Generator bridging strand brazing ultrasonic detection method

A detection method, ultrasonic technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, use sound waves/ultrasonic waves/infrasonic waves for material analysis, and measurement devices. It can solve the problems of large differences in grain size, low bottom echo, Low signal-to-noise ratio and other problems, to achieve good social and economic benefits, reduced sound path attenuation, and fast detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

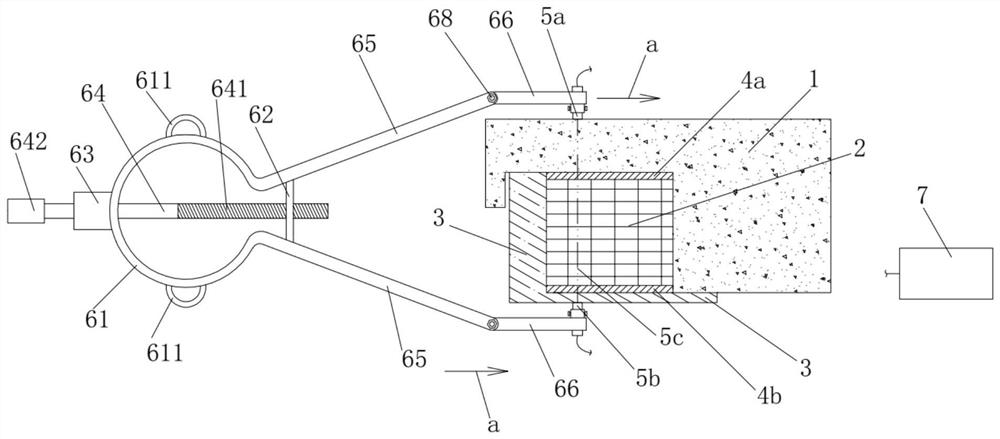

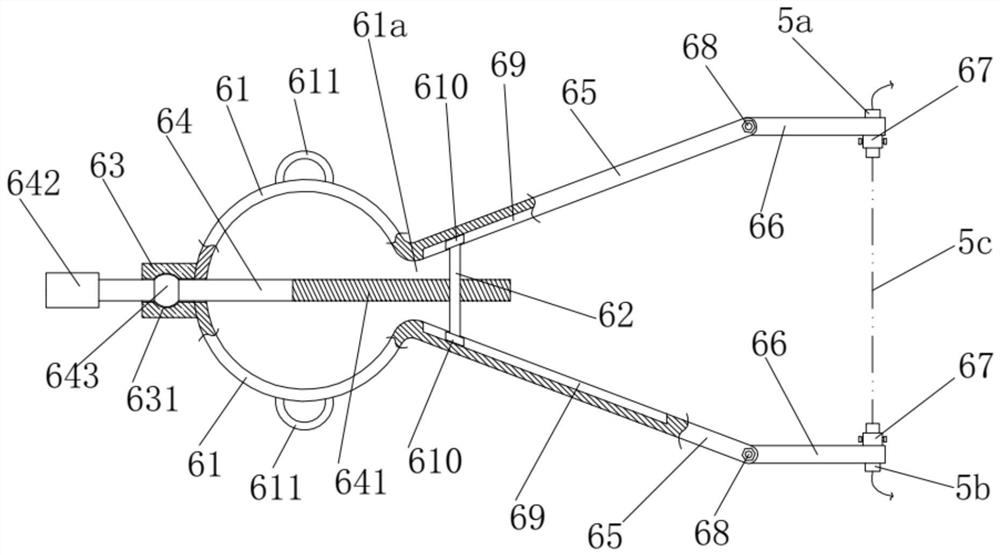

[0026] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

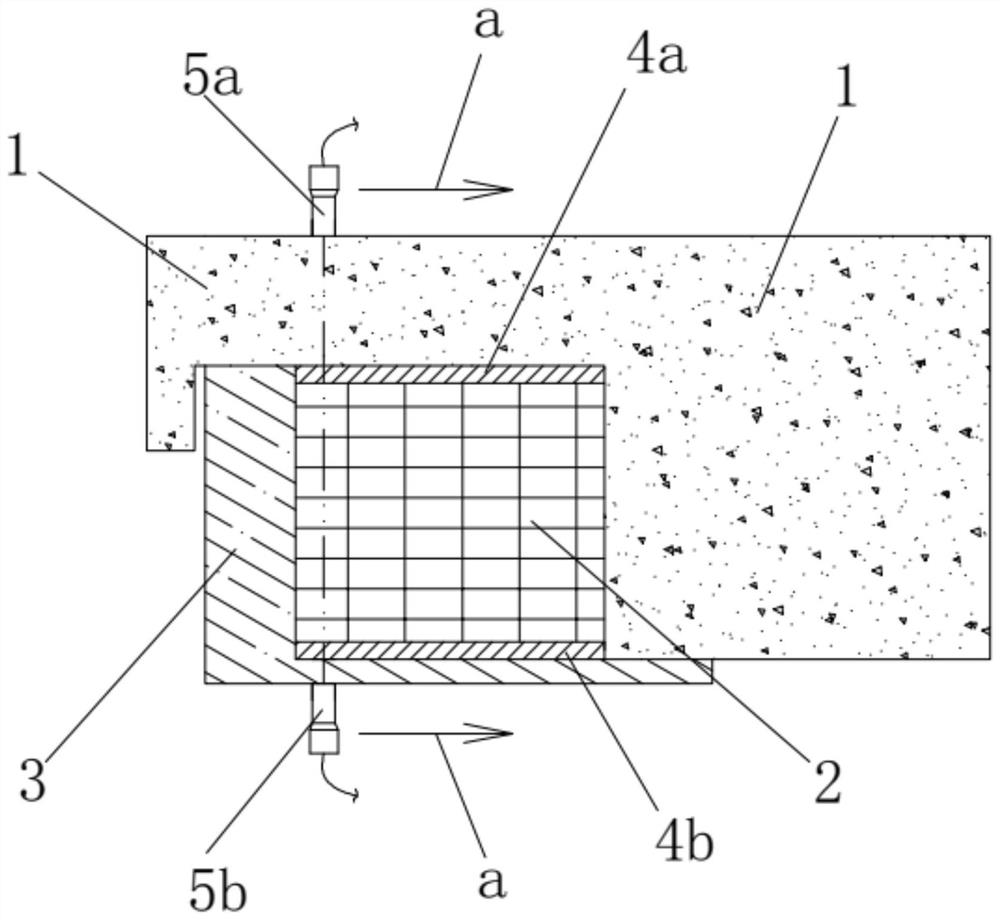

[0027] Depend on Figure 1-3 Provided, the present invention a kind of ultrasonic detection method of brazing of generator bridge strand, comprises water box cover 1, bridge strand 2 and L-shaped pressing plate 3, is provided with between water box cover 1 and bridge strand 2 The first bridging strand brazing layer 4a, the second bridging strand brazing layer 4b is arranged between the bridging strand 2 and the L-shaped pressing plate 3, the method also includes an ultrasonic detector and two ultrasonic waves connected to it A longitudinal wave transducer, the two ultrasonic longitudinal wave transducers are respectively a transmitting transducer 5a and a receiving transducer 5b;

[0028] The transmitting transducer 5a is used to transmit pulsed ultrasonic waves to the object to be inspected, and the pulsed ultrasonic w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com