Large-scale wind driven generator shafting rotating torque measuring device and measuring method

A wind power generator and rotational torque technology, applied in the direction of measuring devices, torque measurement, power measurement, etc., can solve the problems of inaccurate measurement of tension value, inability to guarantee uniform rotation, inaccurate measurement of torque value, etc., to achieve convenient Worker operation, simple structure, and the effect of improving assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further illustrate the technical means adopted by the present invention and the technical effects achieved, the following will be described in detail in conjunction with the accompanying drawings and embodiments.

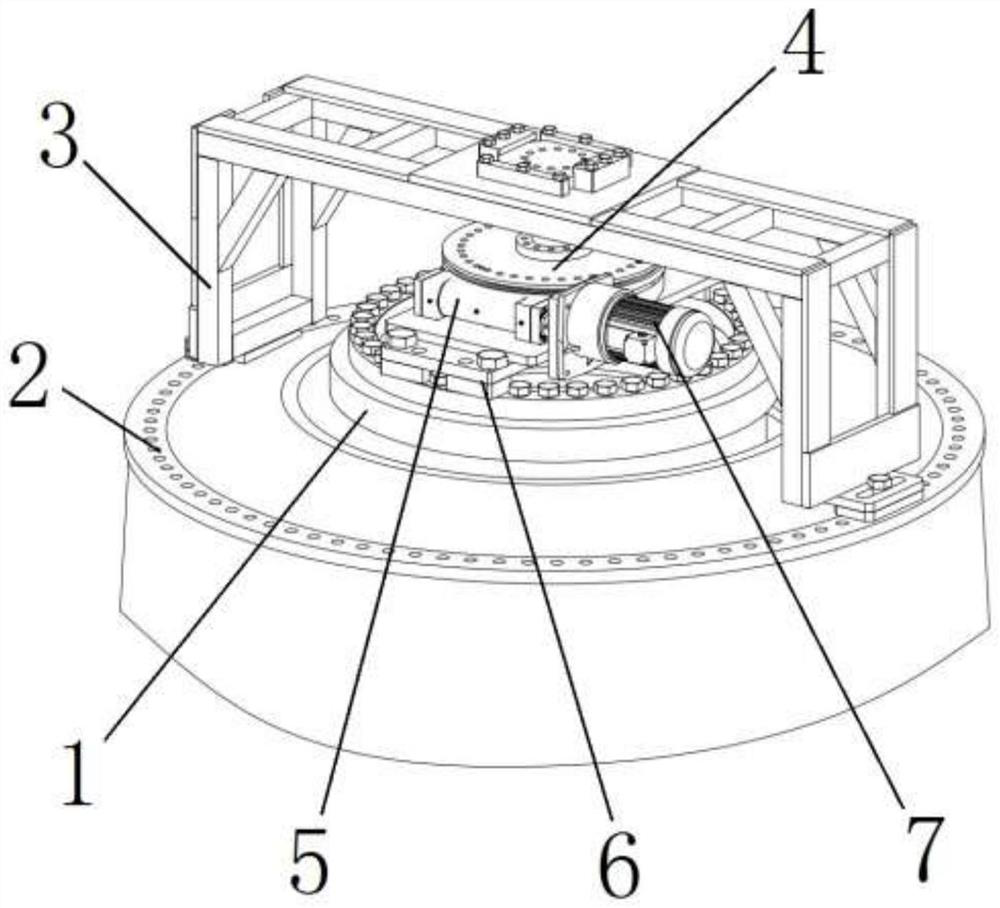

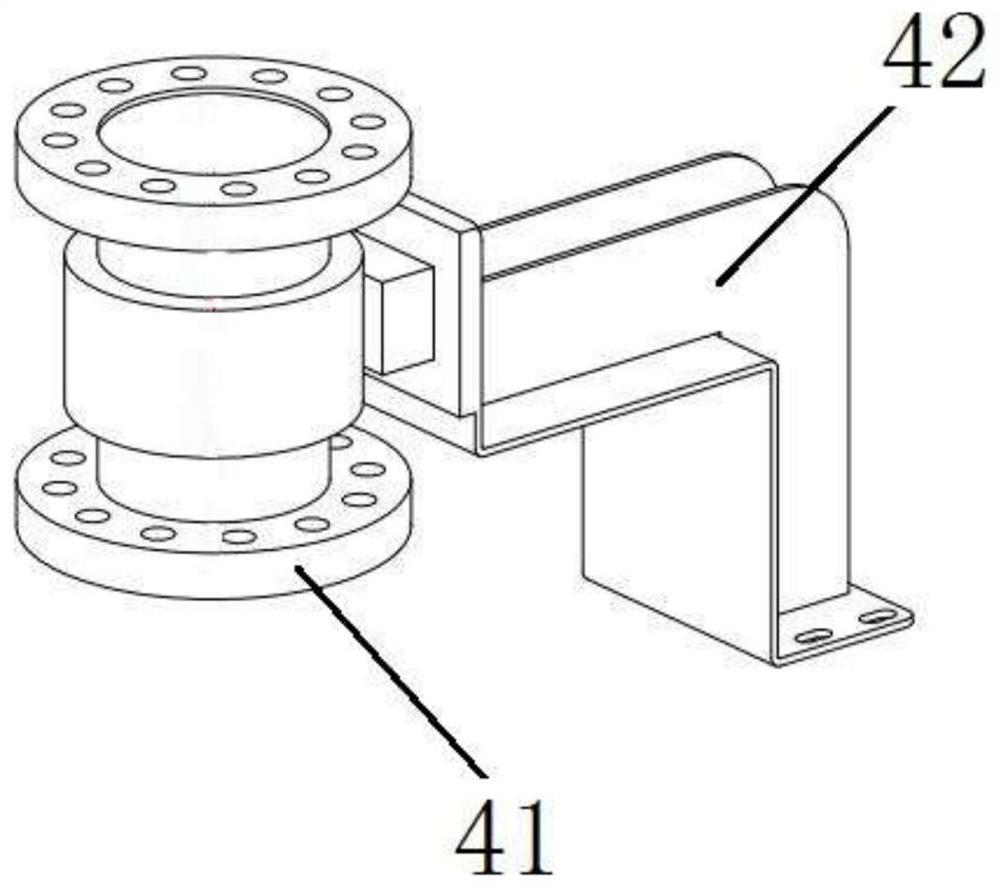

[0027] refer to figure 1 and figure 2 , the present invention provides a large-scale wind power generator shafting rotational torque measuring device, which is used for a shafting system consisting of a fixed shaft 1 and a moving shaft 2, the device includes a moving shaft connecting plate 3, a torque sensor 4, and a slewing bearing 5 , fixed axis connecting plate 6 and drive motor 7.

[0028] The fixed shaft connecting plate 6 is fixed on the fixed shaft 1 . The slewing bearing 5 is fixed above the fixed shaft connecting plate 6 . The drive motor 7 is arranged on the side of the slewing bearing 5 , and the drive motor 7 is connected to the slewing bearing 5 , and the drive motor 7 drives the slewing bearing 5 to rotate. The moving shaft conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com