Self-heat-dissipation rare earth permanent magnet synchronous motor

A rare-earth permanent magnet and synchronous motor technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of affecting the actual effect of the motor, reducing the effect of the heat sink, and being unable to further improve the heat dissipation effect of the synchronous motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

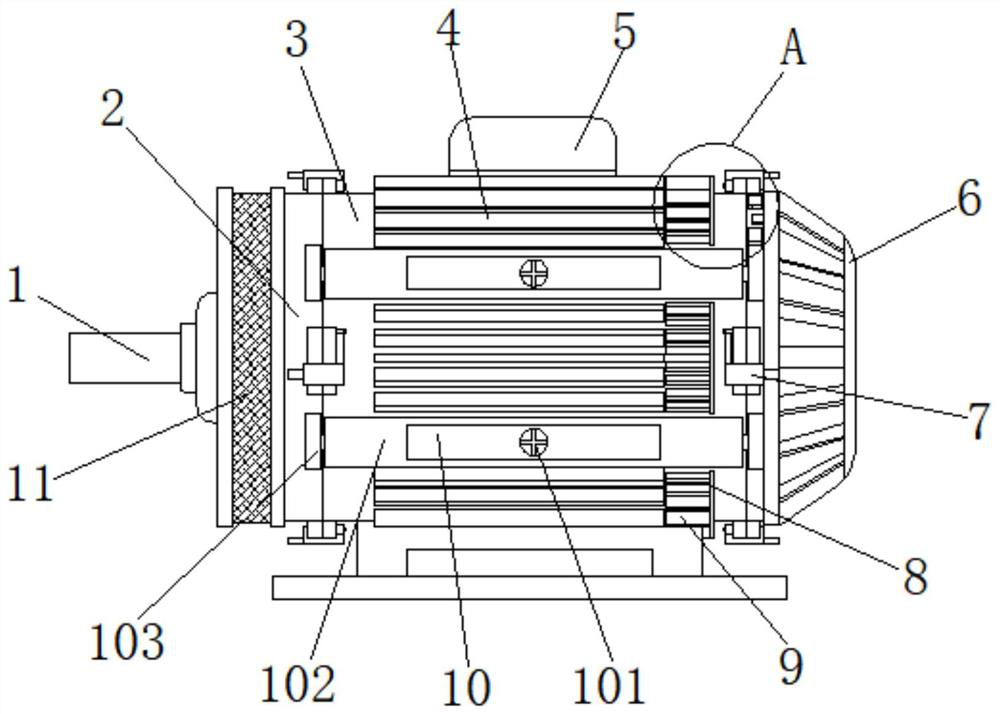

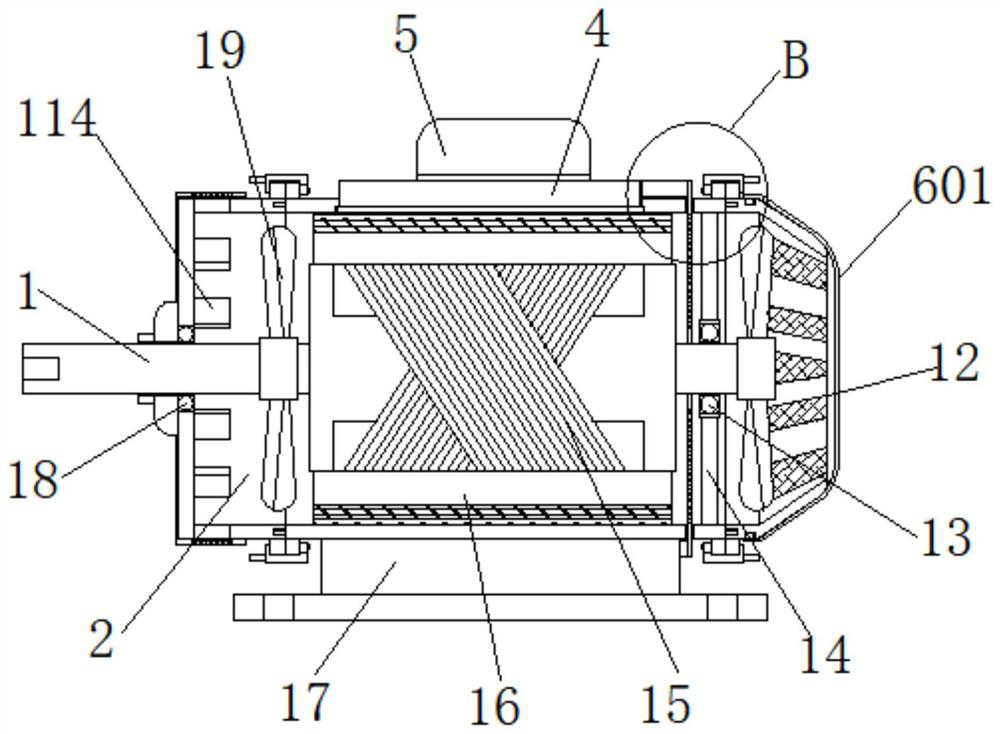

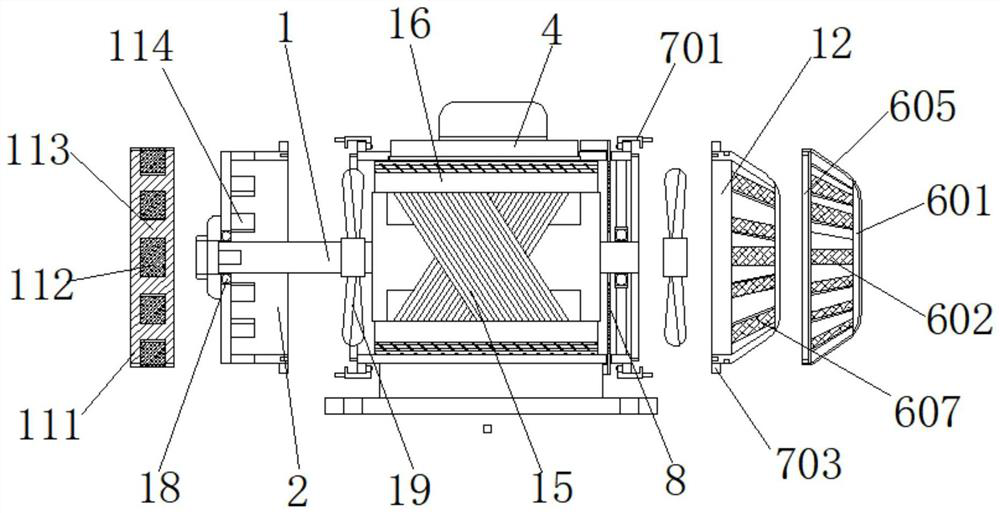

[0034] Example 1, such as Figure 1-3 As shown, when the outside air needs to be sucked into the interior of the machine compartment 3, the internal thread ring 113 can be rotated so that the through groove A111 and the through groove B114 can overlap, so that the outside air can pass through the filter screen B112 after being filtered. The through groove A111 and the through groove B114 enter the inside of the machine compartment 3, and then the outer cover 601 is rotated so that the strip-shaped through holes 602 on the outer cover 601 and the rear cover 12 overlap each other, so that the air in the machine compartment 3 can flow from the bar Shaped through hole 602 out to the external environment.

Embodiment 2

[0035] Example 2, such as figure 1 , 5 As shown in and 7, when the rare earth permanent magnet synchronous motor needs to be disassembled and overhauled, the four sets of bolts 101 are first unscrewed, and the elastic restoring force of the spring 105 forces the mounting plate 104 and multiple sets of bolts 109 to rise, so that the bolts 109 leave Inside the pin groove 108, then manually pull multiple groups of U-shaped card holders 701 apart, and then pull the front cover 2 and the rear cover 12 to the end away from the machine compartment 3, so that the front cover 2 and the rear cover 12 are The inserting rod 107 is gradually extracted from the inside of the slot 102, thereby completing the dismounting of the front cover 2 and the rear cover 12, and then the front cover 2 and the rear cover 12 are fixedly installed again after the inside of the motor is overhauled.

Embodiment 3

[0036] Example 3, such as figure 2 , 3 , 4, 6 and 7, when the rare earth permanent magnet synchronous motor is in use, the motor shaft 1 drives two sets of fans 19 to rotate. During the working process of the motor, the rotor 15 and the stator winding 16 gradually generate a large amount of heat, and the stator The heat on the outside of the winding 16 is gradually transferred to multiple sets of cooling fins A4, and the exposed parts of the cooling fins A4 outside the machine compartment 3 increase the heat dissipation area and improve the heat dissipation effect. The rotation of the fan 19 makes the outside air enter the machine compartment 3 through the slot A111 Inside, the surface of the rotor 15 and the stator winding 16 is blown to cool down, and when the air with temperature passes through the annular heat conduction fin 8, a part of the heat is transferred to the heat sink B9 outside the machine compartment 3 through the annular heat conduction fin 8 , so that the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com