A non-contact torsional vibration measurement method based on machine vision

A non-contact, measurement method technology, applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of complex and expensive non-contact measuring devices, high application cost, single measuring point, etc., and achieve test results Fast and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

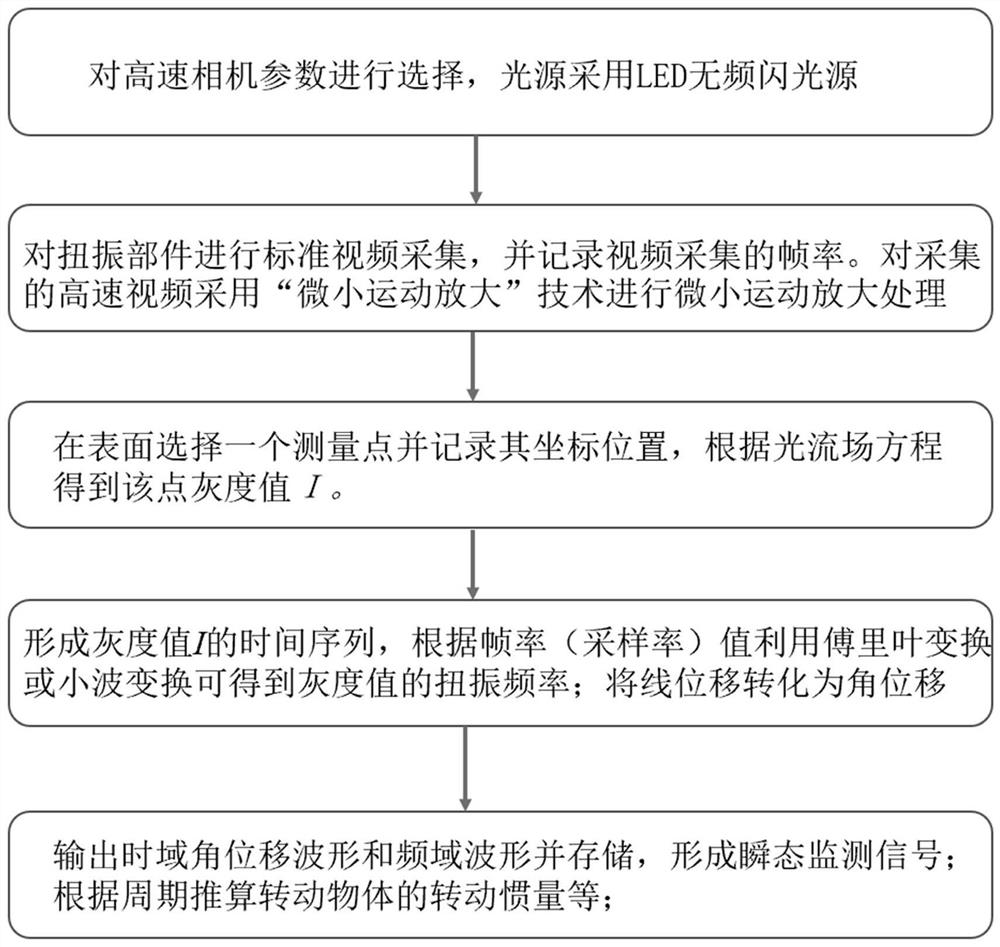

Method used

Image

Examples

Embodiment

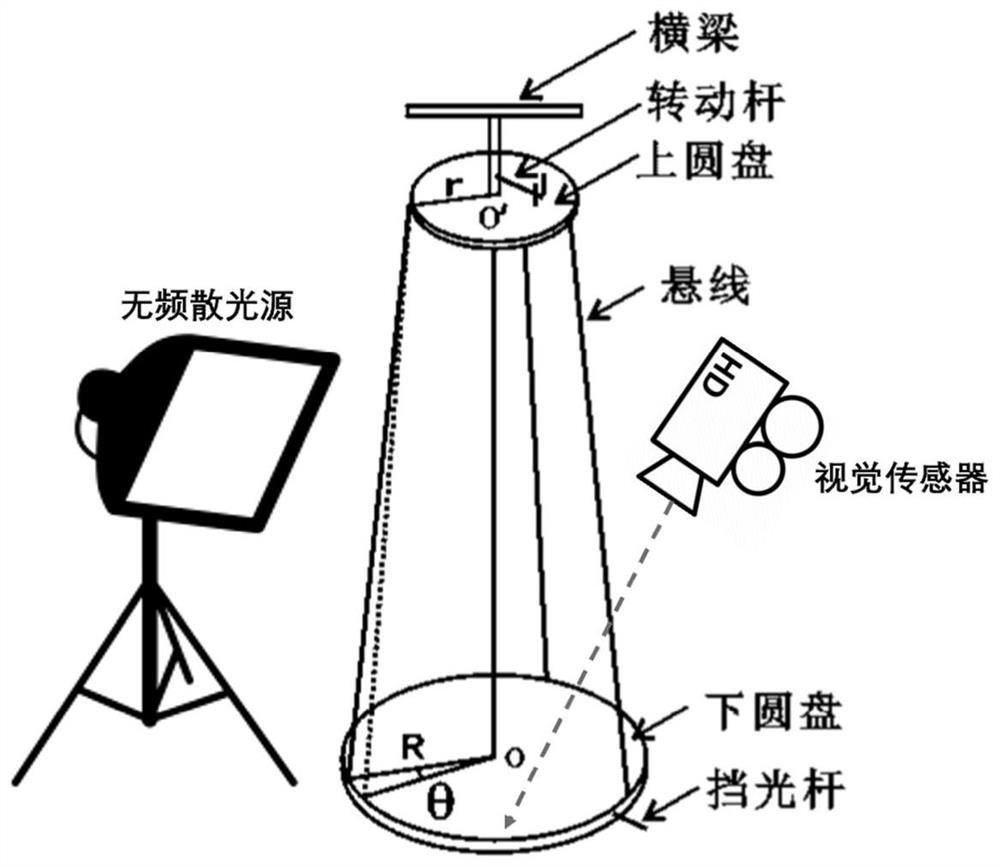

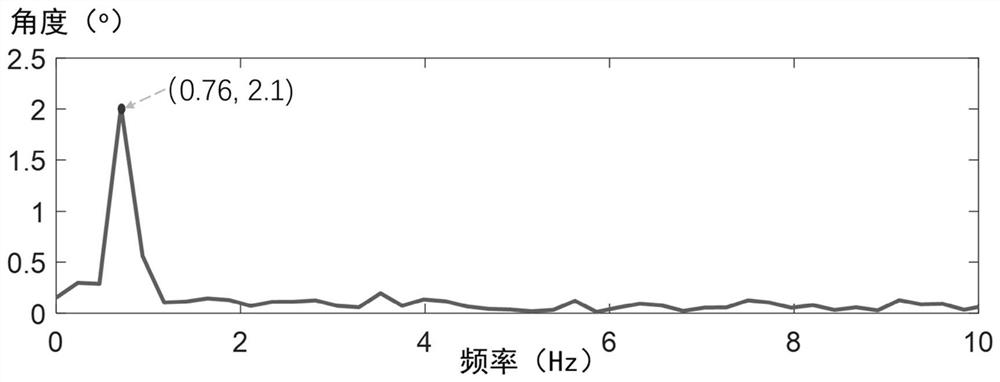

[0056] figure 2 It is a three-wire pendulum test scene diagram in the embodiment of the present invention. The main test object is a standard three-wire pendulum, and the turntable is a three-wire pendulum experimental standard turntable. The purpose of using this experimental sample is to verify the accuracy of the measurement method proposed by the present invention. The parameters of the three-wire pendulum are shown in Table 1. It can be seen that the test device of the present invention is much simpler than the traditional sensor device, and does not need expensive data acquisition equipment, acceleration sensors, laser vibrometers and the like. When the rotation angle of the turntable is less than 5°, the small displacement assumption of the present invention is met. Firstly, the three-wire pendulum was excited with a small rotation angle, and the torsional vibration of the turntable was recorded by the method, and the time was about 10 seconds. After micro-motion amp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com