Color-changing bionic automobile seat cover material and manufacturing method thereof

A manufacturing method and technology of automobile chairs, which are applied in the field of seat cover materials, can solve the problems of inability to resist static electricity and antibacterial effects, achieve good antistatic ability, avoid harming the human body, and have low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

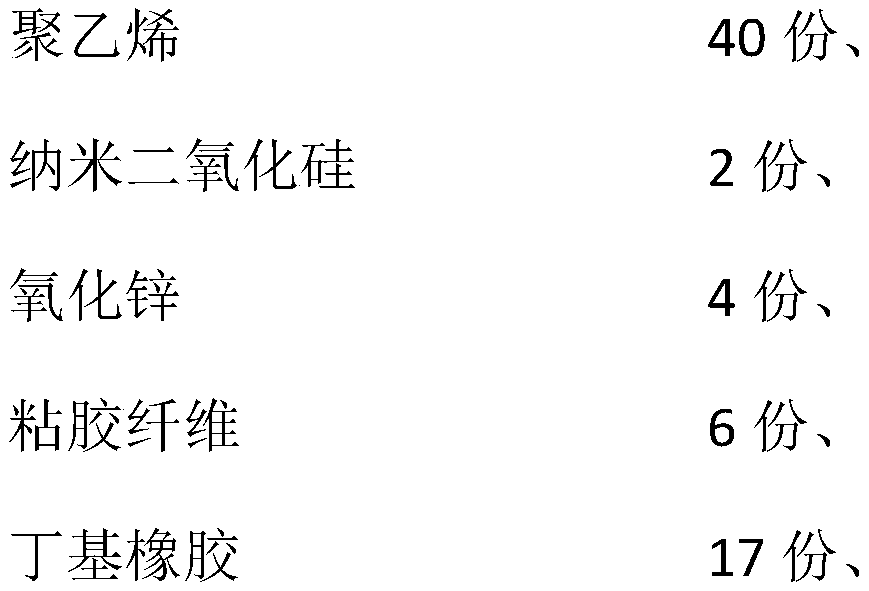

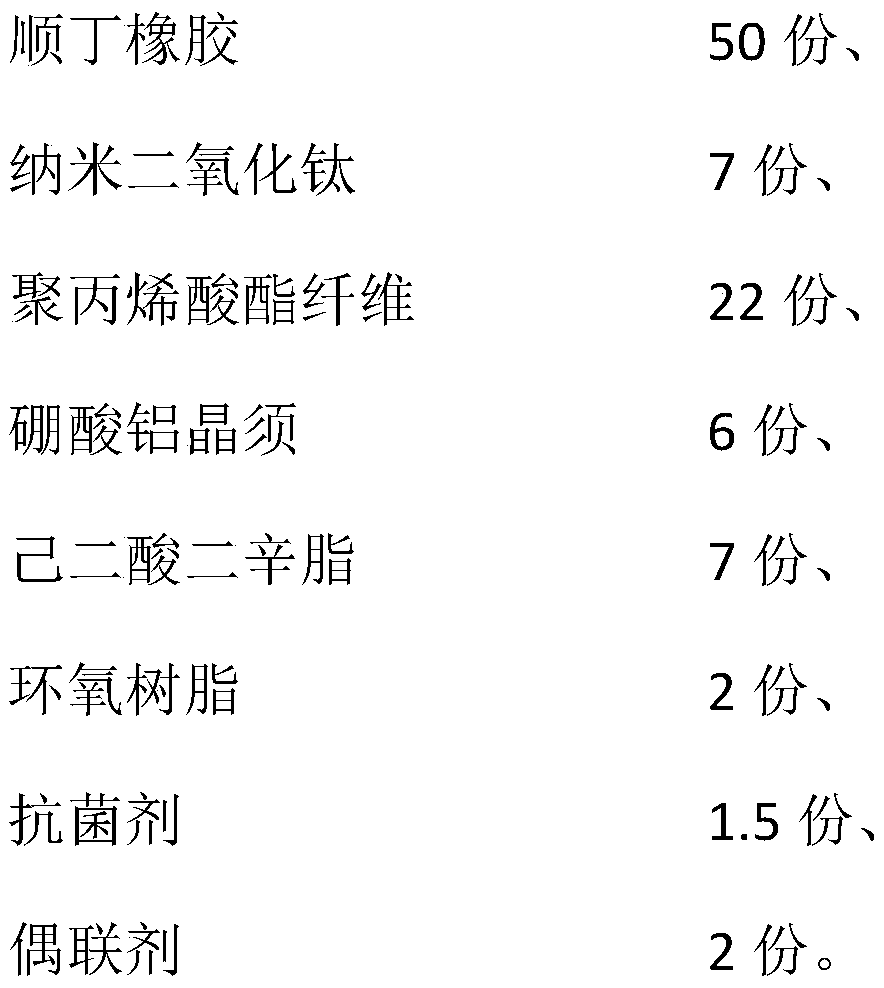

[0021] A color-changing bionic car seat cover material made from the following raw materials by weight:

[0022]

[0023]

[0024] The antibacterial agent includes nano-silver, zinc oxide and silicon dioxide, and the weight ratio of nano-silver, zinc oxide and silicon dioxide is 4:3:1.

[0025] A method for manufacturing a color-changing bionic car seat cover material, comprising the following steps: weighing 40 parts of polyethylene, 2 parts of nano silicon dioxide, 4 parts of zinc oxide, 6 parts of viscose fiber, and butyl rubber 17 parts, 50 parts of butadiene rubber, 7 parts of nano-titanium dioxide, 22 parts of polyacrylate fiber, 6 parts of aluminum borate whiskers, 7 parts of dioctyl adipate, 2 parts of epoxy resin, 1.5 parts of antibacterial agent, coupling 2 parts of the agent were mixed and added to a mixer, and stirred for 40 minutes at a temperature of 115° C. and a rotation speed of 2700 r / min to obtain a seat cover material.

Embodiment 2

[0027] A color-changing bionic car seat cover material made from the following raw materials by weight:

[0028]

[0029]

[0030] The antibacterial agent includes nano-silver, zinc oxide and silicon dioxide, and the weight ratio of nano-silver, zinc oxide and silicon dioxide is 4:3:1.

[0031] A method for manufacturing a color-changing bionic car seat cover material, comprising the following steps: weighing 40 parts of polyethylene, 2 parts of nano silicon dioxide, 4 parts of zinc oxide, 6 parts of viscose fiber, and butyl rubber 17 parts, 50 parts of butadiene rubber, 7 parts of nano-titanium dioxide, 22 parts of polyacrylate fiber, 6 parts of aluminum borate whiskers, 7 parts of dioctyl adipate, 2 parts of epoxy resin, 1.5 parts of antibacterial agent, coupling 2 parts of the agent were mixed and added to a mixer, and stirred for 30 minutes at a temperature of 100° C. and a rotation speed of 2500 r / min to obtain a seat cover material.

Embodiment 3

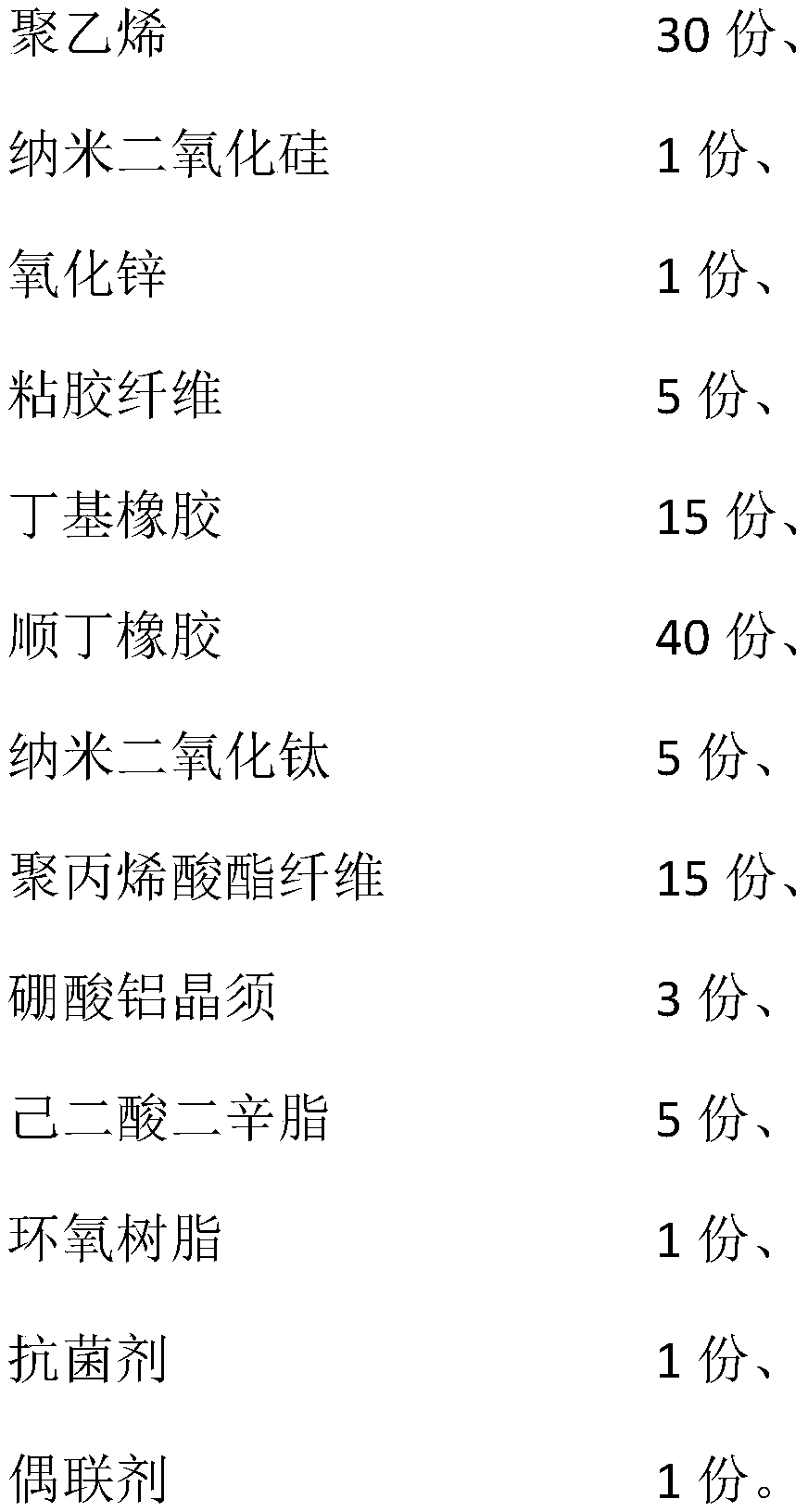

[0033] A color-changing bionic car seat cover material made from the following raw materials by weight:

[0034]

[0035]

[0036] The antibacterial agent includes nano-silver, zinc oxide and silicon dioxide, and the weight ratio of nano-silver, zinc oxide and silicon dioxide is 4:3:1.

[0037] A method for manufacturing a color-changing bionic car seat cover material, comprising the following steps: weighing 40 parts of polyethylene, 2 parts of nano silicon dioxide, 4 parts of zinc oxide, 6 parts of viscose fiber, and butyl rubber 17 parts, 50 parts of butadiene rubber, 7 parts of nano-titanium dioxide, 22 parts of polyacrylate fiber, 6 parts of aluminum borate whiskers, 7 parts of dioctyl adipate, 2 parts of epoxy resin, 1.5 parts of antibacterial agent, coupling 2 parts of the agent were mixed and added to a mixer, and stirred for 50 minutes at a temperature of 130° C. and a rotation speed of 3000 r / min to obtain a seat cover material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com