An automated building material hoist

A hoist and building technology, applied in building construction, building material processing, construction, etc., can solve problems such as low efficiency, time-consuming and labor-intensive, and achieve a high level of automation and save manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

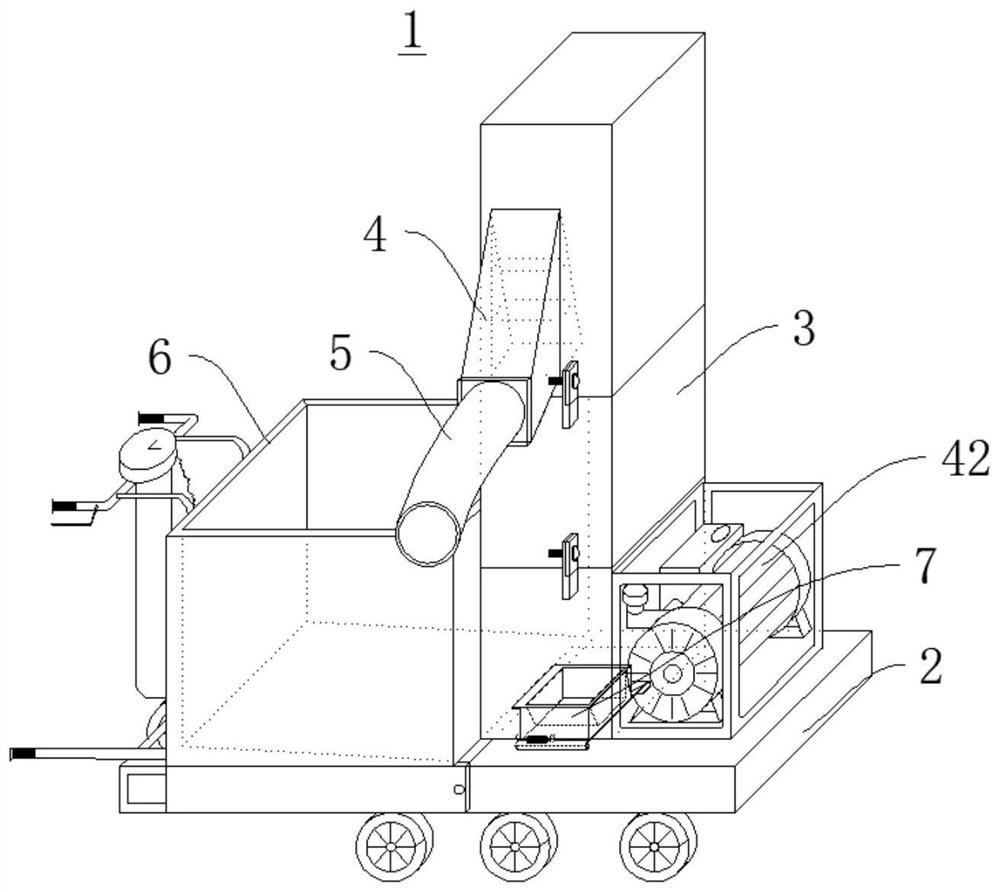

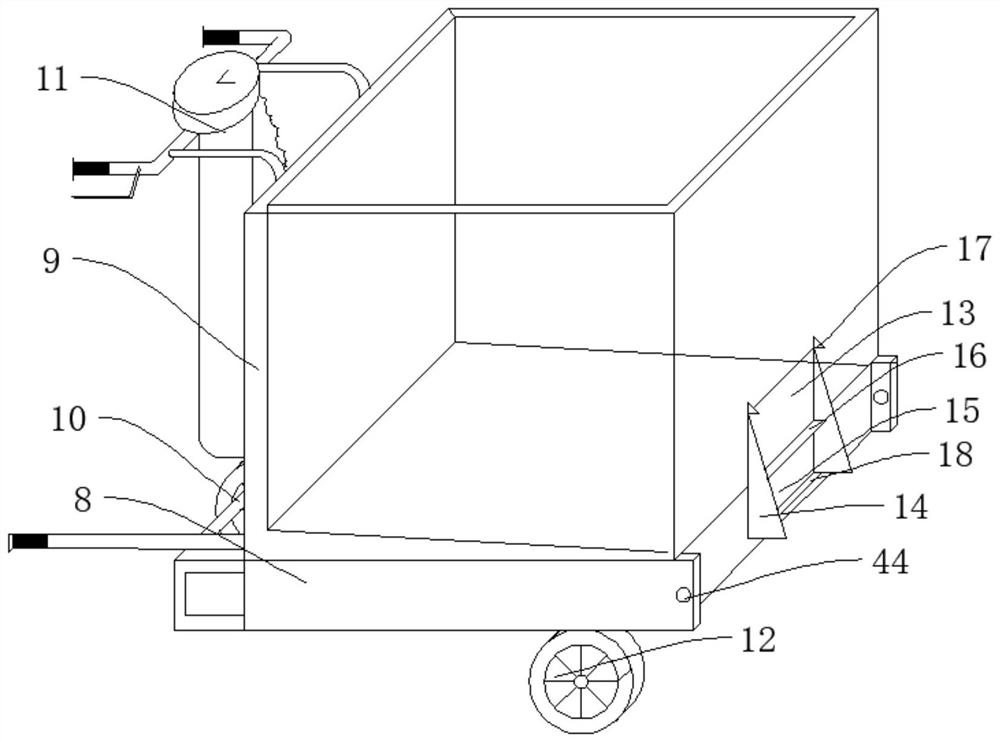

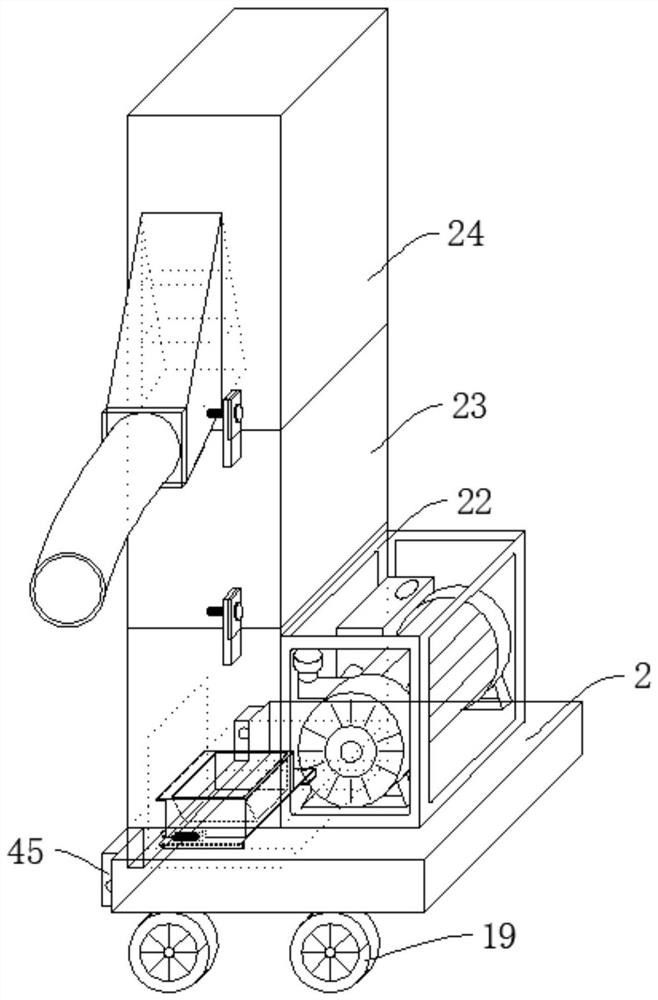

[0052] Please refer to figure 1 , with reference to Figure 2 to Figure 21 , the present application provides an automated building material hoist 1, which mainly includes a movable base 2, a hollow discharge casing 3 mounted on the base 2, a movable electric feeding hopper car 6 and a self-elevating conveyor. Material mechanism 7; Wherein, the height of discharging casing 3 is adjustable, and it is the box body structure of interior hollow, is communicated with discharging square groove 4 at the top side place of discharging casing 3, and the discharge square groove 4 The cross-section is a T-shaped structure, which is inclined downwards, and a port is opened on a rectangular plate on one side of the discharge square groove 4, through which the port is fixedly installed on the first discharge port on the upper part of the discharge casing 3, And communicate with the first discharge port, the square plate on the other opposite side of the discharge square groove 4 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com