Cyclic shear test device under constant normal stiffness condition and application method thereof

A technology of normal stiffness and shear test, which is applied in the direction of testing material strength, measuring device, strength characteristics, etc. by applying stable shear force, which can solve the problems of inability to consider complex confining pressure conditions and inability to simulate well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

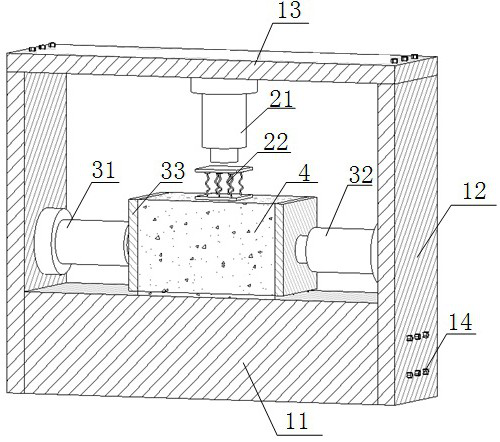

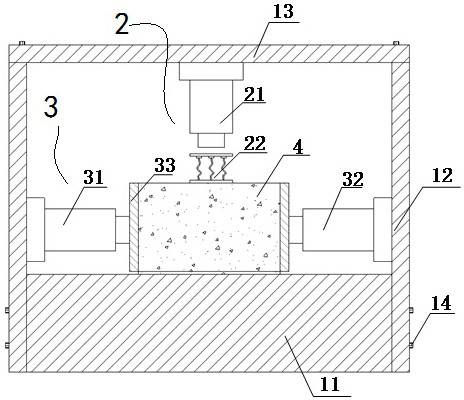

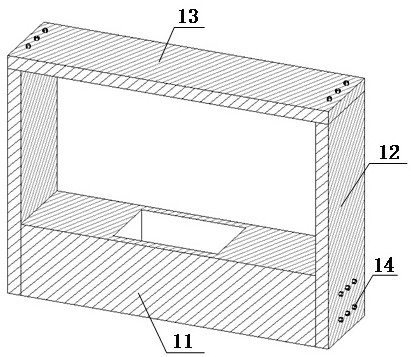

[0023] Example: such as Figure 1~8 As shown, a cyclic shear test device under constant normal stiffness conditions is provided, including a reaction force frame system 1, a shear force application system 3, a normal loading system 2 and an anchored fractured rock mass specimen 4;

[0024] The shear force application system 3 includes loading pads 33 located on both sides of the anchored fractured rock mass specimen, shearing hydraulic cylinders located on the sides of the loading pads, and hydraulic oil for supplying the two shearing hydraulic cylinders. The shearing force servo oil source; the shearing hydraulic cylinder is fixed inside the square loading plate.

[0025] The normal loading system 2 includes a normal hydraulic cylinder 21, an axial pressure servo oil source and a spring backing plate 22 for supplying oil to the found hydraulic cylinder, the normal hydraulic cylinder is located above the spring backing plate, and the spring The backing plate is located above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com