Planet axial movement milling and grinding overlapped quadrangular head mechanism

A technology of axial movement and grinding mechanism, which is applied in the field of milling and planing machinery, can solve the problems of low road surface flatness and inconvenient maintenance, and achieve the effect of high road surface flatness, fine milling lines, and good marketing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

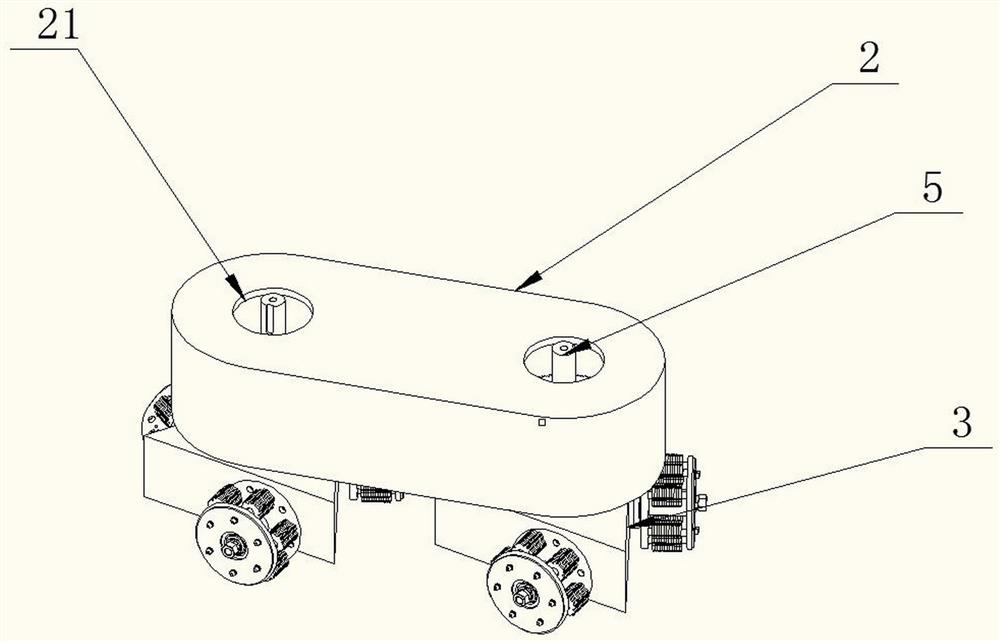

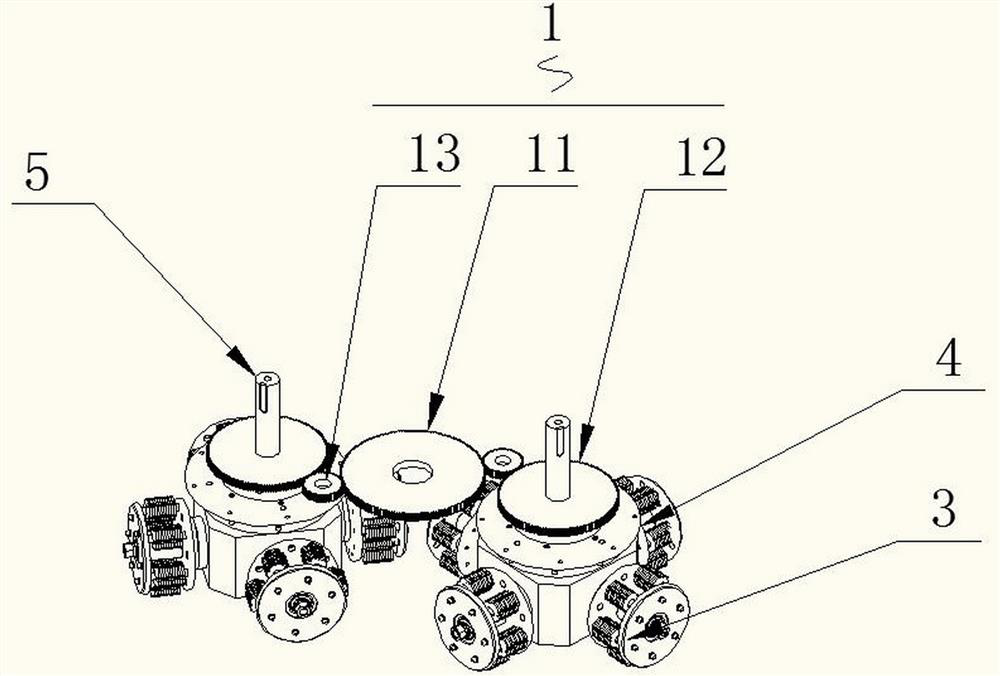

[0031] Embodiment one: if Figure 1-2 As shown, when the number of the transmission shaft 5 is two, the left and right sides of the upper end surface of the housing 2 and the left and right sides of the lower end surface are respectively symmetrically provided with round holes 21, and the bottom of one transmission shaft 5 passes through the housing 2 The left side of the upper end surface and the corresponding circular hole 21 on the left side of the lower end surface, the bottom of the other transmission shaft 5 passes through the corresponding circular hole 21 on the right side of the upper end surface of the housing 2 and the right side of the lower end surface, and the transmission mechanism 1 includes Main gear 11, driven gear 12 and transition gear 13, two described driven gears 12 are sleeved on two transmission shafts 5 respectively, described main gear 11 is positioned at the center of two driven gears, and described driven The gear 12 is connected to the main gear 1...

Embodiment 2

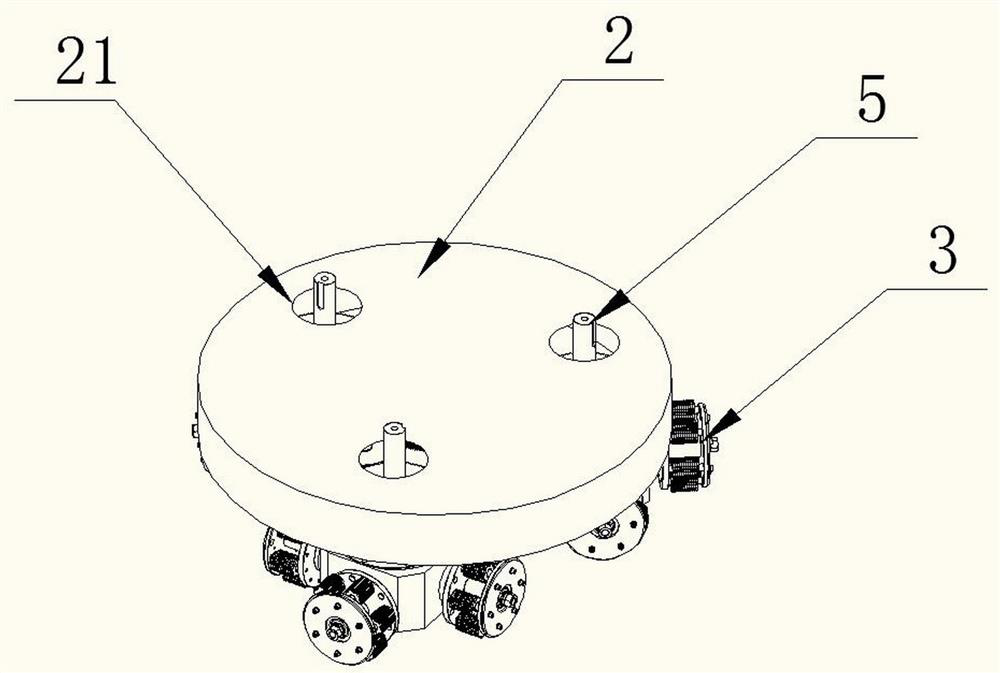

[0032] Embodiment two: if Figure 3-4 As shown, when the number of the transmission shaft 5 is three, the upper end surface of the housing 2 is provided with circular holes 21 along the three vertices of the equilateral triangle, and the lower end surface of the housing 2 is arranged along the three vertices of the equilateral triangle. A round hole 21 is arranged at the first apex, and the bottoms of the three transmission shafts 5 respectively pass through the round holes 21 corresponding to the upper and lower end surfaces of the housing 2. The two driven gears 12 are respectively sleeved on the three transmission shafts 5, the main gear 11 is located at the center of an equilateral triangle, and the driven gear 12 and the main gear 11 are connected by a transition gear 13. The transition gear 13 meshes with the driven gear 12 and the main gear 11 respectively.

Embodiment 3

[0033] Embodiment 3: When the number of the transmission shaft 5 is more than four, the upper end surface of the housing 2 is provided with round holes 21 along the corners of the regular polygon, and the lower end surface of the housing 2 is provided along the corners of the regular polygon. There are round holes 21, and the bottom of the transmission shaft 5 respectively passes through the round holes 21 corresponding to the upper and lower end faces of the housing 2. The transmission mechanism 1 includes a main gear 11, a driven gear 12 and a transition gear 13. A plurality of the The driven gear 12 is respectively sleeved on a plurality of transmission shafts 5, and the main gear 11 is located at the center of the regular polygon. The driven gear 12 is connected with the main gear 11 by a transition gear 13, and the transition gear 13 is It meshes with the driven gear 12 and the main gear 11.

[0034] Such as Figure 5 As shown, the base 4 includes a flange one 41, a flan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com