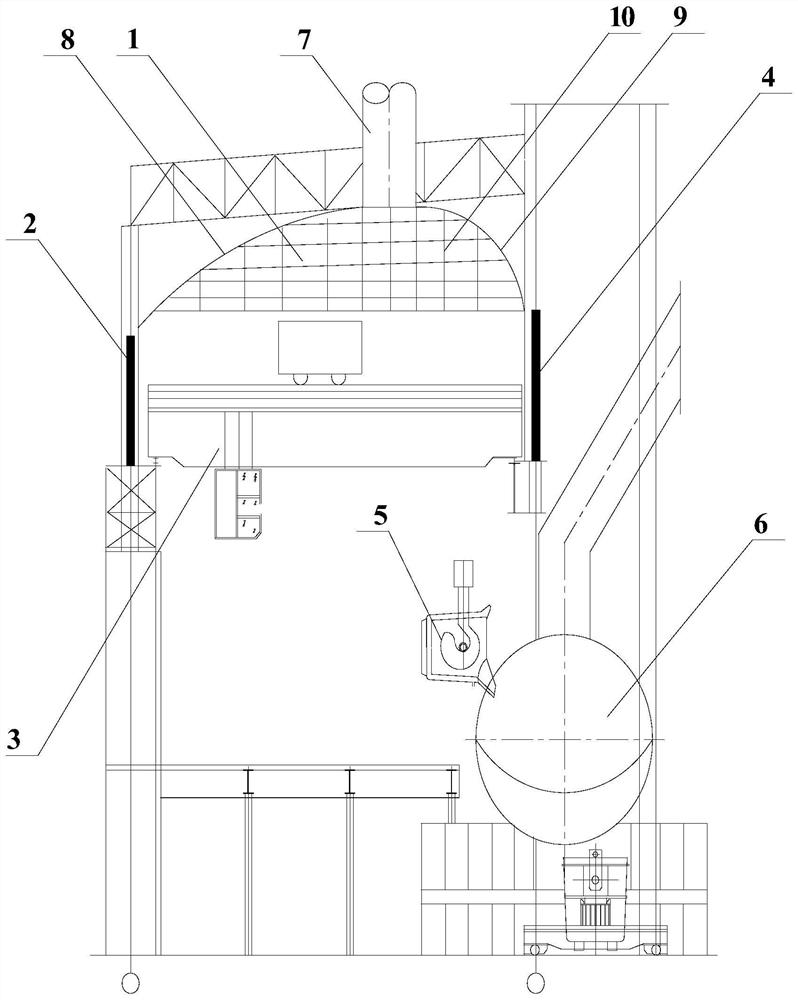

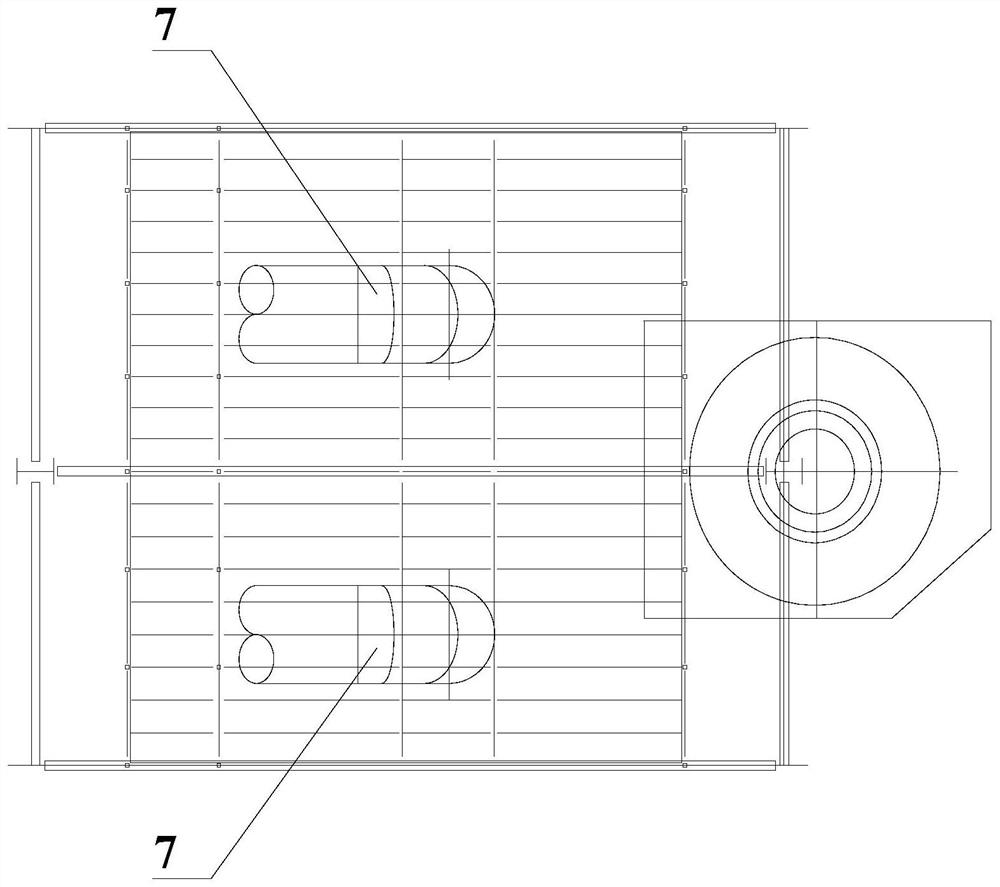

[0022] Such as figure 1 As shown, the embodiment of the present invention provides a dust removal hood, which includes two side sealing plates 10 , a top plate and a dust removal duct 7 . The two side sealing plates 10 have the same structure and are arranged in parallel and at intervals, and the upper end surface of each side sealing plate 10 is an arc surface. The roof cover is arranged on the two side sealing plates 10, the longitudinal section of the top plate is arc-shaped, the inner arc surface of the top plate is fixedly connected with the upper end surfaces of the two side sealing plates 10, and the top plate and the two side sealing plates 10 jointly form a A dust removal space with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com