Front and back double-sided anti-static composite release film

A double-sided, antistatic technology, applied in conductive coatings, coatings, epoxy resin coatings, etc., can solve the problems of dust absorption, affecting processing quality, and damage to electronic components, etc., to achieve strong antistatic ability and avoid The effect of charge accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

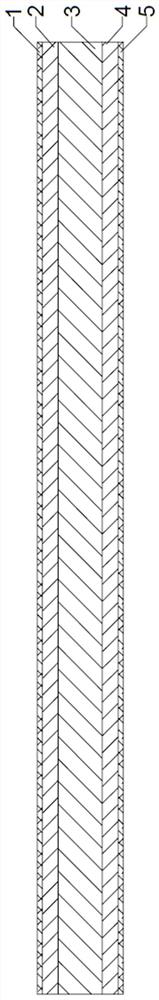

[0029] Such as figure 1 The front and back double-sided antistatic composite release film shown, from top to bottom, includes front release agent coating 1, front antistatic layer 2, substrate original film layer 3, back antistatic layer 4, back release Forming agent coating 5; The thickness of the original film layer 3 of the substrate is 70 μm; The thickness of the front antistatic layer 2 and the back antistatic layer 4 is 25 μm; The front release agent coating 1 and the back release The thickness of the agent coating 5 is 8 μm.

[0030] Wherein, the base material original film layer is a composite film composed of PET, PE, and PI, which includes the following components by weight ratio: 60 parts of PET particles, 25 parts of PP particles, and 20 parts of PI particles.

[0031] Moreover, the front antistatic layer includes the following components by weight: 25 parts of carbon nanotubes, 35 parts of epoxy resin, 9 parts of silicone oil, 2 parts of defoaming agent, 2 parts ...

Embodiment 2

[0039] A double-sided antistatic composite release film, which includes, from top to bottom, a front release agent coating 1, a front antistatic layer 2, a substrate original film layer 3, a reverse antistatic layer 4, and a reverse release film. Agent coating 5; The thickness of the original film layer 3 of the substrate is 30 μm; The thickness of the front antistatic layer 2 and the back antistatic layer 4 is 15m; The front release agent coating 1 and the back release agent The coating 5 has a thickness of 4 μm.

[0040] Wherein, the base material original film layer is a composite film composed of PET, PE, and PI, which includes the following components by weight ratio: 50 parts of PET particles, 15 parts of PP particles, and 10 parts of PI particles.

[0041] In addition, the front antistatic layer includes the following components by weight: 20 parts of carbon nanotubes, 30 parts of epoxy resin, 5 parts of silicone oil, 0.5 parts of defoaming agent, 0.5 parts of leveling ...

Embodiment 3

[0049] A double-sided antistatic composite release film, which includes, from top to bottom, a front release agent coating 1, a front antistatic layer 2, a substrate original film layer 3, a reverse antistatic layer 4, and a reverse release film. Agent coating 5; The thickness of the original film layer 3 of the substrate is 50 μm; The thickness of the front antistatic layer 2 and the back antistatic layer 4 is 20 μm; The front release agent coating 1 and the back release agent The thickness of the coating 5 is 6 μm.

[0050] Wherein, the original film layer of the base material is a composite film composed of PET, PE, and PI, which includes the following components by weight ratio: 55 parts of PET particles, 20 parts of PP particles, and 15 parts of PI particles.

[0051] Moreover, the front antistatic layer includes the following components by weight: 22.5 parts of carbon nanotubes, 32.5 parts of epoxy resin, 7 parts of silicone oil, 1.25 parts of defoaming agent, 1.25 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com