Coil Spring Overrunning Clutch

An overrunning clutch and coil spring technology, applied in the field of clutches, can solve the problems affecting the strength and service life of the clutch body, the rollers cannot move according to the predetermined trajectory, the rollers cannot fully reach the designed stroke, etc., and achieves good heat dissipation and lubrication effects. , The effect of improving processing technology and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

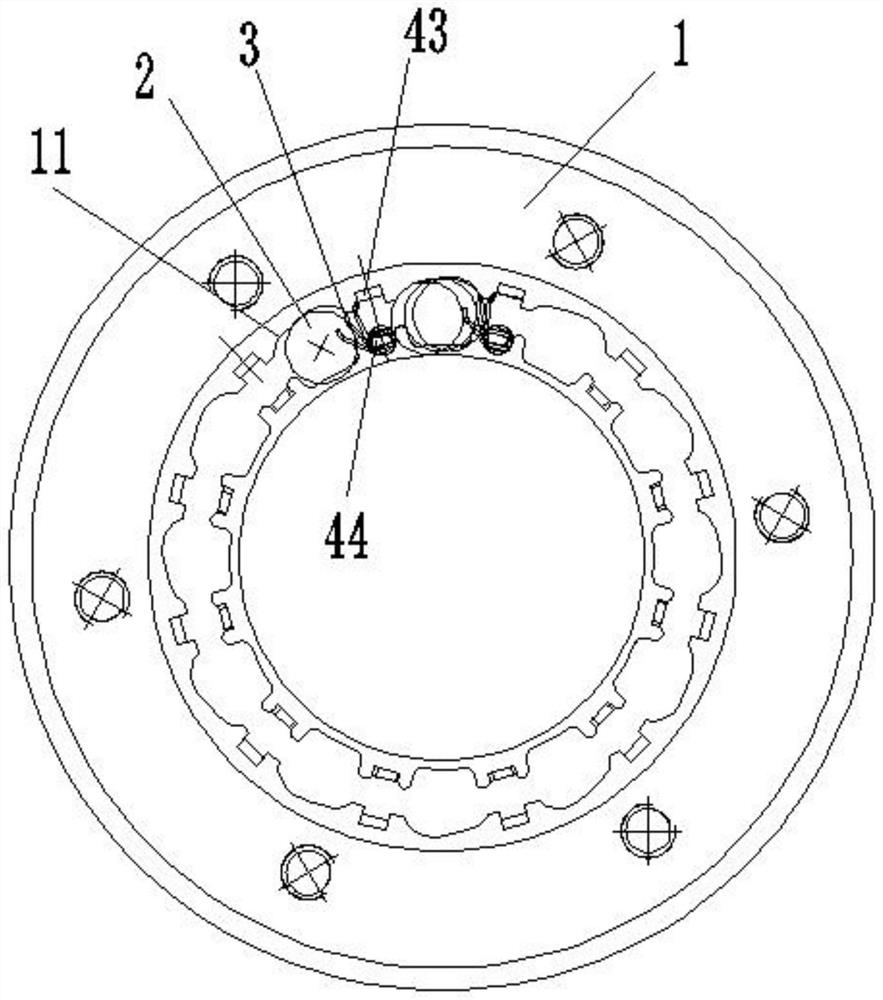

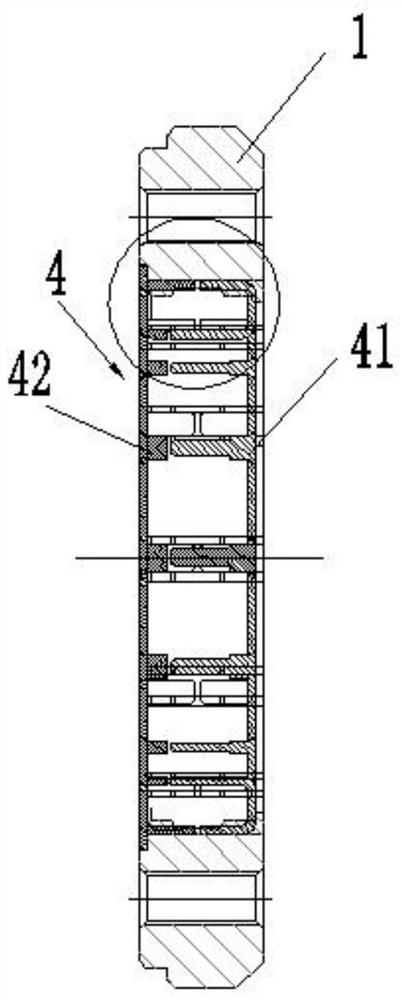

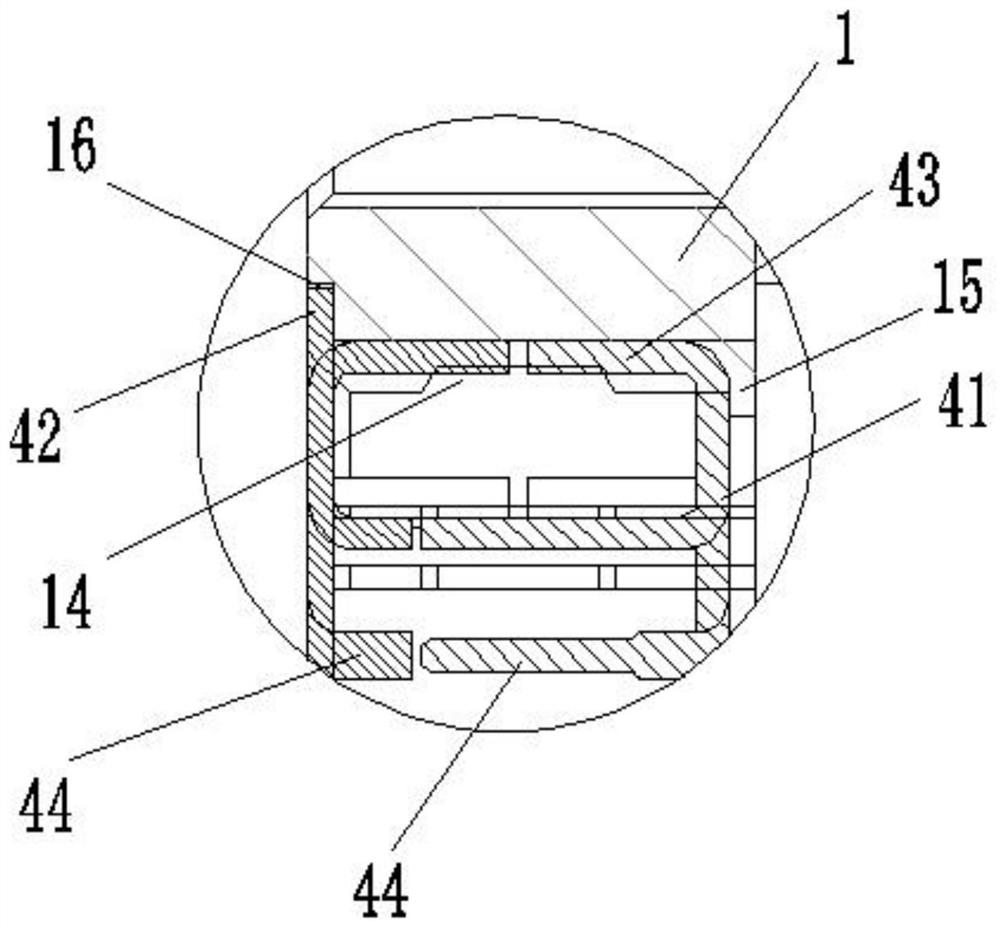

[0032] like Figure 1 to Figure 5 As shown, a spiral spring type overrunning clutch includes a body 1 and a roller 2, the body 1 is annular, and a roller profile groove 11 is provided on the inner peripheral wall of the body 1, and the roller profile groove 11 is placed in the There are rollers 2, and the number of the rollers 2 in this embodiment is 12, so that the clutch has excellent bearing capacity and better dynamic balance. A coiled coil spring 3 is arranged between the rollers 2 . The coil springs 3 are mounted on a bead holder 4 fixed to the body 1 , and the tail end of each coil spring 3 abuts against the roller 2 on the front side thereof On the other hand, the tail portion of the coil spring 3 exerts a spring force on the rollers 2 so that each roller 2 abuts against the mounting portion of the coil spring 3 on the front side thereof when the roller 2 is in a non-working state. like figure 1 , figure 2 , Figures 6 to 9 As shown, the bead holder 4 includes a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com