Antibacterial vinylon, hemp and cotton blended yarn and production method thereof

A production method, cotton blending technology, applied in the field of antibacterial vinylon, cotton blended yarn and its production, and hemp, which can solve the problems of limited application fields, bamboo and hemp yarn strength, wear resistance and spinnability are not ideal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

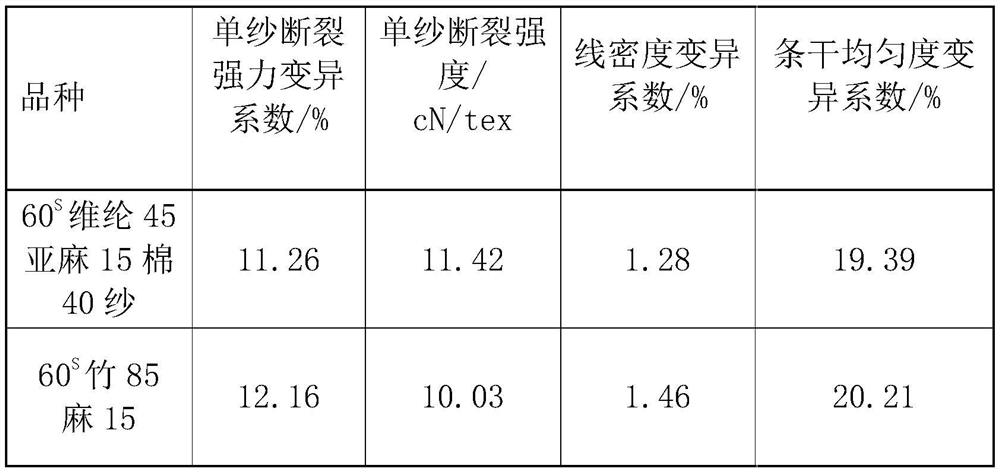

[0028] Embodiment 1: spinning 60 S Vinylon 45% Linen 15% Cotton 40% Compact Spun Combed Yarn

[0029] According to product requirements, select suitable flax fibers, degumming with biological enzymes, add oil to the wet, and carry out health preservation in a hemp warehouse with a temperature of 40-50°C and a relative humidity of 85-90%, so that the moisture regain of the dry flax can reach 14%. After the warehouse, the flax is cut off to a length of 50-60 mm. After being loosened by an opener, it is combed once by a carding machine. The combed flax fiber is packed with an appropriate amount of emulsified oil for later use; the fiber The moisture regain is maintained at 13%, and the quality indicators of the hemp fibers are as follows: the average length is controlled at 30 mm, the length unevenness is ≤15%, the hemp grains are ≤40 grains / gram, and the fiber count is 3500.

[0030] Based on 100% of the weight, a certain amount of cotton fiber and flax fiber is weighed in a ra...

Embodiment 2

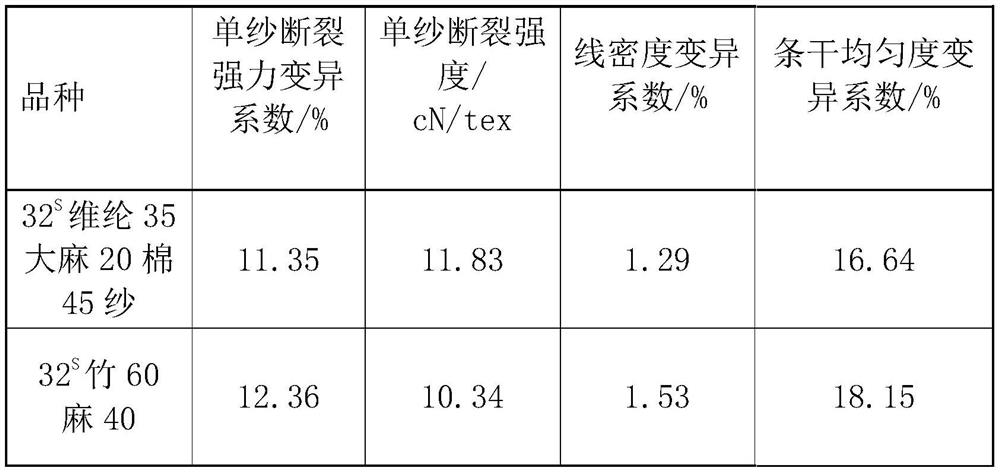

[0039] Example 2: Spinning 32 S Vinylon 40% Hemp 20% Cotton 40% Compact Spun Combed Yarn

[0040] According to product requirements, select the appropriate hemp fiber, add oil to the wet after degumming with biological enzymes, and carry out health preservation in a hemp warehouse with a temperature of 40-50°C and a relative humidity of 85-90%, so that the moisture regain of the dry hemp can reach 15%. After the warehouse, the hemp is cut off to a length of 50 mm. After being loosened by an opener, it is combed once by a carding machine. The combed hemp fiber is added with an appropriate amount of emulsified oil and packed for later use; to make the fiber moisture regain Keep it at 14%, and the quality index of the hemp fiber is as follows: the average length is controlled at 32 mm, the length unevenness is ≤17%, the hemp grains are ≤45 grains / gram, and the fiber count is about 3200.

[0041]Based on 100% by weight, a certain amount of cotton fiber and hemp fiber is weighed i...

Embodiment 3

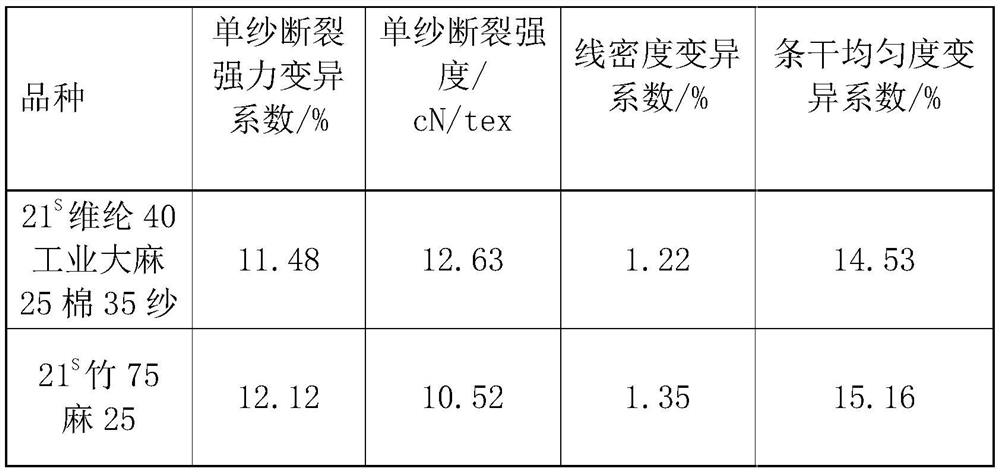

[0050] Example 3: Spinning 21 S Vinylon 40% Hemp 25% Cotton 35% Combed Yarn

[0051] According to the product requirements, select the appropriate industrial hemp fiber, add oil to the wet after degumming with biological enzymes, and carry out health preservation in a hemp warehouse with a temperature of 40-50°C and a relative humidity of 85-90%, so that the moisture regain of the dry hemp can reach 13%. After leaving the warehouse, cut off the dry hemp of industrial hemp to a length of 60 mm. After being loosened by an opener, it is combed once by a carding machine. The combed industrial hemp fiber is added with an appropriate amount of emulsified oil and packed for later use; The fiber moisture regain is kept at 12%, and the quality indicators of the hemp fiber are: the average length is controlled at 28mm, the length unevenness is ≤20%, the hemp grains are ≤50 grains / g, and the fiber count is about 2,800.

[0052] Based on 100% by weight, a certain amount of cotton fiber a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com