Detection method of box-type transformer and transformer

A box-type transformer and detection method technology, applied in transformer testing, transformer/inductance parts, instruments, etc., can solve problems such as high installation cost, inconvenient life, and difficult installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

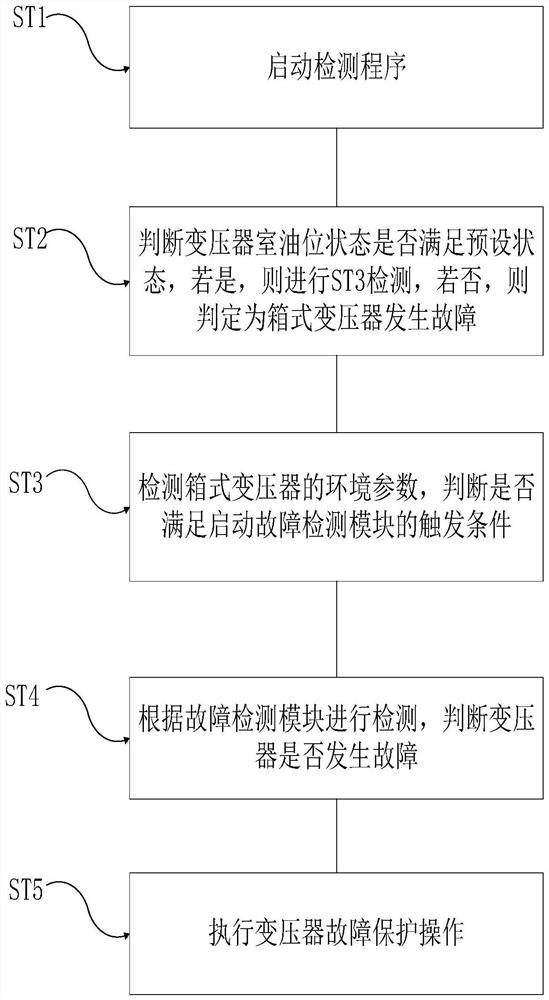

[0093] Embodiment 1, the present invention discloses a detection method of a box-type transformer. The box-type transformer includes a high-voltage room, a transformer room and a low-voltage room. The detection method includes the following steps:

[0094] ST1: Start the detection program;

[0095] ST2: Determine whether the oil level in the transformer room satisfies the preset state, if yes, perform ST3 detection, if not, determine that the box-type transformer is faulty;

[0096] ST3: Detect the environmental parameters of the box-type transformer, and judge whether the trigger condition for starting the fault detection module is met;

[0097] ST4: Detect according to the fault detection module to determine whether the transformer is faulty;

[0098] ST5: Execute transformer fault protection operation.

[0099] The box-type transformer includes a base on which three boxes that can be combined and spliced and fixed are arranged. The three boxes are separately arranged as...

Embodiment 2

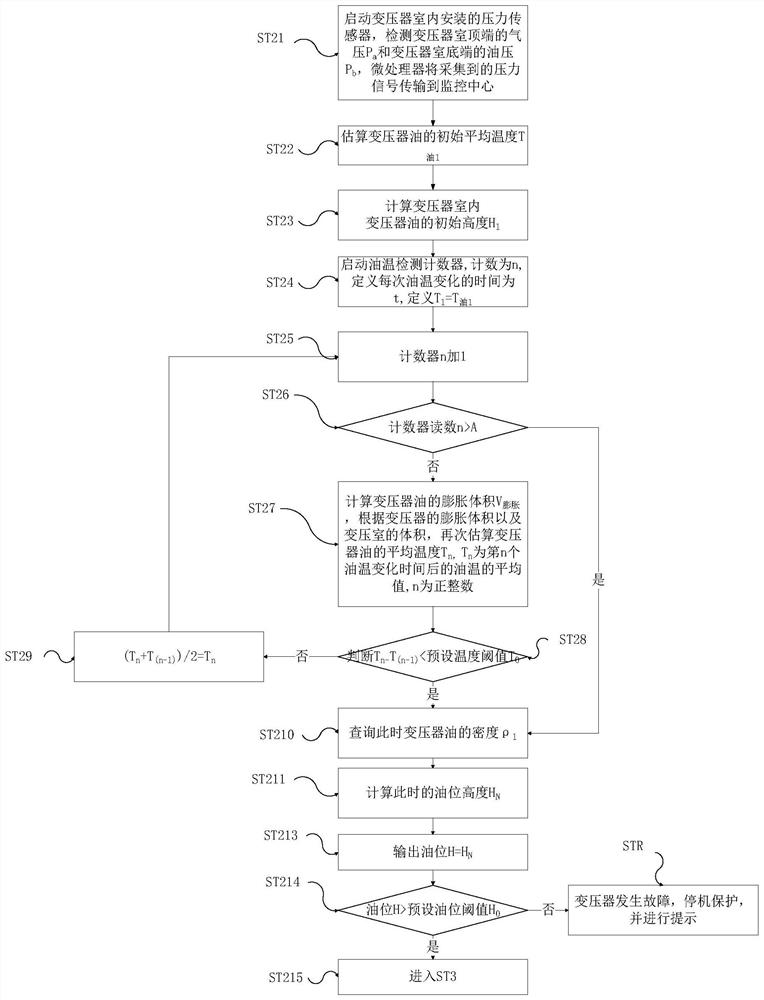

[0102] like figure 2 As shown, in ST2, the following detection steps are included:

[0103] ST21: Start the pressure sensor installed in the transformer room to detect the air pressure Pa at the top of the transformer room and the oil pressure P at the bottom of the transformer room b , the microprocessor transmits the collected pressure signal to the monitoring center;

[0104] ST22: Estimate the initial average temperature T of the transformer oil 油1 ;

[0105] ST23: Calculate the initial height H of the transformer oil in the transformer room 1 ;

[0106] ST24: Start the oil temperature detection counter, the count is n, define the time for each estimated oil temperature change as t, define T 1 =T 油1 ;

[0107] ST25: add 1 to the counter n;

[0108] ST26: Determine whether the counter reading n>A, where A is greater than 15; if yes, enter ST210; if not, enter ST27;

[0109] ST27: Calculate the expansion volume V of transformer oil 膨胀 , according to the expansion ...

Embodiment 3

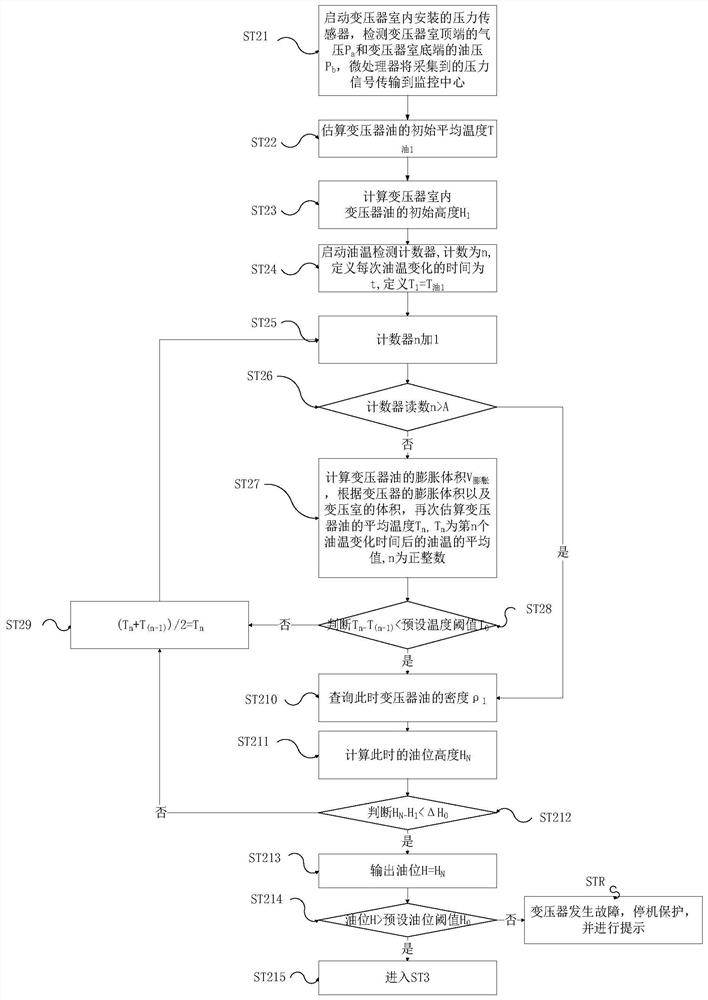

[0121] like image 3 As shown, in ST2, the following detection steps are included:

[0122] ST21: Start the pressure sensor installed in the transformer room to detect the air pressure P at the top of the transformer room a and the oil pressure P at the bottom of the transformer chamber b , the microprocessor transmits the collected pressure signal to the monitoring center;

[0123] ST22: Estimate the initial average temperature T of the transformer oil 油1 ;

[0124] ST23: Calculate the initial height H of the transformer oil in the transformer room 1 ;

[0125] ST24: Start the oil temperature detection counter, the count is n, define the time for each estimated oil temperature change as t, define T 1 =T 油1 ;

[0126] ST25: add 1 to the counter n;

[0127] ST26: Determine whether the counter reading n>A, where A is greater than 15; if yes, enter ST210; if not, enter ST27;

[0128] ST27: Calculate the expansion volume V of transformer oil 膨胀 , according to the expans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com