Water cooling device for safe production of aluminum products

A technology for safe production and water-cooling devices, which is applied in household refrigeration devices, cooling fluid circulation devices, applications, etc., and can solve the problem of not being able to quickly remove solid impurities in the cooling liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

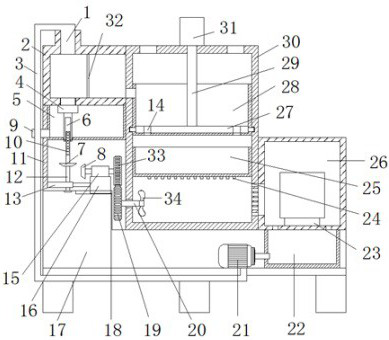

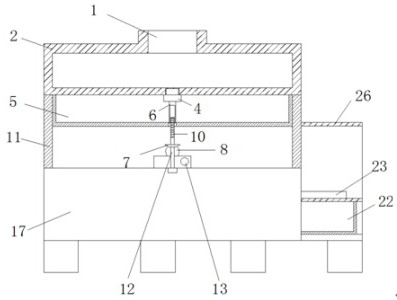

[0022] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

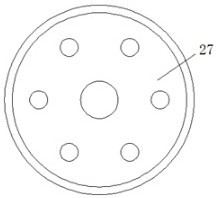

[0023] Reference Figure 1-3 , A water cooling device for the safe production of aluminum products, comprising a base 17, a power box 11 is fixedly connected to the top of the left side of the base 17, a first sliding block 16 is slidably connected to the top of the base 17, and the top of the first sliding block 16 The dual-axis motor 15 is fixedly connected. The left output shaft of the dual-axis motor 15 is fixedly sleeved with a first bevel gear 8, and the right end output shaft of the dual-axis motor 15 is fixedly sleeved with a first gear 33. A hydraulic cylinder 13 is fixedly connected to the side, a second rotating shaft 12 rotatabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com