Non-breathable explosion-proof membrane, preparation method and power battery explosion-proof valve

A gas-permeable, explosion-proof film technology, applied in the direction of batteries, battery pack components, circuits, etc., can solve the problems of long-term oil and water resistance, dust resistance, high temperature resistance, chemical corrosion resistance, flame retardancy and electrical insulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

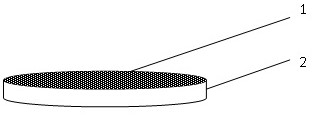

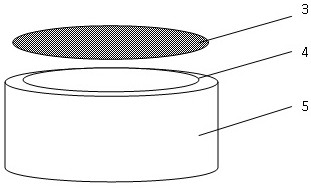

[0022] A non-breathable explosion-proof membrane 3 includes: a non-breathable explosion-proof membrane 2 and an oil- and water-repellent functional coating 1, and the surface of the non-breathable explosion-proof membrane is provided with an oil- and water-repellent functional coating.

[0023] In the embodiment, the non-breathable explosion-proof film 3 precisely controls the critical value of the burst pressure to 25 kPa by controlling the thickness of the non-breathable explosion-proof film 2 to 10 μm and the mechanical strength to 15 MPa.

[0024] The present invention also relates to the preparation process of non-breathable explosion-proof film 2: polytetrafluoroethylene (PTFE) suspension resin or / and modifier is used to mold into a billet, sintered in a sintering furnace at a high temperature of 385°C, and then cooled to form a rod. A non-breathable explosion-proof film 2 of 10 μm is made by turning process and calendering process.

[0025] In the embodiment, the surfac...

Embodiment 2

[0033] A non-breathable explosion-proof membrane 3, comprising: a non-breathable explosion-proof membrane 2 and a surface oil-repellent and water-repellent functional coating 1.

[0034] In the embodiment, the non-breathable explosion-proof film 3 precisely controls the critical value of the burst pressure to 30 kPa by controlling the thickness of the non-breathable explosion-proof film 2 to 12 μm and the mechanical strength to 20 MPa.

[0035] The present invention also relates to the preparation process of the non-breathable explosion-proof film 2: polytetrafluoroethylene (PTFE) suspending resin or / and modifier is used to mold into a billet, sintered in a sintering furnace at a high temperature of 395°C, and then cooled to form a rod. The non-breathable explosion-proof film 2 of 12 μm is made by turning process and calendering process.

[0036] In the embodiment, the surface of the non-breathable explosion-proof membrane 2 is activated, and the surface of the explosion-proof...

Embodiment 3

[0044] A non-breathable explosion-proof membrane 3 includes: a non-breathable explosion-proof membrane 2 and an oil- and water-repellent functional coating 1, and the surface of the non-breathable explosion-proof membrane is provided with an oil- and water-repellent functional coating.

[0045] In the embodiment, the non-breathable explosion-proof film 3 precisely controls the critical value of the burst pressure to 35 kPa by controlling the thickness of the non-breathable explosion-proof film 2 to 30 μm and the mechanical strength to 25 MPa.

[0046] The present invention also relates to the preparation process of non-breathable explosion-proof film 2: polytetrafluoroethylene (PTFE) suspension resin or / and modifier is used to mold into a billet, sintered in a sintering furnace at a high temperature of 385°C, and then cooled to form a rod. A non-breathable explosion-proof film 2 of 30 μm is made by turning process and calendering process.

[0047] In the embodiment, the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com