Powder zincizing agent high in corrosion resistance

A powder galvanizing, high corrosion resistance technology, applied in the field of steel corrosion resistance, can solve problems such as the ability to reach 1000 hours and the difficulty of forming high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

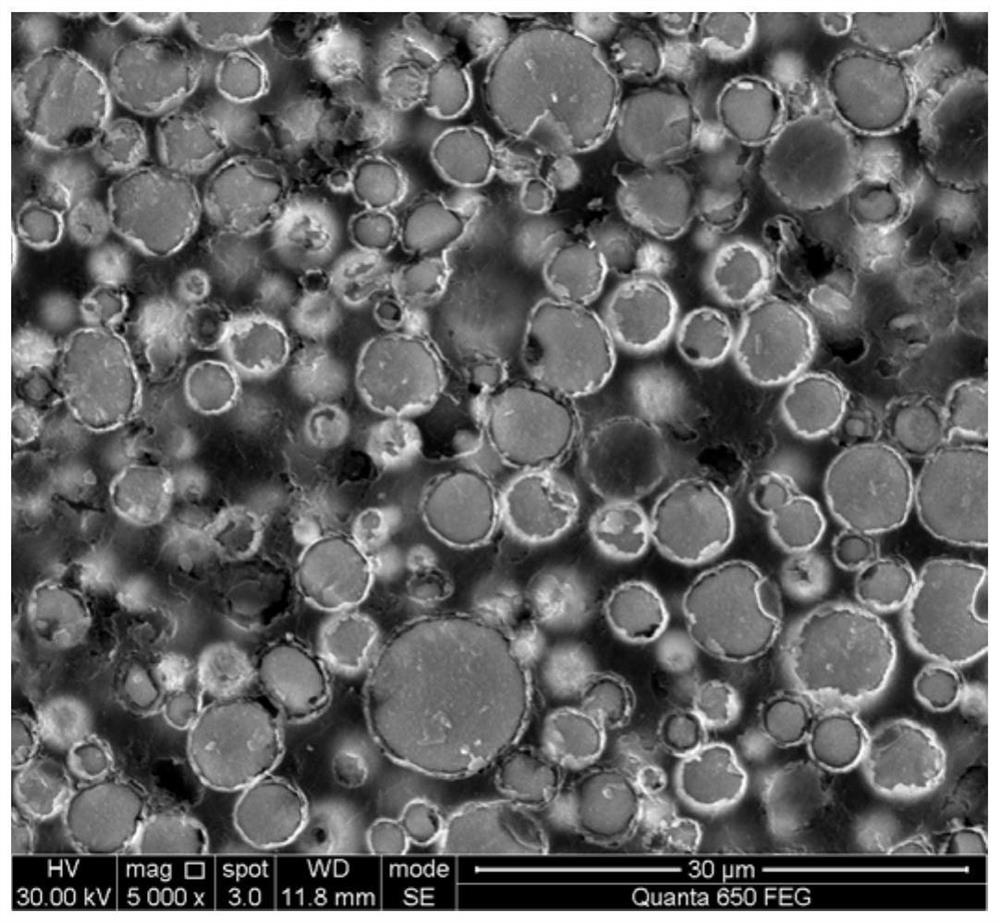

Image

Examples

Embodiment 1

[0030] Preferred embodiment 1 of the present invention provides a high-corrosion-resistant powder zinc-seeding agent, which is composed of raw materials in the following weight ratio: 40kg of zinc alloy powder, 80kg of ceramic powder, and 0.24kg of halide;

[0031] Wherein, the zinc alloy powder is composed of the following raw materials: zinc, magnesium, aluminum, phosphorus, and rare earth compounds, wherein the weight ratio of zinc, magnesium, aluminum, phosphorus, and rare earth compounds is 70:20:10:0.01:1.

[0032] The zinc alloy powder is obtained by first smelting and then powder-making (first, the zinc block is melted, then aluminum, magnesium, and rare earth compounds are added in sequence, and finally the phosphorus block is pressed into the molten zinc alloy; after smelting for a certain period of time, directly Atomized powder making), wherein the melting temperature is 600°C, and the melting time is 18 minutes.

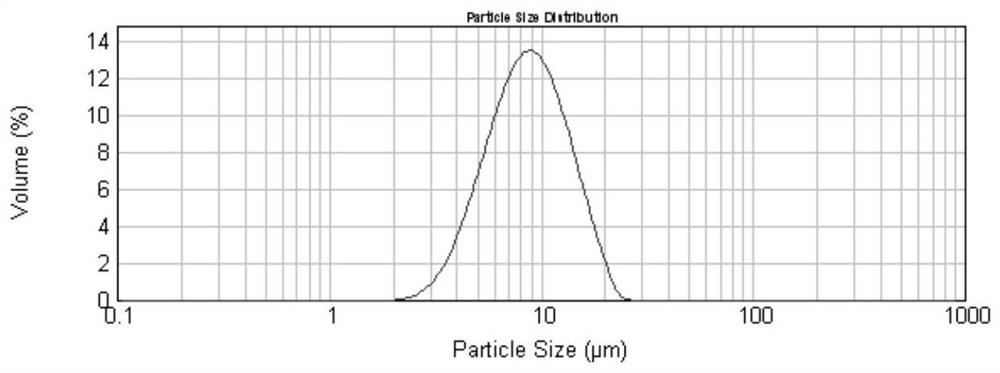

[0033] The average particle size of the zinc alloy...

Embodiment 2

[0039] Preferred embodiment 2 of the present invention provides a high-corrosion-resistant powder zinc-seeding agent, which is composed of raw materials in the following weight ratio: 50 kg of zinc alloy powder, 75 kg of ceramic powder, and 0.2 kg of halide;

[0040] Wherein, the zinc alloy powder is composed of the following raw materials: zinc, magnesium, aluminum, phosphorus, and rare earth compounds, wherein the weight ratio between zinc, magnesium, aluminum, phosphorus, and rare earth compounds is 78:15:5:0.1:0.2.

[0041] The zinc alloy powder is obtained by first smelting and then powder-making (first melting the zinc block, then adding aluminum, magnesium, and rare earth compounds in sequence, and finally pressing the phosphorus block into the molten zinc alloy; after smelting for a certain period of time, casting into ingots, and then mechanically crushed into powder), wherein the melting temperature is 800 ° C, and the melting time is 12 minutes.

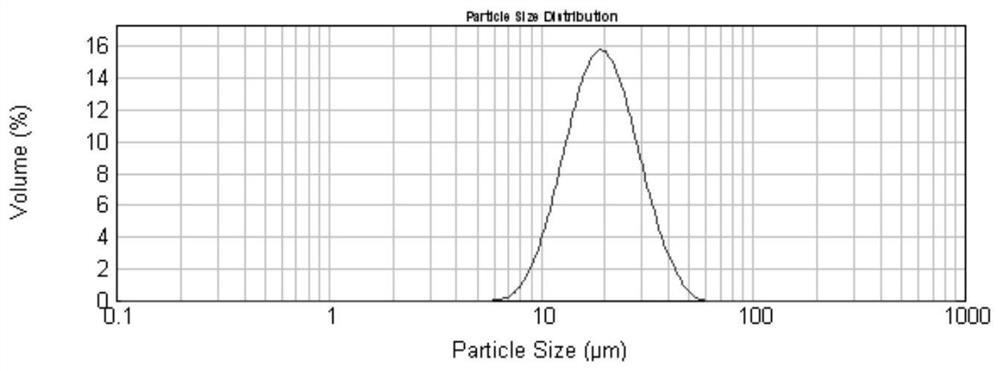

[0042] The powder ...

Embodiment 3

[0048] Preferred embodiment 3 of the present invention provides a high-corrosion-resistant powder zinc-seeding agent, which is composed of raw materials in the following weight ratio: 40kg of zinc alloy powder, 60kg of ceramic powder, and 0.2kg of halide;

[0049] Wherein, the zinc alloy powder is composed of the following raw materials: zinc, magnesium, aluminum, phosphorus, and rare earth compounds, wherein the weight ratio between zinc, magnesium, aluminum, phosphorus, and rare earth compounds is 72:25:6:0.2:1.

[0050] The zinc alloy powder is obtained by first smelting and then pulverizing (first, the zinc block is melted, then aluminum, magnesium, and rare earth compounds are added in sequence, and finally the phosphorus block is pressed into the molten zinc alloy; after smelting for a certain period of time, directly Atomized powder making), wherein the melting temperature is 650°C, and the melting time is 15 minutes.

[0051] The powder average particle size of the zin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com